OEM vs Aftermarket Excavator Parts: What to Choose

- OEM vs Aftermarket Excavator Parts: What to Choose

- Why the choice of excavator parts matters

- Key terms and context: OEM, aftermarket, remanufactured

- How to evaluate excavator parts: 7 critical criteria

- Side-by-side comparison: OEM vs Aftermarket (quick reference)

- Sources for the comparison

- When OEM parts are the best choice

- When aftermarket parts make sense

- Case study: SPARKLING MACHINERY ZGAQ-03591 Hub for Hyundai excavators

- Why this product is relevant to the OEM decision

- Practical procurement checklist: how to vet a part or supplier

- Maintenance and installation considerations

- Financial perspective: how to compare lifecycle costs (TCO)

- Regulatory and safety compliance

- Brand summary: why choose SPARKLING MACHINERY for Hyundai parts

- Simple decision guide: pick OEM when...

- Pick aftermarket when...

- FAQ

- Q: Are aftermarket hubs safe for heavy-duty Hyundai excavators?

- Q: How much cheaper are aftermarket excavator parts?

- Q: Will using aftermarket parts void my machine warranty?

- Q: How do I verify a supplier's claim that a part meets an OEM part number like ZGAQ-03591?

- Q: What is the best procurement strategy for mixed fleets?

- Contact and next steps

- Sources

OEM vs Aftermarket Excavator Parts: What to Choose

Why the choice of excavator parts matters

Choosing between OEM (Original Equipment Manufacturer) and aftermarket excavator parts affects machine uptime, safety, repair cost, resale value, and total cost of ownership (TCO). For heavy construction and mining equipment, such as Hyundai wheeled and tracked excavators, the right parts choice can prevent unexpected failures, reduce downtime, and protect operator safety. This guide walks through the technical, financial, and practical factors to help fleet managers, mechanics, and procurement teams make the right decision for each repair or overhaul. With the choice between OEM and aftermarket excavator parts clarified, it's now important to consider the maintenance checklist for Hyundai R160W9A excavators. Regular maintenance can prevent part failures and ensure the longevity of your equipment, regardless of the type of parts you use.

Key terms and context: OEM, aftermarket, remanufactured

Before diving into pros and cons, here are clear definitions to avoid confusion:

- OEM parts: Parts manufactured or authorized by the original equipment maker (e.g., Hyundai Genuine Parts). They match the original specifications and usually carry OEM warranties.

- Aftermarket parts: Parts produced by third-party manufacturers not affiliated with the OEM. Quality and fitment vary widely — from aftermarket replicas to improved designs.

- Remanufactured parts: Used components that are disassembled, cleaned, inspected, and rebuilt to meet a specified standard. Reman can be offered by OEMs or independent shops.

How to evaluate excavator parts: 7 critical criteria

When deciding between OEM and aftermarket, evaluate parts using consistent criteria:

- Compatibility and fit: Does the part match the original part number and tolerances?

- Material and durability: Are materials, heat treatments, and surface coatings equivalent?

- Warranty and support: What warranty length and technical support are offered?

- Availability and lead time: How quickly can you get the part for emergency repairs?

- Price and TCO: Consider repair frequency, downtime cost, and lifespan—not just sticker price.

- Compliance and safety: Does the part meet regulatory and operational safety standards?

- Vendor credibility: Does the supplier have traceability, batch records, and references?

Side-by-side comparison: OEM vs Aftermarket (quick reference)

The table below summarizes typical differences for excavator parts. Individual vendors may deviate.

| Aspect | OEM Parts | Aftermarket Parts | Notes / Source |

|---|---|---|---|

| Fit & Compatibility | Exact fit to OEM specs | Can vary; some are exact-fit, others are generic | OEM datasheets; aftermarket variability reported by industry reviews |

| Quality & Materials | Controlled by OEM standards and QA | Wide range: from equal to inferior, occasional superior designs | ISO 9001 and OEM quality systems |

| Warranty | Typically longer and clearer (OEM warranty) | Shorter or conditional warranties | Manufacturer policies |

| Price | Higher initial cost | Lower initial cost | Impact on TCO depends on lifetime and downtime |

| Availability | May be slower if parts are scarce | Often faster due to multiple suppliers | Critical for emergency repairs |

| Traceability | Clear serials and traceable production | Varies by vendor; some offer full traceability | Important for safety and audits |

Sources for the comparison

- Caterpillar: Why Use Genuine Parts? (industry OEM guidance)

- ISO 9001: Quality management principles (quality control context)

- Industry procurement and parts articles about aftermarket variability

When OEM parts are the best choice

Choose OEM parts when the priority is reliability, safety, machine life conservation, or when operating under tight warranty, compliance, or contractual obligations. Specific situations include:

- Critical load-bearing parts or safety components (e.g., hubs, pins, structural castings).

- Machines under OEM service agreements or warranty.

- High-hour, heavy-duty applications where a failure would cause major downtime or safety risk.

- Resale preparation: buyers often value documented OEM parts and service history.

Example: For Hyundai R160W9A and R170W7-series excavators, selecting an OEM-spec hub that meets Hyundai part number ZGAQ-03591 helps ensure proper load distribution and long-term compatibility.

When aftermarket parts make sense

Aftermarket parts are a valid choice when cost control and quick availability are the priority and when the vendor is reputable. Typical scenarios:

- Non-critical wear items where failure does not compromise safety (filters, seals, some hydraulic hoses).

- Older machines out of OEM support where OEM parts are discontinued or prohibitively expensive.

- Large fleets that require lower upfront cost and can accept modest variation in part life if it lowers TCO.

- When aftermarket vendors provide documented testing, material certificates, and reliable warranties.

Case study: SPARKLING MACHINERY ZGAQ-03591 Hub for Hyundai excavators

Below is a real-world example to show how a specific product fits into the OEM vs aftermarket decision.

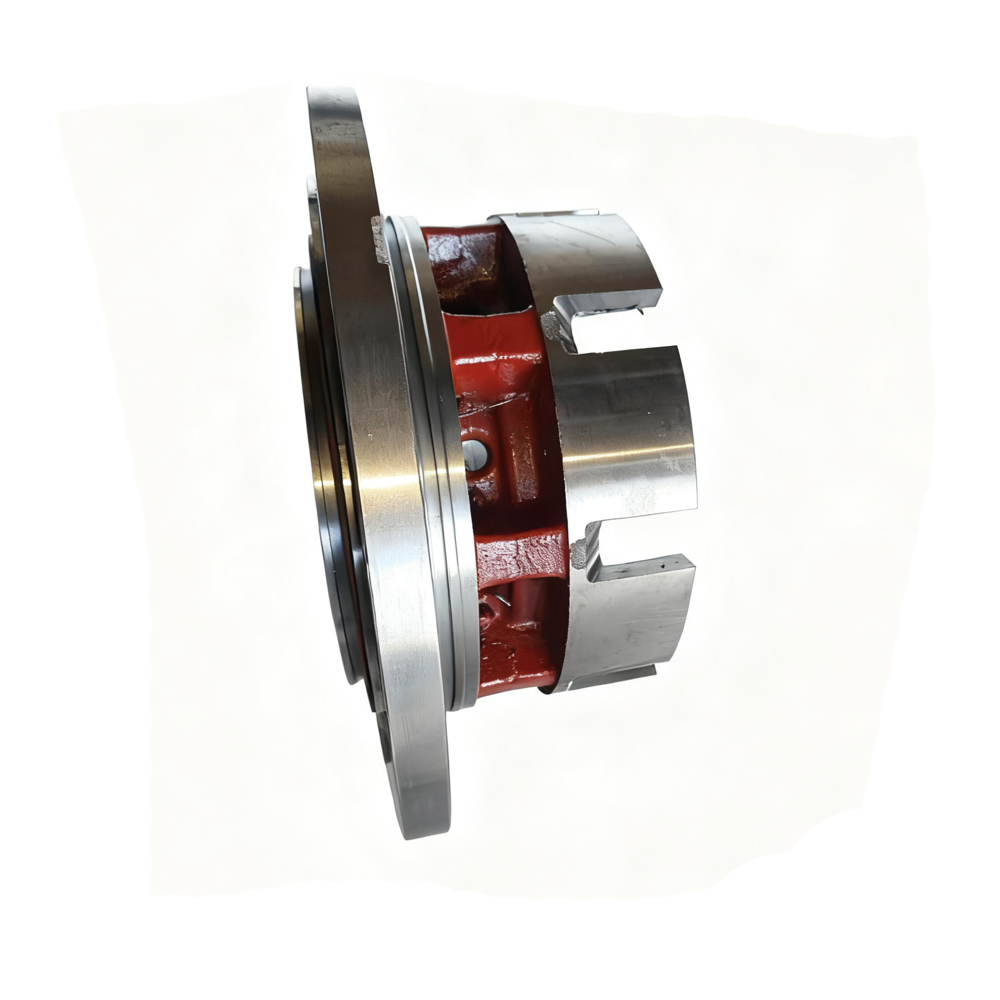

SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub is a core undercarriage component for Hyundai R160W9A/R170W7/R170W7A/R170W9 excavators (heavy-duty construction/mining use). It connects the excavator’s track system to the axle, supporting load and ensuring stable travel.

Meeting Hyundai OEM standards (ZGAQ-03591), it resists -30°C to 100°C temps, wear, and impact, ensuring seamless compatibility and long-term reliable load-bearing performance.

Why this product is relevant to the OEM decision

This SPARKLING MACHINERY hub claims to meet Hyundai OEM standards and lists ZGAQ-03591 as a reference. If independently verified, such a part sits in a hybrid category: an aftermarket-sourced part manufactured to OEM specifications. For procurement teams this can deliver the best of both worlds — OEM-level fit and performance at more competitive pricing — but verification steps (material certificates, batch traceability, sample testing) are essential.

Practical procurement checklist: how to vet a part or supplier

Follow these steps when evaluating a specific part or vendor:

- Verify the part number and cross reference with OEM parts manual.

- Request material certificates and manufacturing process details.

- Ask for test records: hardness tests, dimensional inspection, non-destructive testing (if applicable).

- Confirm warranty length, exclusions, and return policy.

- Check lead times and spare availability for planned maintenance.

- Ask for references from other fleets who used the same part.

- When possible, perform a trial on a non-critical machine before fleet-wide adoption.

Maintenance and installation considerations

Installation quality and maintenance practices are as important as part selection. Even an OEM part can fail prematurely if installed incorrectly. Key tips:

- Use trained technicians and follow torque and assembly procedures in the service manual.

- Inspect mounting surfaces and mating parts for wear before installing a replacement hub or structural part.

- Use correct lubricants and seals to prevent contamination and premature wear.

- Document the replacement in maintenance records to preserve warranty and resale value.

Financial perspective: how to compare lifecycle costs (TCO)

Compare not only purchase price but also expected life, downtime costs, and labor for replacements. A higher-priced OEM hub that lasts twice as long may be cheaper per operating hour than a low-cost aftermarket hub that requires frequent replacement.

Typical TCO formula includes: purchase price + installation labor + downtime cost per hour * expected downtime frequency + disposal/replacement costs. Include probability of catastrophic failure cost for critical parts.

Regulatory and safety compliance

For machines operating under regulated contracts or in jurisdictions with strict safety audits, OEM or OEM-equivalent parts with clear traceability are often required. Ensure parts conform to relevant standards and keep documentation on file; this is important for accident investigations and insurance claims.

Brand summary: why choose SPARKLING MACHINERY for Hyundai parts

SPARKLING MACHINERY positions itself as a supplier of high-quality excavator parts made in China with a focus on compatibility for Hyundai models R160W9A, R170W7, R170W7A, and R170W9. The primary advantages to highlight:

- Claims of OEM-spec manufacturing to match Hyundai part number ZGAQ-03591.

- Temperature and impact-rated components for heavy-duty use (-30°C to 100°C performance).

- Potential cost benefits compared to direct OEM channels while maintaining fit and function.

- Availability for rapid replacement needs where OEM lead time may be long.

These strengths make SPARKLING MACHINERY a practical option when the company provides traceability, test certificates, and warranty terms. Always verify documentation before fleet-wide adoption.

Simple decision guide: pick OEM when...

- You need guaranteed fit and long-term support from the OEM.

- Part is critical to safety, structural integrity, or is hard to replace in the field.

- You are under an OEM maintenance contract or warranty.

Pick aftermarket when...

- Cost and fast delivery are top priorities and the part is non-critical.

- Vendor provides documentation, testing, and a credible warranty.

- Machine is out of OEM support and aftermarket offers practical alternatives.

FAQ

Q: Are aftermarket hubs safe for heavy-duty Hyundai excavators?

A: They can be if manufactured to OEM specifications and supported by material and test documentation. For safety-critical hubs, insist on traceability, NDT reports, and hardness or tensile data. When in doubt, use an OEM part.

Q: How much cheaper are aftermarket excavator parts?

A: Price difference varies widely by part and supplier. For some wear items, aftermarket prices can be 20–60% lower; for major structural parts the gap narrows if aftermarket vendors use OEM-grade materials. Evaluate on a per-part TCO basis.

Q: Will using aftermarket parts void my machine warranty?

A: Warranty policies vary. Some OEMs allow aftermarket parts but exclude failures caused by those parts. Always check the OEM warranty terms and document installation and vendor warranties.

Q: How do I verify a supplier's claim that a part meets an OEM part number like ZGAQ-03591?

A: Ask for cross-reference documentation, dimensional inspection reports, material certificates, and a sample for fit verification. Independent metal lab testing can confirm material properties when critical.

Q: What is the best procurement strategy for mixed fleets?

A: Adopt a parts policy: OEM for safety-critical and high-hour applications; vetted aftermarket for low-risk wear items. Keep a preferred-supplier list and run pilot trials before large purchases.

Contact and next steps

If you want a direct comparison or documentation for the SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub, contact our parts team for certificates, test data, and price quotes. View the product, request a sample, or speak with a technical specialist to validate fitment and warranty terms.

Contact us to request the product datasheet, test certificates, and pricing. View product details or get a quote now.

Sources

- Why use genuine parts? Caterpillar - https://www.cat.com/en_US/support/maintenance/parts-service/parts/genuine-parts.

- ISO 9001 — Quality management systems — https://www.iso.org/iso-9001-quality-management.

- Heavy equipment safety guidance, OSHA eTools - https://www.osha.gov/etools/construction/heavy-equipment

- Aftermarket parts industry discussion, ForConstructionPros - https://www.forconstructionpros.com/parts-equipment

- Hyundai Construction Equipment global site for parts reference - https://www.hyundai-ce.com

How Taper Roller Bearings Impact Excavator Performance

Best professional OEM excavator parts manufacturers and supplier brands

Best reduction gear excavator manufacturers and supplier brands

Best professional excavator undercarriage parts manufacturers and supplier brands

faq

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

SPARKLING MACHINERY NEW WA380 WA420 WA450 424-64-15610 Hydraulic Valve is a dedicated, high-precision control component exclusively engineered for KOMATSU WA380, WA420, and WA450 wheel loaders—equipment widely paired with excavators in construction, mining, and logistics for efficient material handling. As the core of the wheel loader’s hydraulic system, it precisely regulates hydraulic oil flow and pressure to control key functions (lift arm elevation, bucket tilting, steering), ensuring smooth, responsive operation during tasks like bulk material loading, stockpiling, and on-site material transfer. This function is vital for preventing hydraulic flow misdirection, maintaining operational accuracy, and avoiding unplanned downtime that disrupts coordinated excavator-loader workflows.

- Compatibility: It is compatible with several Komatsu models, including the WA380-3, WA420-3, WA450-3, WA470-3, and WF450 wheel loaders.

Excavator Spare Parts 9V battery XZFK-404 DIGITAL FLOW METER

SPARKLING MACHINERY NEW XZFK-404 Digital Flow Meter is a premium China-made fluid monitoring component designed for compatible construction machinery, hydraulic systems, and industrial fluid circuits—including those in excavators, loaders, and hydraulic power units. As the "fluid measurement guardian" of machinery systems, it accurately detects and displays real-time flow rates of hydraulic oil, coolant, or other industrial fluids, with a measurement range tailored to heavy-duty equipment needs. This enables operators and maintenance teams to monitor fluid circulation efficiency, identify abnormal flow (e.g., leaks, blockages), and optimize system performance—critical for preventing hydraulic component damage, reducing energy waste, and ensuring stable operation in construction, mining, and industrial scenarios.

Engineered to original equipment standards, it maintains high measurement accuracy even under harsh working conditions: high hydraulic pressure (up to 35 MPa), temperature fluctuations (-20°C to 80°C), vibration, and exposure to dust or hydraulic fluid contaminants. With a clear digital display (for easy readability) and a robust, corrosion-resistant housing, it resists environmental wear and ensures long-term reliability. Backed by strict quality verification, it guarantees precise fluid data to support proactive maintenance and minimize downtime caused by fluid system failures.

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW GF950194 SOLENOID ASSY SPARKLING MACHINERY

SPARKLING MACHINERY NEW GF950194 Solenoid Assy is a core electromagnetic control component for Caterpillar excavators (heavy-duty construction/mining use). It converts electrical signals into mechanical motion to control fluid flow or mechanical switches, ensuring precise system operation.

Meeting Caterpillar OEM standards (GF950194), it resists -30°C to 100°C temps, electromagnetic interference, and wear, ensuring seamless compatibility and long-term reliable control performance.

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 GEAR-COUPLING SPARKLING MACHINERY

SPARKLING MACHINERY NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 Gear-Coupling is a core power transmission component for 3 Hyundai excavator models (construction/mining use). It connects and transmits torque between mechanical shafts, absorbing vibration and compensating for alignment deviations.

Meeting Hyundai OEM standards (XKAH-00360), it resists -30°C to 100°C temps, wear, and impact, guaranteeing seamless compatibility and long-term reliable transmission performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879