Material and Pressure Ratings for Hydraulic Hose VOE14578951

- Material and Pressure Ratings for Hydraulic Hose VOE14578951

- Why choosing the right hydraulic hose matters for your Volvo EC480D fleet — buy hydraulic hose with confidence

- Product overview: Hydraulic Hose For Volvo Construction Equipment models EC480D EC480DHR VOE14578951 14578951 — hydraulic hose replacement

- Materials and construction of VOE14578951 hydraulic hose — multi-layered reinforced synthetic rubber

- Outer cover and abrasion resistance — hydraulic hose for harsh environments

- Reinforcement layers and braid/spiral construction — pressure handling and impulse resistance of hydraulic hose

- Pressure ratings and temperature ranges — rated working and burst pressures for VOE14578951 hydraulic hose

- Impulse resistance and cycle life — maximizing hose longevity for VOE14578951

- Compatibility: fluids, seals and environmental resistance — hydraulic hose fluid compatibility

- Installation, inspection and maintenance recommendations — hydraulic hose replacement best practices

- Testing, certification and standards — SAE J517, ISO 1436 and EN standards for hydraulic hose

- How to buy and replace VOE14578951 — VOE14578951 for sale and procurement guidance

- Brand advantages — why choose SPARKLING MACHINERY for Hydraulic Hose VOE14578951

- FAQ — Common questions about VOE14578951 hydraulic hose

- Q: What is the working pressure of VOE14578951?

- Q: Is VOE14578951 compatible with all hydraulic fluids?

- Q: How often should VOE14578951 be inspected or replaced?

- Q: Are these hoses sold pre-assembled with fittings?

- Q: How does VOE14578951 compare to generic hydraulic hoses?

- Contact us / View Product — order VOE14578951 hydraulic hose

- References and authoritative sources

Material and Pressure Ratings for Hydraulic Hose VOE14578951

Why choosing the right hydraulic hose matters for your Volvo EC480D fleet — buy hydraulic hose with confidence

Hydraulic hoses are mission-critical components on heavy construction machines such as the Volvo EC480D and EC480DHR. A hose failure can cause equipment downtime, environmental contamination, safety hazards and costly repairs. Selecting a hose engineered for the pressure, temperature, fluid compatibility and abrasion encountered by 50-ton class excavators ensures sustained hydraulic performance, predictable maintenance intervals and operator safety. This article explains the materials and pressure ratings of the VOE14578951 Hydraulic Hose and provides practical guidance for buyers, maintenance teams and fleet managers.

Product overview: Hydraulic Hose For Volvo Construction Equipment models EC480D EC480DHR VOE14578951 14578951 — hydraulic hose replacement

Ensure peak hydraulic efficiency for your heavy-duty fleet with the VOE14578951 Hydraulic Hose, exclusively supplied by SPARKLING MACHINERY. This High Quality hose is specifically engineered for high-pressure applications in Volvo’s large-scale excavators and pipelayers. Fabricated from multi-layered reinforced synthetic rubber, our VOE14578951 hose is built to withstand extreme pressure fluctuations and abrasive environments. Whether your EC480D is working in a quarry or your EC480DHR is engaged in high-reach demolition, this hose ensures zero-leakage performance and long-term reliability.

Key Specifications:

OEM Part Number: VOE14578951 / 14578951.

Enhanced Durability: Resistant to oil, weather, and high-impulse hydraulic cycles.

Exact Fitment: Designed as a direct replacement for Volvo EC480D series, ensuring easy installation.

High Pressure Rated: Engineered for the demanding hydraulic demands of 50-ton class machinery.

Supported Equipment: Excavators: EC480D, EC480DHR (High Reach Demolition). Pipelayers: PL4809D.

Materials and construction of VOE14578951 hydraulic hose — multi-layered reinforced synthetic rubber

The VOE14578951 is built using a layered construction optimized for heavy-duty hydraulic service. Typical components are:

- Inner tube: oil-resistant synthetic rubber compound formulated for compatibility with hydraulic fluids (mineral oils, specific synthetic fluids per OEM specs).

- Reinforcement: multi-layered braided and/or spiral steel wire reinforcement provides high working pressure capacity and excellent impulse resistance.

- Cover: abrasion- and weather-resistant synthetic rubber with ozone and UV inhibitors to extend field life in outdoor applications.

This combination balances flexibility, pressure capability and abrasion resistance. Multi-layer steel reinforcement is the industry standard for high-pressure lines on large excavators where both burst and dynamic impulse resistance are critical.

Outer cover and abrasion resistance — hydraulic hose for harsh environments

Construction equipment hoses operate in rock, sharp debris and underwater conditions. The VOE14578951 outer cover uses a tough, oil- and abrasion-resistant rubber compound and textured cover pattern to reduce wear from chafing and contact. When selecting hose routing or protective sleeves, consider additional abrasion guards in high-wear paths to maximize service life.

Reinforcement layers and braid/spiral construction — pressure handling and impulse resistance of hydraulic hose

Reinforcement determines how a hose responds to continuous high-pressure and rapid pressure spikes (impulse). Braided reinforcement offers greater flexibility, while spiral or multi-spiral wire reinforcement provides superior resistance to high, continuous working pressures and bursting. VOE14578951 assemblies for EC480D class machines typically use spiral steel wire reinforcement to meet the higher working pressure and impulse life required by heavy hydraulic circuits.

Pressure ratings and temperature ranges — rated working and burst pressures for VOE14578951 hydraulic hose

Pressure rating terminology:

- Working Pressure (WP): The maximum continuous pressure the hose is designed to carry during normal operation.

- Test/Proof Pressure: A higher pressure used during testing to verify integrity after assembly or repair (often 1.3–1.5× WP).

- Burst Pressure: Minimum pressure at which the hose is expected to burst—manufacturers typically design a safety factor (commonly 4:1 WP:burst for hydraulic hoses used on heavy equipment).

Typical pressure and temperature ratings for VOE14578951 (representative values — confirm with product datasheet for exact size-specific ratings):

| Hose Size (example) | Nominal ID (inch / mm) | Typical Working Pressure (WP) | Typical Test/Proof Pressure | Typical Burst Pressure (min) | Temperature Range |

|---|---|---|---|---|---|

| Size A (common pilot/feed) | 1/2 (12.7 mm) | 4,000 psi (275 bar) | 6,000 psi (414 bar) | 16,000 psi (1,100 bar) | -40°C to +120°C (-40°F to +248°F) |

| Size B (return/actuator) | 5/8 (16 mm) | 4,000–4,500 psi (275–310 bar) | 6,000–6,750 psi (414–465 bar) | 16,000–18,000 psi (1,100–1,240 bar) | -40°C to +120°C (-40°F to +248°F) |

| Size C (main flow, high flow) | 3/4 (19 mm) | 3,500–4,500 psi (240–310 bar) | 5,250–6,750 psi (360–465 bar) | 14,000–18,000 psi (965–1,240 bar) | -40°C to +120°C (-40°F to +248°F) |

Note: These representative numbers reflect industry practice for multi-spiral wire-reinforced hydraulic hoses used on 50-ton excavators. Exact rating values vary by hose internal diameter, reinforcement layers and assembly fittings. Always consult the manufacturer datasheet or SPARKLING MACHINERY product specifications for the VOE14578951 size you are installing.

Impulse resistance and cycle life — maximizing hose longevity for VOE14578951

Impulse life (the number of pressure cycles a hose can endure) is heavily influenced by reinforcement design and material fatigue resistance. Spiral-wired hoses designed for high-impulse circuits are tested under accelerated cycles per standards (e.g., SAE J1273 test protocols). For high-reach demolition or continuous swing applications, choose hoses specified by SPARKLING MACHINERY for high impulse life and verify assembly practices (avoid tight bends, kinking, or torsion that reduce life).

Compatibility: fluids, seals and environmental resistance — hydraulic hose fluid compatibility

The VOE14578951 inner tube compound is formulated for compatibility with common hydraulic fluids used by Volvo construction equipment: mineral oils (HLP), some synthetic hydraulic oils and biodegradable fluids when specified. Key compatibility considerations:

- Confirm fluid type: mineral oil vs phosphate ester vs synthetic — certain elastomers degrade in some fluids.

- Check seal materials in fittings and system components (NBR, FKM, HNBR) for fluid-temp compatibility.

- Consider temperature extremes and contamination (water, abrasive particles) which accelerate wear.

If your application uses specialty fluids, request a material compatibility certificate from SPARKLING MACHINERY before installation.

Installation, inspection and maintenance recommendations — hydraulic hose replacement best practices

Best practices for installing and maintaining VOE14578951 assemblies:

- Use OEM-specified hose routing to minimize abrasion, bending stress and torsion.

- Select the correct hose length: avoid excessive slack (chafing) or tightness (strain on fittings).

- Use protective sleeves at chafe points and appropriate clamps to prevent rubbing against structure.

- Inspect hoses daily for cuts, nicks, bulges, leaks and worn covers. Replace at first sign of damage.

- Record hose assemblies with manufacturing date codes to track service life; hoses exposed to high-impulse circuits may need earlier replacement schedules.

Testing, certification and standards — SAE J517, ISO 1436 and EN standards for hydraulic hose

Hoses for heavy hydraulic systems are manufactured and tested to widely accepted standards. Standards commonly referenced for hoses like VOE14578951 include:

- SAE J517 — Hydraulic Hose: provides classification, test methods and minimum burst requirements.

- ISO 1436 / EN 853 / EN 856 — International and European standards that specify hose construction, performance and test requirements.

- Manufacturer-specific quality tests — proof testing, impulse cycling and dimensional checks for each hose assembly.

SPARKLING MACHINERY supplies VOE14578951 assemblies that meet or exceed these standards; request certificates of conformity and test reports for audit and quality assurance.

How to buy and replace VOE14578951 — VOE14578951 for sale and procurement guidance

When purchasing VOE14578951 replacement hoses:

- Verify OEM part number (VOE14578951 / 14578951) and application (EC480D, EC480DHR, PL4809D).

- Request size-specific pressure ratings, proof test records and the hose assembly drawing (fittings, length, end treatments).

- Buy assemblies pre-crimped to factory specifications when possible—this minimizes installation errors and ensures rated performance.

- Prefer certified suppliers such as SPARKLING MACHINERY that provide traceability, warranty and post-sales support.

Brand advantages — why choose SPARKLING MACHINERY for Hydraulic Hose VOE14578951

SPARKLING MACHINERY’s VOE14578951 offering combines product engineering, quality control and service features that matter to fleet operators:

- Direct-fit replacements certified to OEM specifications, reducing downtime by avoiding field modifications.

- Multi-layer steel reinforcement and High Quality rubber compounds tailored for high-impulse and abrasive environments typical of EC480D and EC480DHR use.

- Comprehensive testing: proof pressure, impulse cycle verification and dimensional checks for each assembly batch.

- Technical support and installation guidance to help maintenance crews apply correct routing and protective measures.

These advantages translate to longer service life, fewer unplanned repairs and predictable maintenance budgets.

FAQ — Common questions about VOE14578951 hydraulic hose

Q: What is the working pressure of VOE14578951?

A: Working pressure depends on hose size and reinforcement. Representative working pressures range from 3,500 to 4,500 psi (240–310 bar) for sizes commonly used on EC480D-class equipment. Obtain the exact WP for your replacement hose from SPARKLING MACHINERY’s datasheet for the part number and hose size.

Q: Is VOE14578951 compatible with all hydraulic fluids?

A: The inner tube is formulated for compatibility with standard mineral-based hydraulic oils used by Volvo. If your machine uses phosphate ester or specialty synthetic fluids, confirm compatibility with SPARKLING MACHINERY before installation.

Q: How often should VOE14578951 be inspected or replaced?

A: Daily visual inspections are recommended. Replacement intervals depend on operating conditions—abrasive environments and high-impulse circuits shorten life. Track manufacturing date codes and service history; for high-stress applications, expect earlier scheduled replacements compared to low-stress return lines.

Q: Are these hoses sold pre-assembled with fittings?

A: Yes. For reliability and to ensure rated pressure performance, SPARKLING MACHINERY supplies VOE14578951 as factory-crimped assemblies with the correct fittings and assemblies for direct installation on EC480D, EC480DHR and PL4809D models.

Q: How does VOE14578951 compare to generic hydraulic hoses?

A: VOE14578951 is engineered to OEM fit and performance requirements for Volvo’s large excavators. Generic hoses may not meet the same reinforcement, proof testing or material chemistry standards, which can lead to premature failures in high-pressure, high-impulse applications.

Contact us / View Product — order VOE14578951 hydraulic hose

For datasheets, certified pressure ratings, pricing and lead times for Hydraulic Hose For Volvo Construction Equipment models EC480D EC480DHR VOE14578951 14578951, contact SPARKLING MACHINERY sales:

Email: sales@sparklingmachinery.example (replace with actual contact)

Phone: +- (ask for Heavy Equipment Hose Dept.)

Or visit our product page to view specifications, request a formal quotation and order direct assemblies.

References and authoritative sources

- Hose (fluid conveyance) — Wikipedia

- Parker Hannifin — Hydraulic Hose Catalog and Technical Guidance (technical reference for hose materials and pressure ratings)

- Gates Corporation — Hydraulic Hose Basics

- SAE J517 — Hydraulic Hose Standard (SAE International)

- ISO 1436 / Hose Standards — International Organization for Standardization

- Volvo Construction Equipment — Official site

Disclaimer: The pressures and sizes shown are representative ranges typical for multi-spiral reinforced hydraulic hoses used in 50-ton class excavators. For exact, size-specific pressure ratings and temperature limits for the VOE14578951 (14578951) you plan to purchase, always request the official product datasheet, test certificates and installation drawings from SPARKLING MACHINERY prior to procurement or installation.

Parts of Excavator: Cost Breakdown and Savings Tips 2026

Best excavator idler wheel manufacturers and supplier brands

Integrating Pressure Sensors into Hitachi Excavator Control Systems

The Role of Hydraulic Pumps in Excavator Efficiency

faq

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

VOE14562193 24V Excavator Switch – Compatible with Volvo EC140B EC290C EC460B EC55C EC60E

SPARKLING MACHINERY NEW EC140B EC140C EC160B EC160C EC180B EC180C VOE14562193 Switch is a dedicated, high-reliability electrical control component exclusively engineered for VOLVO EC140B/EC140C, EC160B/EC160C, and EC180B/EC180C crawler excavators—versatile mid-sized equipment widely used in construction, municipal engineering, and light mining projects. As a core interface for the excavator’s electrical system, it enables precise activation and control of key functions (e.g., auxiliary lights, hydraulic auxiliary systems, or safety alarms), ensuring responsive operation and operator safety during high-intensity tasks. This function is vital for maintaining smooth workflow coordination, preventing accidental function activation, and avoiding operational disruptions caused by faulty electrical controls during tasks like trench digging, material loading, or site grading.

Engineered to meet VOLVO’s original equipment (OEM) standards and marked with the genuine part number VOE14562193, the switch withstands harsh working conditions: extreme temperature fluctuations (-30°C to 70°C), water and dust ingress (IP65 protection rating), and continuous vibration from heavy-duty use. It resists electrical interference and mechanical wear, providing long-lasting control reliability for the six VOLVO crawler excavator models. Backed by strict performance verification, it guarantees seamless compatibility and safe operation for daily excavator tasks.

Volvo Excavator Control Unit 60100000 – Spare Part for EC140C, EC160C, EC170D, EC180C

SPARKLING MACHINERY NEW EC210 EC210B EC210BLC 60100000 Controller C is a dedicated, high-precision electronic control unit exclusively engineered for VOLVO EC210, EC210B, and EC210BLC crawler excavators—versatile mid-sized equipment widely used in construction, municipal engineering, and light mining projects. As the “brain” of the excavator’s operational system, it processes real-time data from sensors (engine speed, hydraulic pressure, operator inputs) to coordinate the work of core mechanisms (boom, arm, bucket) and auxiliary systems, ensuring smooth, synchronized operation during tasks like trench digging, material loading, and site grading. This function is vital for preventing operational lags, optimizing energy efficiency, and avoiding unplanned downtime caused by system miscommunication.

Engineered to meet VOLVO’s original equipment (OEM) standards and marked with the part number 60100000, the Controller C withstands harsh working conditions: extreme temperature fluctuations (-30°C to 70°C), electromagnetic interference, and continuous vibration from heavy-duty use. It maintains stable data transmission and reliable control performance, providing long-lasting operational support for the three VOLVO excavator models. Backed by strict performance verification, it guarantees seamless compatibility and safe operation for daily excavator tasks.

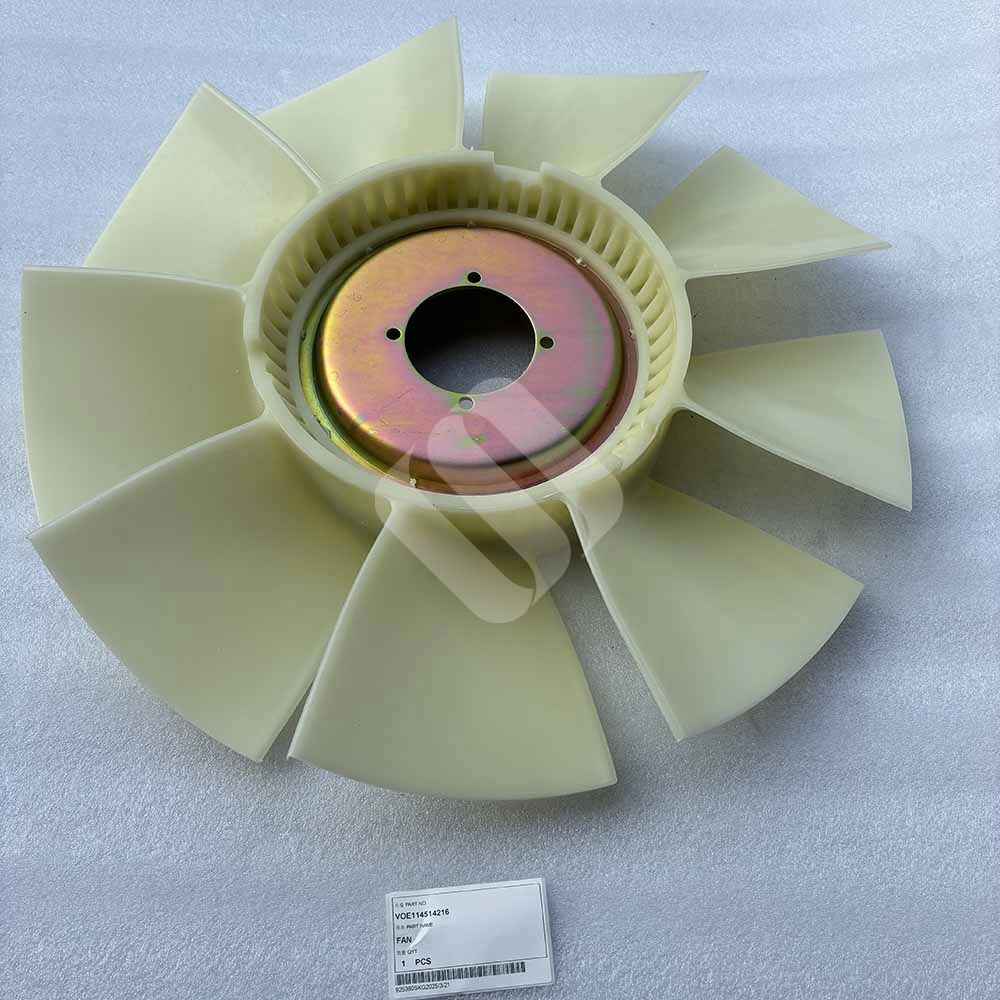

Construction Spare Parts VOE14514216 FAN for Volvo Excavators EC135B EC140B

The Construction Spare Parts VOE14514216 FAN is a premium cooling system component tailored for Volvo EC135B/EC140B excavators. It delivers consistent high-volume airflow to regulate engine and hydraulic system temperatures, prevents overheating, integrates seamlessly with the equipment’s cooling system, and maintains reliable performance in harsh construction environments.

Key Features

· Custom-engineered for perfect compatibility with Volvo EC135B/EC140B excavators

· Aerodynamically optimized blade design for maximum airflow efficiency and energy savings

· Precision-balanced rotation to minimize vibration and reduce wear on adjacent components

· Durable, corrosion-resistant structure to withstand dust, moisture, and extreme temperature fluctuations

· Strict adherence to Volvo OEM specifications for consistent functionality and seamless fit

Compatible Models

· Volvo Construction Equipment Excavators: EC135B, EC140B

Construction Spare Parts VOE14637364 FAN for Volvo Excavators EC300D

The Construction Spare Parts VOE14637364 FAN is a premium cooling system component tailored for Volvo EC300D excavators. It delivers consistent, high-volume airflow to regulate engine and hydraulic system temperatures, prevents overheating, integrates seamlessly with the equipment’s cooling system, and maintains reliability in harsh construction environments.

Key Features

· Custom-engineered for perfect compatibility with Volvo EC300D excavators

· Aerodynamically optimized blade design for maximum airflow efficiency

· Balanced rotation to minimize vibration and reduce wear on related components

· Durable, corrosion-resistant materials to withstand dust, moisture, and extreme temperatures

· Strict adherence to Volvo OEM specifications for consistent functionality and fit

Compatible Models

· Volvo Construction Equipment Excavators: EC300D

Sparkling Machinery Co.,Ltd

foreverlucia1