Reducing Downtime: Reliable Hydraulic Hose for EC480D Series

- Reducing Downtime: Reliable Hydraulic Hose for EC480D Series

- Why choosing the right hydraulic hose matters for EC480D and EC480DHR

- About the product: Hydraulic Hose For Volvo Construction Equipment models EC480D EC480DHR VOE14578951 14578951

- How hydraulic hose failures create downtime and hidden costs

- Technical specifications and direct-fit compatibility

- Pressure ratings, impulse resistance and material science

- Installation best practices for reducing downtime

- Preventive maintenance checklist to detect hose wear early

- Field performance: EC480D use cases and hydraulic demands

- Cost-benefit comparison: OEM VOE14578951 vs common aftermarket alternatives

- Real-world ROI: why spending more on correct hose matters

- Why SPARKLING MACHINERY should be your supplier for VOE14578951 hydraulic hose

- Ordering, lead times, warranty and support for Hydraulic Hose For Volvo Construction Equipment models EC480D EC480DHR VOE14578951 14578951

- FAQ — Frequently Asked Questions

- Contact us / View product

- Authoritative references and further reading

Reducing Downtime: Reliable Hydraulic Hose for EC480D Series

Why choosing the right hydraulic hose matters for EC480D and EC480DHR

Downtime on large excavators like the Volvo EC480D series hits productivity and your bottom line immediately. A leaking or failed hydraulic hose can halt a 50-ton machine, cause environmental contamination, create safety hazards, and lead to secondary component damage. Selecting a high-quality hydraulic hose designed for the hydraulic pressures and working environments of the EC480D/EC480DHR is one of the most effective ways to reduce unplanned downtime and maintain peak performance.

About the product: Hydraulic Hose For Volvo Construction Equipment models EC480D EC480DHR VOE14578951 14578951

Ensure peak hydraulic efficiency for your heavy-duty fleet with the VOE14578951 Hydraulic Hose, exclusively supplied by SPARKLING MACHINERY. This High Quality hose is specifically engineered for high-pressure applications in Volvo’s large-scale excavators and pipelayers.

Fabricated from multi-layered reinforced synthetic rubber, our VOE14578951 hose is built to withstand extreme pressure fluctuations and abrasive environments. Whether your EC480D is working in a quarry or your EC480DHR is engaged in high-reach demolition, this hose ensures zero-leakage performance and long-term reliability.

Key Specifications:

OEM Part Number: VOE14578951 / 14578951.

Enhanced Durability: Resistant to oil, weather, and high-impulse hydraulic cycles.

Exact Fitment: Designed as a direct replacement for Volvo EC480D series, ensuring easy installation.

High Pressure Rated: Engineered for the demanding hydraulic demands of 50-ton class machinery.

Supported Equipment:

Excavators: EC480D, EC480DHR (High Reach Demolition).

Pipelayers: PL4809D.

How hydraulic hose failures create downtime and hidden costs

Hydraulic hose failures are rarely isolated events. A burst hose can spray hydraulic fluid, requiring immediate shutdown for safety. The costs include the hose replacement itself, lost operator hours, potential cleanup, repair of any contaminated components, and possible fines for environmental spills. Indirect costs include schedule delays, overtime for recovery, and reduced client confidence. Using the correct VOE14578951 hydraulic hose for Volvo EC480D models reduces these risks significantly.

Technical specifications and direct-fit compatibility

When specifying a hydraulic hose for large excavators, compatibility with OEM part numbers and pressure ratings is essential. The VOE14578951 (14578951) is manufactured to meet Volvo’s fitment and performance requirements for EC480D and EC480DHR machines. Below is a concise specification table to help technicians and procurement teams compare critical attributes at a glance.

| Attribute | VOE14578951 (14578951) | Why it matters |

|---|---|---|

| OEM Part Number | VOE14578951 / 14578951 | Assures exact fit and compatibility with Volvo EC480D hydraulic connections |

| Construction | Multi-layered reinforced synthetic rubber | Resists abrasion and provides structural strength under pressure cycles |

| Pressure Rating | High-pressure rated for 50-ton class machinery | Handles peak pressures and impulse cycles without failure |

| Fluid Compatibility | Hydraulic oil, mineral oil-based fluids | Prevents swelling and degradation when in contact with common hydraulic fluids |

| Environmental Resistance | Oil, weather, UV-resistant | Extends service life in outdoor heavy equipment applications |

| Applications | Excavators EC480D / EC480DHR, Pipelayers PL4809D | Engineered for large-scale construction and demolition use-cases |

Pressure ratings, impulse resistance and material science

Large excavators generate high static and dynamic hydraulic pressures. The VOE14578951 hydraulic hose uses multiple reinforcement layers (typically braided or spiral steel wire layers) embedded in synthetic rubber to resist burst and impulse fatigue. Impulse resistance—the ability to withstand rapid pressure spikes—is critical in excavator boom and stick circuits where directional control valves and pump surges are common. Using hoses rated for the correct impulse cycles reduces micro-fatigue and premature failure.

Installation best practices for reducing downtime

Even the best hydraulic hose will fail prematurely if installed incorrectly. Follow these practical steps to ensure long service life and minimize downtime:

- Confirm OEM part number (VOE14578951) and inspect fittings for damage.

- Use correct crimp or flange fittings matched to the hose specification.

- Avoid sharp bends and maintain proper bend radius to prevent kinking.

- Use routing clamps and protective sleeves in high-abrasion areas.

- Torque connections to manufacturer specifications to avoid leaks or thread damage.

- Bleed the system and run a controlled pressure test before returning machine to service.

Preventive maintenance checklist to detect hose wear early

Regular inspection prevents small issues from turning into full shutdowns. A simple preventive maintenance (PM) schedule can dramatically reduce unplanned downtime.

- Daily visual checks: look for abrasions, chafing, bulges, or oil seepage.

- Weekly touch test: feel for soft spots or heat concentration along hose length.

- Monthly torque check on fittings and replace protective sleeves showing wear.

- Quarterly: document hose condition and compare against baseline photos to spot deterioration.

- Replace per OEM life guidance or immediately if contamination, deep cuts, or bulging are found.

Field performance: EC480D use cases and hydraulic demands

EC480D and EC480DHR machines operate in heavy-duty environments—quarries, demolition sites, and pipelaying—which expose hoses to rock impact, extreme temperatures, and frequent pressure fluctuations. The VOE14578951 hydraulic hose is engineered for such environments, with abrasion-resistant covers and reinforcement that maintain integrity under repeated flexing and impact. Where applicable, adding external abrasion guards or spiral wraps can further protect hose runs in high-wear areas.

Cost-benefit comparison: OEM VOE14578951 vs common aftermarket alternatives

Fleet managers must weigh upfront part cost against total lifecycle cost (downtime risk, replacement frequency, warranty coverage). The table below summarizes typical differences.

| Factor | OEM VOE14578951 | Typical Aftermarket Hose |

|---|---|---|

| Initial cost | Higher | Lower |

| Fit and compatibility | Exact OE fit | May require adaptation or lead to misfit |

| Impulse and burst protection | Engineered to match machine demand | Variable—depends on manufacturer |

| Warranty and support | OEM-backed supply chain and support | Varies; often limited |

| Lifecycle cost | Lower overall due to fewer failures | Higher risk of repeated replacements and downtime |

Real-world ROI: why spending more on correct hose matters

Minimizing unplanned downtime yields immediate returns: more operating hours, fewer emergency repair costs, and improved project timelines. For heavy equipment where an hour of downtime can cost hundreds to thousands of dollars, selecting the VOE14578951 hydraulic hose as an OEM direct replacement is often justified by reduced failure rates and extended service intervals.

Why SPARKLING MACHINERY should be your supplier for VOE14578951 hydraulic hose

SPARKLING MACHINERY supplies the VOE14578951 hydraulic hose built to OEM fit and performance criteria. The core advantages our customers report include:

- Guaranteed OEM part number supply and traceability

- Quality inspection and packaging to prevent transport damage

- Technical support for fitment and installation queries

- Competitive lead times and global logistics for fleet operators

These advantages translate to faster repairs, fewer repeat failures, and reduced administrative overhead when managing parts inventories.

Ordering, lead times, warranty and support for Hydraulic Hose For Volvo Construction Equipment models EC480D EC480DHR VOE14578951 14578951

SPARKLING MACHINERY offers global shipping and parts verification for VOE14578951. Typical stock lead times depend on region; contact our parts team for real-time availability. All hoses come with manufacturer-backed quality assurance. For fleet procurement, we provide batch documentation and assistance with parts catalog cross-referencing to ensure you order the correct hoses for EC480D, EC480DHR, and PL4809D applications.

FAQ — Frequently Asked Questions

Q: Is VOE14578951 an exact replacement for Volvo EC480D hydraulic lines?

A: Yes. VOE14578951 (14578951) is the OEM part number specified for hydraulic hose replacement in EC480D and EC480DHR applications and is designed for direct fitment.

Q: Can I use a lower-cost aftermarket hydraulic hose?

A: While lower-cost hoses can reduce initial spending, they often lack the impulse resistance and materials required for 50-ton class machinery. This can lead to increased downtime and higher lifecycle costs. OEM VOE14578951 minimizes that risk.

Q: What are the common signs a hydraulic hose needs replacement?

A: Look for visible wear (abraded cover, cuts), bulging, leaking fluid, soft spots, loose fittings, and unusual heat buildup. Any of these signs should prompt immediate inspection and likely replacement.

Q: How should I route hoses on EC480D to prevent damage?

A: Maintain manufacturer-specified bend radii, secure hoses with clamps, avoid contact with sharp edges, use protective sleeves in abrasion-prone areas, and route away from heat sources such as exhausts.

Q: What maintenance schedule is recommended for hydraulic hoses?

A: Daily visual checks, weekly touch tests, monthly torque and sleeve inspections, and quarterly condition audits are a practical baseline. Replace hoses immediately upon detection of significant wear.

Contact us / View product

Reduce downtime and protect your EC480D fleet by choosing the VOE14578951 hydraulic hose. For pricing, availability, or technical assistance, contact SPARKLING MACHINERY parts team or visit our product page to request a quote and lead time. Our specialists can verify fitment, ship replacement hoses quickly, and provide guidance on installation and preventive maintenance.

Authoritative references and further reading

For technical context and standards related to hydraulic hoses and heavy equipment hydraulics, consult the following authoritative sources:

- Hydraulics — Wikipedia: https://en.wikipedia.org/wiki/Hydraulics

- SAE International — J517 Hydraulic Hose Standard (overview): https://www.sae.org/standards/content/j517_201601/

- Parker Hannifin — Hydraulic Hose Product & Selection Guides: https://www.parker.com/portal/site/PARKER/menuitem.c17ed996926f82e0fb7ce7421417e39a/?vgnextoid=f6f3af6e06c5d210VgnVCM1000000308a8c0RCRD&vgnextfmt=default

- Eaton Hydraulics — Hose & Fittings Information: https://www.eaton.com/us/en-us/products/hose-fitting/hose.

- Volvo Construction Equipment — Official Site (parts & service): https://www.volvoce.com

Choosing the right hydraulic hose and supplier is a practical investment in uptime. The VOE14578951 hydraulic hose supplied by SPARKLING MACHINERY provides OEM compatibility, materials engineered for tough environments, and the support services needed to keep EC480D-class machines working reliably.

What are the application scenarios of Excavator Electrical Parts?

Signs Your Excavator's Hydraulic System Needs Attention

OEM vs Aftermarket: Hydraulic Hose Choices for Volvo EC480D

What are the application scenarios of Excavator Hydraulic Pump?

faq

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

VOE14562193 24V Excavator Switch – Compatible with Volvo EC140B EC290C EC460B EC55C EC60E

SPARKLING MACHINERY NEW EC140B EC140C EC160B EC160C EC180B EC180C VOE14562193 Switch is a dedicated, high-reliability electrical control component exclusively engineered for VOLVO EC140B/EC140C, EC160B/EC160C, and EC180B/EC180C crawler excavators—versatile mid-sized equipment widely used in construction, municipal engineering, and light mining projects. As a core interface for the excavator’s electrical system, it enables precise activation and control of key functions (e.g., auxiliary lights, hydraulic auxiliary systems, or safety alarms), ensuring responsive operation and operator safety during high-intensity tasks. This function is vital for maintaining smooth workflow coordination, preventing accidental function activation, and avoiding operational disruptions caused by faulty electrical controls during tasks like trench digging, material loading, or site grading.

Engineered to meet VOLVO’s original equipment (OEM) standards and marked with the genuine part number VOE14562193, the switch withstands harsh working conditions: extreme temperature fluctuations (-30°C to 70°C), water and dust ingress (IP65 protection rating), and continuous vibration from heavy-duty use. It resists electrical interference and mechanical wear, providing long-lasting control reliability for the six VOLVO crawler excavator models. Backed by strict performance verification, it guarantees seamless compatibility and safe operation for daily excavator tasks.

Volvo Excavator Control Unit 60100000 – Spare Part for EC140C, EC160C, EC170D, EC180C

SPARKLING MACHINERY NEW EC210 EC210B EC210BLC 60100000 Controller C is a dedicated, high-precision electronic control unit exclusively engineered for VOLVO EC210, EC210B, and EC210BLC crawler excavators—versatile mid-sized equipment widely used in construction, municipal engineering, and light mining projects. As the “brain” of the excavator’s operational system, it processes real-time data from sensors (engine speed, hydraulic pressure, operator inputs) to coordinate the work of core mechanisms (boom, arm, bucket) and auxiliary systems, ensuring smooth, synchronized operation during tasks like trench digging, material loading, and site grading. This function is vital for preventing operational lags, optimizing energy efficiency, and avoiding unplanned downtime caused by system miscommunication.

Engineered to meet VOLVO’s original equipment (OEM) standards and marked with the part number 60100000, the Controller C withstands harsh working conditions: extreme temperature fluctuations (-30°C to 70°C), electromagnetic interference, and continuous vibration from heavy-duty use. It maintains stable data transmission and reliable control performance, providing long-lasting operational support for the three VOLVO excavator models. Backed by strict performance verification, it guarantees seamless compatibility and safe operation for daily excavator tasks.

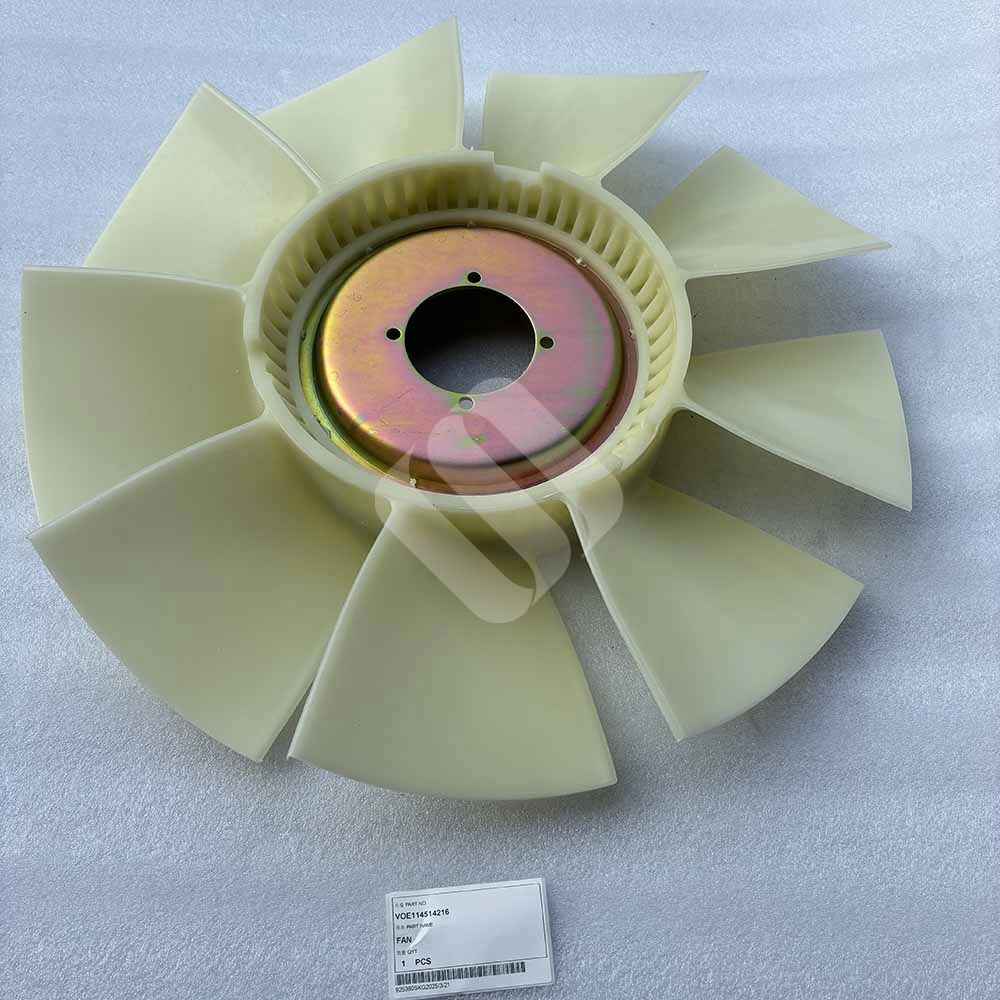

Construction Spare Parts VOE14514216 FAN for Volvo Excavators EC135B EC140B

The Construction Spare Parts VOE14514216 FAN is a premium cooling system component tailored for Volvo EC135B/EC140B excavators. It delivers consistent high-volume airflow to regulate engine and hydraulic system temperatures, prevents overheating, integrates seamlessly with the equipment’s cooling system, and maintains reliable performance in harsh construction environments.

Key Features

· Custom-engineered for perfect compatibility with Volvo EC135B/EC140B excavators

· Aerodynamically optimized blade design for maximum airflow efficiency and energy savings

· Precision-balanced rotation to minimize vibration and reduce wear on adjacent components

· Durable, corrosion-resistant structure to withstand dust, moisture, and extreme temperature fluctuations

· Strict adherence to Volvo OEM specifications for consistent functionality and seamless fit

Compatible Models

· Volvo Construction Equipment Excavators: EC135B, EC140B

Construction Spare Parts VOE14637364 FAN for Volvo Excavators EC300D

The Construction Spare Parts VOE14637364 FAN is a premium cooling system component tailored for Volvo EC300D excavators. It delivers consistent, high-volume airflow to regulate engine and hydraulic system temperatures, prevents overheating, integrates seamlessly with the equipment’s cooling system, and maintains reliability in harsh construction environments.

Key Features

· Custom-engineered for perfect compatibility with Volvo EC300D excavators

· Aerodynamically optimized blade design for maximum airflow efficiency

· Balanced rotation to minimize vibration and reduce wear on related components

· Durable, corrosion-resistant materials to withstand dust, moisture, and extreme temperatures

· Strict adherence to Volvo OEM specifications for consistent functionality and fit

Compatible Models

· Volvo Construction Equipment Excavators: EC300D

Sparkling Machinery Co.,Ltd

foreverlucia1