The B2B Buyer’s Guide to Excavator Hydraulic Motors

- Introduction: The B2B Buyer’s Guide to Excavator Hydraulic Motors

- Why this guide matters for procurement and fleet managers

- What Excavator Hydraulic Motors Do and Why They Matter

- Core function: power conversion and precise control

- Types of Excavator Hydraulic Motors: Choosing by Application

- Axial piston motors (swashplate): high performance for heavy duty

- Gear and gerotor motors: cost-effective and compact

- Key Specifications Buyers Must Check Before Purchase

- Pressure rating and system flow compatibility

- Displacement, torque, and speed: the performance triangle

- Mounting, shaft interfaces, and physical compatibility

- Performance, Efficiency & Reliability Considerations

- Efficiency metrics and heat management

- Durability, seals, and materials for harsh environments

- Installation & Maintenance Best Practices to Maximize Uptime

- Filtration, fluid care, and contamination control

- Installation, commissioning, and correct handling

- Sourcing Strategy for B2B Buyers: How to Choose a Supplier

- OEM vs aftermarket: what's best for your fleet

- Supplier checklist: certifications, testing, service and lead times

- Cost of Ownership & ROI Considerations for Procurement

- Assessing lifecycle costs instead of purchase price

- Why Choose SPARKLING MACHINERY for Excavator Hydraulic Motors

- Proven capability: quality, compatibility, and global support

- How to Evaluate and Test Motors Before Full Deployment

- Run-in testing, field trials, and pilot programs

- Trends & Market Signals B2B Buyers Should Watch

- Electrification, telematics, and material innovations

- Conclusion: A Practical Buying Checklist

- Final action items for procurement teams

- Frequently Asked Questions

Introduction: The B2B Buyer’s Guide to Excavator Hydraulic Motors

Why this guide matters for procurement and fleet managers

Purchasing Excavator Hydraulic Motors is a strategic decision for construction, mining, and rental fleets. These components determine machine performance, fuel efficiency, uptime, and total cost of ownership. This guide translates technical details into actionable criteria for B2B buyers—helping you choose motors that match application demands, reduce downtime, and optimize lifecycle costs.

What Excavator Hydraulic Motors Do and Why They Matter

Core function: power conversion and precise control

Excavator Hydraulic Motors convert pressurized hydraulic fluid into mechanical rotation to drive slewing, travel, or auxiliary functions. Their selection affects machine speed, tractive force, and control sensitivity. For buyers, motors are not just parts — they are performance enablers: the right motor improves cycle times, reduces operator fatigue, and lowers fuel consumption by matching torque/speed characteristics to the task.

Types of Excavator Hydraulic Motors: Choosing by Application

Axial piston motors (swashplate): high performance for heavy duty

Axial piston motors are common in modern excavators because they deliver high power density, high efficiency, and adjustable displacement options. They are ideal for demanding travel and swing applications where continuous high pressure (often up to several hundred bar in heavy-duty systems) and precise speed control are required. For B2B buyers focused on productivity, axial piston motors are typically the first choice.

Gear and gerotor motors: cost-effective and compact

Gear and gerotor (internal gear) motors are simpler and usually have lower manufacturing costs. They are suitable for lower-speed, lower-torque auxiliary functions or compact machines where budget and space are priorities. Buyers looking for affordable replacements for less demanding applications often select high-quality gear motors from reputable aftermarket suppliers.

Key Specifications Buyers Must Check Before Purchase

Pressure rating and system flow compatibility

Match motor pressure rating with your excavator’s hydraulic system. Heavy excavators frequently operate at peak system pressures up to around 300–350 bar in high-demand circuits; select motors rated above the system’s maximum working pressure with a safety margin to ensure reliability. Also verify required flow rates and that pump flow and motor displacement yield targeted speed and torque.

Displacement, torque, and speed: the performance triangle

Displacement (volume per revolution), torque output, and rotational speed are interrelated. Higher displacement produces higher torque at a given pressure but reduces maximum speed at a given flow. For digging and travel functions where torque is critical, prioritize motors with higher displacement or those that support high-pressure operation. For swing motors, prioritize smooth control and braking performance.

Mounting, shaft interfaces, and physical compatibility

Ensure the motor’s mounting flange, bolt pattern, shaft type (splined, keyed, or tapered), and overall dimensions match the excavator’s gearbox or mounting bracket. Mechanical compatibility avoids costly retrofitting and long lead times. When buying in volume, standardize motors across your fleet to streamline spare part stocking and reduce inventory costs.

Performance, Efficiency & Reliability Considerations

Efficiency metrics and heat management

Hydraulic motor efficiency impacts fuel consumption and heat generation. Look for volumetric and mechanical efficiency ratings from manufacturers; higher-efficiency units reduce wasted energy and heat load on the hydraulic system. Proper heat management (coolers, correct fluid selection, and system design) prolongs motor life and maintains consistent performance under continuous loads.

Durability, seals, and materials for harsh environments

Excavators work in abrasive, dusty, and wet environments. Motors with robust bearings, hardened gears, and advanced seal designs resist contamination and water ingress. For applications involving high shock loads or continuous operation, choose motors with proven test data, long maintenance intervals, and field-proven track records. Insist on test reports and lifecycle data from your supplier.

Installation & Maintenance Best Practices to Maximize Uptime

Filtration, fluid care, and contamination control

Contamination is the leading cause of hydraulic motor failure. Use OEM-recommended hydraulic fluids, maintain proper viscosity and additive balance, and employ filtration that meets your system’s cleanliness target. Regularly monitor fluid condition and particle counts; proactive fluid analysis can prevent premature wear and catastrophic failure.

Installation, commissioning, and correct handling

Proper installation is critical: align shafts correctly, use correct torque on mounting bolts, and follow manufacturer break-in procedures. During commissioning check for correct flow direction, pressure limits, and leak-free fittings. Train technicians in safe handling and provide clear documentation; poor installation practices are common sources of warranty claims.

Sourcing Strategy for B2B Buyers: How to Choose a Supplier

OEM vs aftermarket: what's best for your fleet

OEM parts often guarantee direct fit and manufacturer support but can carry a High Quality. High-quality aftermarket suppliers can deliver equivalent performance at lower cost and often provide customization and faster lead times. For B2B buyers, the decision should be based on application criticality, total cost of ownership, warranty coverage, and supplier reliability.

Supplier checklist: certifications, testing, service and lead times

When evaluating suppliers, insist on ISO 9001 or equivalent quality systems, documented testing (pressure, torque, endurance), and traceability of components. Check warranty terms, availability of spare parts, technical support, and global logistics capabilities. Shorter lead times and a responsive service network reduce downtime risk—critical for rental and large fleet operators.

Cost of Ownership & ROI Considerations for Procurement

Assessing lifecycle costs instead of purchase price

Compare initial cost with expected service life, maintenance intervals, efficiency gains, and downtime costs. A slightly more expensive motor with higher efficiency and longer life can deliver lower total ownership costs. Include shipping, installation, spare parts, and potential machine downtime in your ROI calculations.

Why Choose SPARKLING MACHINERY for Excavator Hydraulic Motors

Proven capability: quality, compatibility, and global support

Founded in 2013, SPARKLING MACHINERY focuses on high-quality excavator parts and a commitment to stability, precision, and perseverance. We offer hydraulic components compatible with major brands such as Caterpillar, Komatsu, Hitachi, and Volvo. Through strict manufacturing and quality control, SPARKLING MACHINERY ensures parts operate reliably under diverse working conditions. We provide customization, technical support, and global after-sales service—helping buyers reduce cost while maintaining performance.

How to Evaluate and Test Motors Before Full Deployment

Run-in testing, field trials, and pilot programs

Before rolling out motors across your fleet, run bench and field tests. Bench testing validates pressure, leakage, and torque; short field trials under real working conditions reveal heat build-up, control feel, and installation issues. For large purchases, negotiate pilot orders and acceptance criteria to de-risk large deployments.

Trends & Market Signals B2B Buyers Should Watch

Electrification, telematics, and material innovations

Industry trends such as hybrid and electric drivetrains are influencing hydraulic system design. Telematics and condition monitoring help predict failures and optimize maintenance. Material advances and improved sealing technologies extend motor life. Buyers should ask suppliers about compatibility with future system upgrades and readiness for digital condition monitoring.

Conclusion: A Practical Buying Checklist

Final action items for procurement teams

Use this checklist when evaluating Excavator Hydraulic Motors: 1) Confirm pressure and flow compatibility; 2) Match displacement, torque and speed to application; 3) Verify mechanical fit (mounting, shaft); 4) Review efficiency and expected lifecycle; 5) Inspect supplier certifications and testing data; 6) Ask about warranty, spare parts, and technical support; 7) Run pilot tests before fleet-wide adoption. Following these steps will reduce downtime, control costs, and ensure peak machine performance.

SPARKLING MACHINERY stands ready to support B2B buyers with proven hydraulic motors, OEM compatibility, customizable solutions, and global logistics. Contact us for application-specific recommendations, sample testing, and bulk procurement options tailored to your fleet.

Note on data and reliability: This guide is based on industry best practices, common hydraulic system specifications, and manufacturing standards current as of mid-2024. For machine-specific requirements, always consult equipment OEM manuals and conduct application-specific testing.

Frequently Asked Questions

Q: How do I know whether to choose an axial piston motor or a gear motor for my excavator?A: Choose an axial piston motor for high-power, high-pressure applications like main travel and swing where efficiency and control matter. Gear motors are suitable for lower-power auxiliary tasks and compact machines where cost and space are primary considerations.

Q: What is the typical pressure rating I should expect for heavy-duty excavator hydraulic motors?A: Heavy-duty excavator circuits commonly operate up to approximately 300–350 bar (around 4,350–5,075 psi) in some systems. Select motors with ratings above your system’s maximum working pressure and include a safety margin.

Q: How important is hydraulic fluid cleanliness and filtration for motor life?A: Extremely important. Contamination is a leading cause of hydraulic component wear and failure. Maintain correct filtration, monitor fluid condition, and adhere to recommended maintenance intervals to maximize motor life.

Q: Are aftermarket hydraulic motors a safe option compared to OEM parts?A: High-quality aftermarket motors can offer equivalent performance at lower cost. Evaluate suppliers for certifications, testing data, material traceability, warranty, and service capabilities before selecting aftermarket options.

Q: What should be included in a motor pilot test before full-scale purchasing?A: Include bench pressure/leakage tests, short-term field trials under expected loads, heat and efficiency measurements, and installation checks. Define acceptance criteria in advance and validate performance against those metrics.

Q: How can SPARKLING MACHINERY support bulk procurement and aftermarket service?A: SPARKLING MACHINERY provides compatible hydraulic components for major brands, strict quality control, customization options, and global logistics. We offer technical consultation, test reports, and after-sales support to reduce downtime and lifecycle costs.

Q: What documentation should I require from a hydraulic motor supplier?A: Request ISO quality certificates, detailed technical specifications, test reports (pressure, torque, endurance), material traceability, maintenance manuals, and warranty terms.

Q: How often should hydraulic motors be inspected and serviced?A: Inspection frequency depends on application severity, but routine checks on fluid condition, leakage, and mounting every 250–1,000 operating hours are common. Follow manufacturer recommendations and adapt frequency based on operating conditions.

Supply Chain Risk: Sourcing Pressure Sensors for Hitachi Fleets

Guide to R170W7 Excavator Parts and Key Components

The B2B Buyer’s Guide to Hydraulic Cylinders for Excavators

Maintenance Impact: Pressure Sensor Failure on SR2000G Hydraulics

faq

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

VOE14562193 24V Excavator Switch – Compatible with Volvo EC140B EC290C EC460B EC55C EC60E

SPARKLING MACHINERY NEW EC140B EC140C EC160B EC160C EC180B EC180C VOE14562193 Switch is a dedicated, high-reliability electrical control component exclusively engineered for VOLVO EC140B/EC140C, EC160B/EC160C, and EC180B/EC180C crawler excavators—versatile mid-sized equipment widely used in construction, municipal engineering, and light mining projects. As a core interface for the excavator’s electrical system, it enables precise activation and control of key functions (e.g., auxiliary lights, hydraulic auxiliary systems, or safety alarms), ensuring responsive operation and operator safety during high-intensity tasks. This function is vital for maintaining smooth workflow coordination, preventing accidental function activation, and avoiding operational disruptions caused by faulty electrical controls during tasks like trench digging, material loading, or site grading.

Engineered to meet VOLVO’s original equipment (OEM) standards and marked with the genuine part number VOE14562193, the switch withstands harsh working conditions: extreme temperature fluctuations (-30°C to 70°C), water and dust ingress (IP65 protection rating), and continuous vibration from heavy-duty use. It resists electrical interference and mechanical wear, providing long-lasting control reliability for the six VOLVO crawler excavator models. Backed by strict performance verification, it guarantees seamless compatibility and safe operation for daily excavator tasks.

Volvo Excavator Control Unit 60100000 – Spare Part for EC140C, EC160C, EC170D, EC180C

SPARKLING MACHINERY NEW EC210 EC210B EC210BLC 60100000 Controller C is a dedicated, high-precision electronic control unit exclusively engineered for VOLVO EC210, EC210B, and EC210BLC crawler excavators—versatile mid-sized equipment widely used in construction, municipal engineering, and light mining projects. As the “brain” of the excavator’s operational system, it processes real-time data from sensors (engine speed, hydraulic pressure, operator inputs) to coordinate the work of core mechanisms (boom, arm, bucket) and auxiliary systems, ensuring smooth, synchronized operation during tasks like trench digging, material loading, and site grading. This function is vital for preventing operational lags, optimizing energy efficiency, and avoiding unplanned downtime caused by system miscommunication.

Engineered to meet VOLVO’s original equipment (OEM) standards and marked with the part number 60100000, the Controller C withstands harsh working conditions: extreme temperature fluctuations (-30°C to 70°C), electromagnetic interference, and continuous vibration from heavy-duty use. It maintains stable data transmission and reliable control performance, providing long-lasting operational support for the three VOLVO excavator models. Backed by strict performance verification, it guarantees seamless compatibility and safe operation for daily excavator tasks.

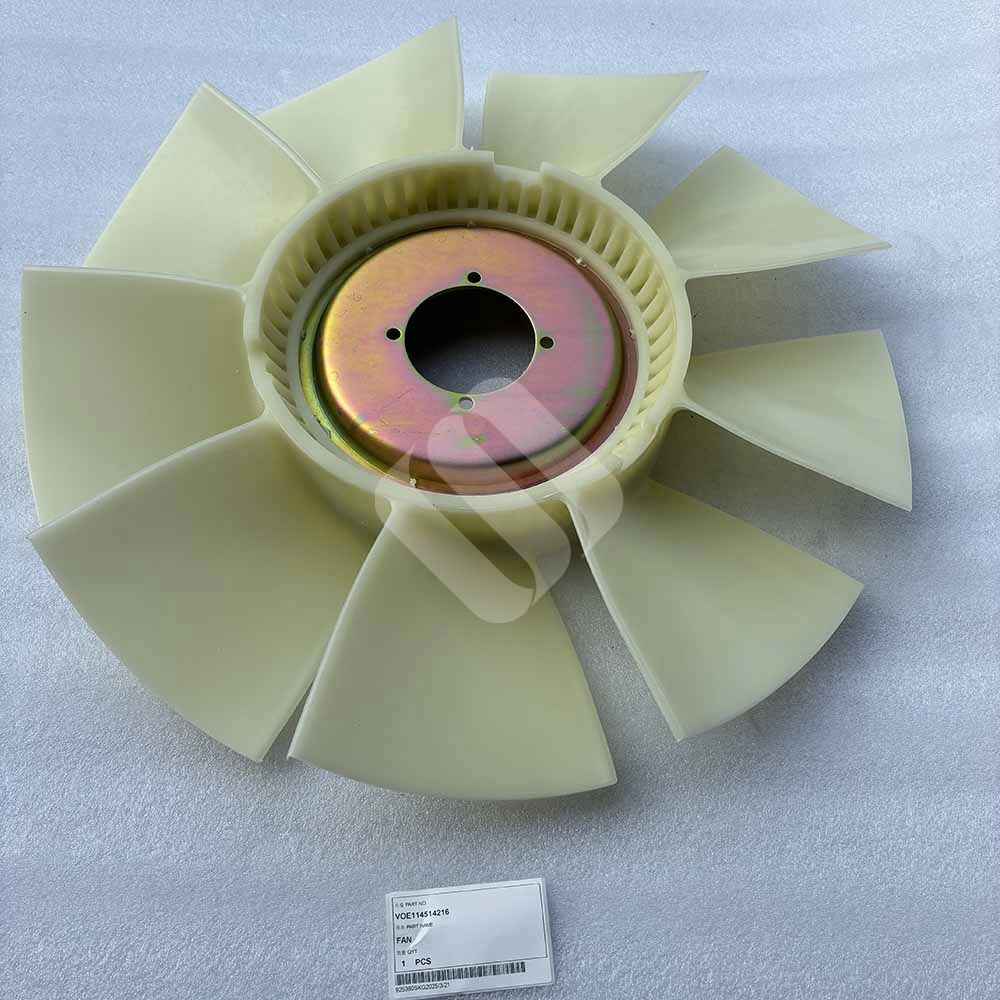

Construction Spare Parts VOE14514216 FAN for Volvo Excavators EC135B EC140B

The Construction Spare Parts VOE14514216 FAN is a premium cooling system component tailored for Volvo EC135B/EC140B excavators. It delivers consistent high-volume airflow to regulate engine and hydraulic system temperatures, prevents overheating, integrates seamlessly with the equipment’s cooling system, and maintains reliable performance in harsh construction environments.

Key Features

· Custom-engineered for perfect compatibility with Volvo EC135B/EC140B excavators

· Aerodynamically optimized blade design for maximum airflow efficiency and energy savings

· Precision-balanced rotation to minimize vibration and reduce wear on adjacent components

· Durable, corrosion-resistant structure to withstand dust, moisture, and extreme temperature fluctuations

· Strict adherence to Volvo OEM specifications for consistent functionality and seamless fit

Compatible Models

· Volvo Construction Equipment Excavators: EC135B, EC140B

Construction Spare Parts VOE14637364 FAN for Volvo Excavators EC300D

The Construction Spare Parts VOE14637364 FAN is a premium cooling system component tailored for Volvo EC300D excavators. It delivers consistent, high-volume airflow to regulate engine and hydraulic system temperatures, prevents overheating, integrates seamlessly with the equipment’s cooling system, and maintains reliability in harsh construction environments.

Key Features

· Custom-engineered for perfect compatibility with Volvo EC300D excavators

· Aerodynamically optimized blade design for maximum airflow efficiency

· Balanced rotation to minimize vibration and reduce wear on related components

· Durable, corrosion-resistant materials to withstand dust, moisture, and extreme temperatures

· Strict adherence to Volvo OEM specifications for consistent functionality and fit

Compatible Models

· Volvo Construction Equipment Excavators: EC300D

Sparkling Machinery Co.,Ltd

foreverlucia1