The B2B Buyer’s Guide to Excavator Parts

- The B2B Buyer’s Guide to Excavator Parts

- Understanding the Core Excavator Parts

- Why Quality Matters in Excavator Parts

- How to Evaluate Excavator Parts Suppliers

- Cost Efficiency and Competitive Pricing

- Customization and Technical Support

- Global Network and Logistics

- Conclusion: Making Informed Purchasing Decisions

- Commonly Asked Questions

The B2B Buyer’s Guide to Excavator Parts

Excavator parts are the backbone of heavy machinery operations that keep construction, mining, and infrastructure projects moving efficiently. For B2B buyers, finding the right excavator parts supplier is essential to ensure equipment reliability, reduce downtime, and control operational costs. This guide from SPARKLING MACHINERY—an industry-leading provider since 2013—explains what to look for when sourcing excavator parts, how to evaluate suppliers, and how to optimize your procurement process.

Understanding the Core Excavator Parts

Before making any purchasing decisions, B2B buyers must familiarize themselves with the main components needed for excavator maintenance and repair. Excavator parts typically include hydraulic components, undercarriage systems, engine components, electrical systems, cabs, mini excavators, and various accessories. High-quality parts ensure smooth operation compatible with leading machinery brands such as Caterpillar, Komatsu, Hitachi, and Volvo.

Why Quality Matters in Excavator Parts

Purchasing low-quality or incompatible excavator parts can cause frequent breakdowns, increased maintenance costs, and shortened machine lifespan. According to industry data, equipment failures can lead to up to 20% loss in productivity. Reliable parts suppliers like SPARKLING MACHINERY maintain strict quality control standards, ensuring durability and precise fit, which helps minimize costly downtime for your operations.

How to Evaluate Excavator Parts Suppliers

Choosing the right supplier requires attention to more than just pricing. Key factors include product range, compatibility with various excavator brands, manufacturing standards, and after-sales support. SPARKLING MACHINERY distinguishes itself with customized solutions, thorough technical consultation, and a global sales network to provide continuous service. B2B buyers should seek suppliers offering warranties and transparent quality certifications to guarantee product reliability.

Cost Efficiency and Competitive Pricing

While quality is paramount, cost efficiency also drives buying decisions in the excavator parts market. The right supplier strikes a balance between price and quality, helping businesses reduce operational expenses without sacrificing performance. SPARKLING MACHINERY’s commitment to altruism and innovation enables it to provide competitive pricing and tailor-made options that fit varying budget needs.

Customization and Technical Support

Every project or machinery setup has unique requirements. Selecting a supplier that offers tailored parts and solid technical support can greatly improve equipment performance. B2B buyers should consider suppliers who provide in-depth consultation, helping to choose parts that best match operational demands. SPARKLING MACHINERY offers these precise services, ensuring customer specifications are met and maintenance processes are optimized.

Global Network and Logistics

For large-scale operations, timely delivery and reliable logistics are crucial. Suppliers with a robust global network can ensure parts reach customers quickly and safely, minimizing downtime. SPARKLING MACHINERY leverages its worldwide presence to provide prompt shipping and efficient post-sale services, strengthening its position as a trusted partner worldwide.

Conclusion: Making Informed Purchasing Decisions

In the competitive excavator parts marketplace, B2B buyers must combine thorough product knowledge with supplier evaluation to maximize operational success. Prioritizing quality, supplier reliability, customization, and competitive pricing helps achieve long-term cost savings and improved equipment performance. SPARKLING MACHINERY continues to lead the industry by embodying these principles, striving to be the world’s top excavator parts manufacturer.

Commonly Asked Questions

What are the most critical excavator parts to keep in stock?

Hydraulic components, undercarriage parts, and engine components are essential to minimize equipment downtime.

How do I verify the quality of excavator parts?

Look for ISO certifications, compatibility with reputable brands, and supplier warranties to ensure quality.

Can excavator parts be customized?

Yes, many suppliers like SPARKLING MACHINERY offer custom solutions based on your specific machinery and operational needs.

What brands are SPARKLING MACHINERY parts compatible with?

Our parts are compatible with top brands including Caterpillar, Komatsu, Hitachi, and Volvo.

How can I reduce costs when buying excavator parts?

Choose suppliers offering both quality and competitive prices, and consider bulk purchasing or long-term contracts.

Best professional excavator undercarriage parts manufacturers and supplier brands

Made-in-China Excavator Parts: Quality Standards to Check

How to Reduce Downtime with Reliable Pressure Sensors for CP220-3

Wholesale excavator LH control column manufacturer and supplier

faq

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

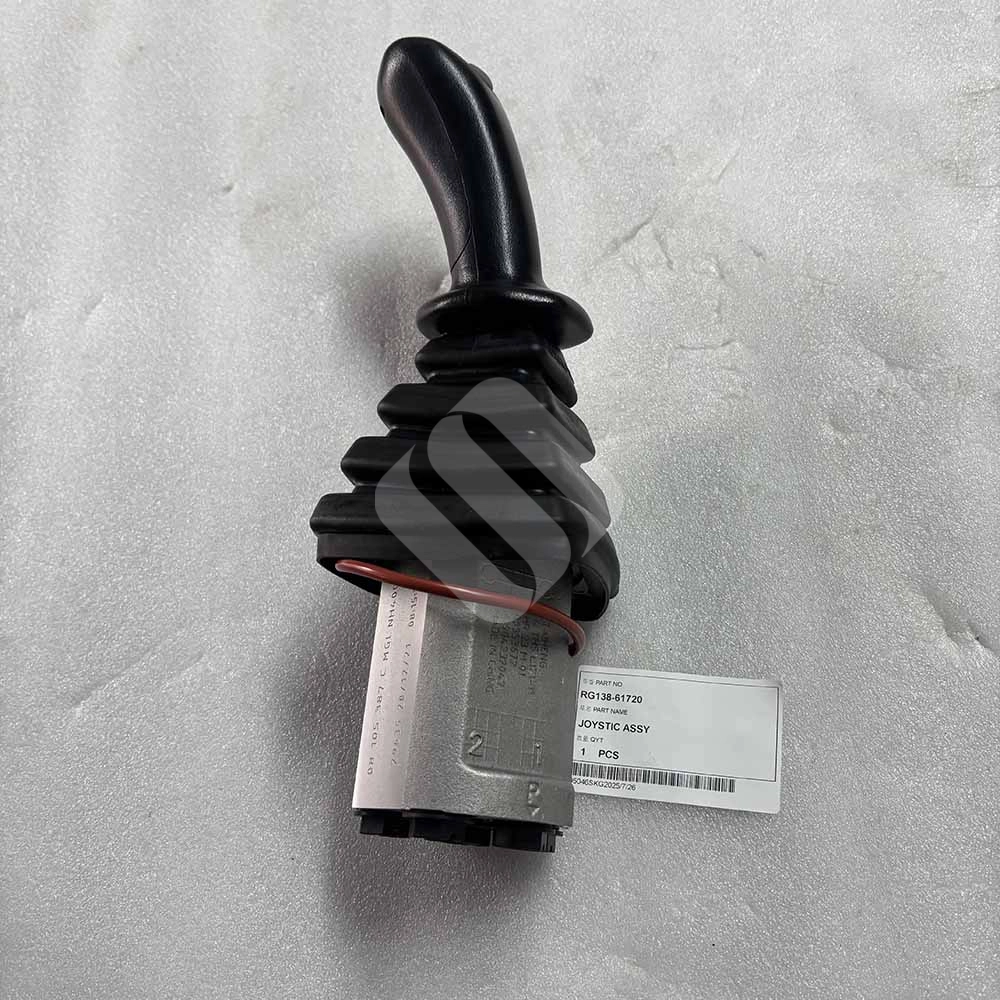

KUBOTA MADE IN CHINA SPARKLING MACHINERY NEW KX016 KX018 RG138-61720 JOYSTICK ASSY

SPARKLING MACHINERY NEW KX016 KX018 RG138-61720 Joystick Assy is a dedicated operational control component exclusively designed for KX016 and KX018 mini excavators—ideal for small-scale construction, landscaping, and indoor renovation tasks. As the core of the excavators’ human-machine interface, it enables precise control of the machine’s working mechanisms (e.g., bucket movement, arm lifting, and body rotation) by translating the operator’s manual inputs into electrical or hydraulic signals. This function is critical for ensuring smooth, accurate operation during delicate tasks like trench digging, material placement, and narrow-space maneuvering, directly enhancing work efficiency and reducing the risk of operational errors that could damage the machine or surrounding structures.

Engineered to match original equipment performance standards, it maintains responsive control and structural durability even under harsh working conditions, including continuous operator use, vibration, and exposure to dust or light moisture. It resists switch failure and handle loosening, avoiding control delays or malfunctions that lead to unplanned downtime. Backed by strict performance verification, it guarantees reliable operational control to support uninterrupted use of KX016/KX018 mini excavators.

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW GF950194 SOLENOID ASSY SPARKLING MACHINERY

SPARKLING MACHINERY NEW GF950194 Solenoid Assy is a core electromagnetic control component for Caterpillar excavators (heavy-duty construction/mining use). It converts electrical signals into mechanical motion to control fluid flow or mechanical switches, ensuring precise system operation.

Meeting Caterpillar OEM standards (GF950194), it resists -30°C to 100°C temps, electromagnetic interference, and wear, ensuring seamless compatibility and long-term reliable control performance.

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 336 330 515-6165 FLY WHEEL SPARKLING MACHINERY

SPARKLING MACHINERY NEW 336 330 515-6165 Fly Wheel is a core powertrain component for Caterpillar 336/330 excavators (heavy-duty construction/mining use). It stores rotational energy, ensures smooth engine operation, and transmits torque to the transmission system.

Meeting Caterpillar OEM standards (515-6165), it resists -30°C to 100°C temps, mechanical stress, and wear, ensuring seamless compatibility and long-term reliable energy transfer performance.

Doosan HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 229-00012A COVER SPARKLING MACHINERY

SPARKLING MACHINERY NEW 229-00012A Cover is a core protective component for Doosan excavators (heavy-duty construction/mining use). It shields critical internal parts (e.g., engine accessories, hydraulic components) from dust, debris, and external impact, maintaining system integrity.

Meeting Doosan OEM standards (229-00012A), it resists -30°C to 100°C temps, corrosion, and mechanical wear, ensuring seamless compatibility and long-term reliable protection for Doosan excavator systems.

Sparkling Machinery Co.,Ltd

foreverlucia1