The Environmental Impact of Excavator Hydraulic Fluids and How to Mitigate It

- Introduction: Why Excavator Hydraulic Fluids Matter for the Environment

- Context and relevance to Excavator Hydraulic Parts

- How Hydraulic Fluids Cause Environmental Harm

- Pathways: leaks, spills, and routine disposal

- Persistent pollution and toxicity

- Fire and air emissions

- Types of Excavator Hydraulic Fluids and Their Environmental Profiles

- Common fluid categories

- Biodegradability standards you should watch

- Practical Table: Comparing Hydraulic Fluid Types

- Quick comparison to guide selection

- Mitigation Strategies: Design, Parts, and Practices

- Choose the right Excavator Hydraulic Parts to reduce leaks

- Specify environmentally preferable hydraulic fluids

- Preventive maintenance and fluid monitoring

- Containment and spill response

- Used Fluid Management and Recycling

- Safe collection and segregation

- Re-refining and proper disposal

- Operational Case: How Much Fluid Are We Talking About?

- Typical hydraulic reservoir volumes and risk scale

- Regulatory and Stakeholder Considerations

- Compliance with environmental regulations

- Client expectations and procurement policies

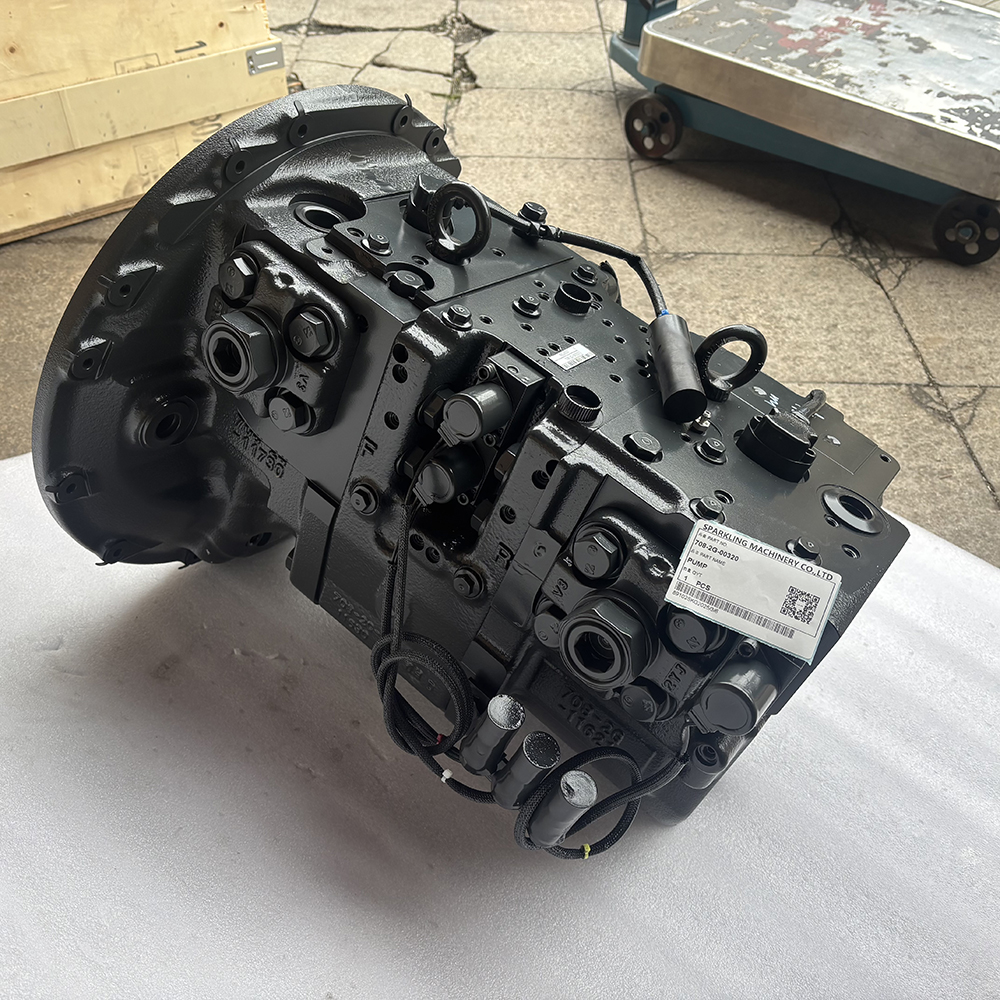

- SPARKLING MACHINERY’s Role: Parts, Service, and Sustainable Solutions

- How quality parts enable greener operations

- Technical support and customization

- Implementing a Practical Environmental Action Plan

- Step-by-step guide for fleet managers

- Measuring success

- Trade-offs and Practical Considerations

- Cost, performance, and compatibility

- Conclusion: Balance Performance with Responsibility

- Summary and call to action

- FAQ: Common Questions About Excavator Hydraulic Fluids and the Environment

- Q1: Are biodegradable hydraulic fluids always the best choice?

- Q2: How can I tell if a fluid is “readily biodegradable”?

- Q3: What immediate steps can operators take to reduce hydraulic fluid spills?

- Q4: Can used biodegradable hydraulic fluids be recycled?

- Q5: How do Excavator Hydraulic Parts from SPARKLING MACHINERY help reduce environmental risk?

Introduction: Why Excavator Hydraulic Fluids Matter for the Environment

Context and relevance to Excavator Hydraulic Parts

Hydraulic systems power excavators’ digging, slewing, and lifting. The fluids inside those systems—whether mineral oil, synthetic esters, or water-based fluids—directly affect operational performance and long-term environmental risk. Selecting robust Excavator Hydraulic Parts and proper fluids reduces leaks, contamination, and disposal issues while meeting growing regulatory and customer expectations for sustainability.

How Hydraulic Fluids Cause Environmental Harm

Pathways: leaks, spills, and routine disposal

Hydraulic fluid can reach the environment through small continuous leaks from hoses and seals, accidental spills during refilling or maintenance, and improper disposal of used oil and contaminated filters. Even small volumes can impact sensitive sites: a few liters pooled on soil can migrate to groundwater or surface waters, creating localized contamination.

Persistent pollution and toxicity

Traditional mineral oil-based hydraulic fluids can contain polycyclic aromatic hydrocarbons (PAHs) and other constituents that are persistent in soil and water and toxic to aquatic life. These compounds resist biodegradation and can accumulate in sediments, leading to long-term ecological effects.

Fire and air emissions

Certain hydraulic fluids (e.g., phosphate esters) are used for fire resistance but can form hazardous combustion byproducts when burned. Operations that vent or burn contaminated rags or fluids may release volatile organic compounds (VOCs) and other pollutants to air.

Types of Excavator Hydraulic Fluids and Their Environmental Profiles

Common fluid categories

Hydraulic fluids used in excavators typically fall into a few families: mineral oil-based fluids, synthetic esters (including biodegradable ester-based fluids), polyalkylene glycols (PAGs), and water-glycol or phosphate ester fire-resistant fluids. Each type has different biodegradability, toxicity, and performance trade-offs.

Biodegradability standards you should watch

When assessing environmental performance, look for fluids tested to internationally recognized methods. The OECD 301 series (for example, 301B) defines “ready biodegradability” as ≥60% biodegradation within 28 days. Fluids that meet this benchmark are less likely to persist if spilled. Also check aquatic toxicity tests (e.g., LC50 for fish or EC50 for Daphnia) and approvals/labels from recognized eco-certifications.

Practical Table: Comparing Hydraulic Fluid Types

Quick comparison to guide selection

Below is a concise comparison of common hydraulic fluid types and their typical environmental and operational traits.

| Fluid Type | Biodegradability | Fire Resistance | Typical Uses | Pros / Cons |

|---|---|---|---|---|

| Mineral oil | Low (not readily biodegradable) | Low | General construction equipment | Good performance/cost; persistent if spilled |

| Synthetic ester (biodegradable) | Often high (can meet OECD 301 ≥60%) | Varies (usually moderate) | Environmentally sensitive sites, forestry, marine | Lower persistence; may require compatibility checks with seals |

| Polyalkylene glycol (PAG) | Variable (some formulations are biodegradable) | Moderate | Specific OEM applications | Good lubricity; compatibility and biodegradability vary |

| Water-glycol / phosphate ester | Low to moderate (depends on formulation) | High (fire-resistant) | High fire-risk applications | Fire-safe; may have higher corrosion risk and disposal complexity |

Mitigation Strategies: Design, Parts, and Practices

Choose the right Excavator Hydraulic Parts to reduce leaks

High-quality components—hoses, fittings, seals, valves—are the first line of defense. Using precision-engineered Excavator Hydraulic Parts from trusted suppliers such as SPARKLING MACHINERY reduces failure rates. Upgrading to improved sealing technologies and corrosion-resistant fittings lowers leak frequency.

Specify environmentally preferable hydraulic fluids

For work near water or in protected areas, specify fluids that demonstrate ready biodegradability (OECD 301 series) and low aquatic toxicity. Confirm compatibility with OEM components and operating temperatures. Discuss trade-offs with your supplier: biodegradable esters often provide good lubricity but may need compatible seal materials and careful thermal management.

Preventive maintenance and fluid monitoring

Routine inspection and proactive replacement of hoses, couplers, and seals are critical. Implement scheduled fluid analysis (e.g., particle counts, viscosity, water content) to extend life while preventing gear wear that can lead to catastrophic leaks. A well-kept hydraulic system reduces the chance of sudden large spills.

Containment and spill response

On-site measures are essential: secondary containment for storage drums, drip trays around fill points, absorbent pads at likely leak points, and spill kits tailored for hydraulic fluids. Operators should be trained in quick containment and cleanup to prevent fluids reaching soil or drains. In the U.S., ensure compliance with EPA SPCC (Spill Prevention, Control, and Countermeasure) where applicable; in the EU follow local water protection directives.

Used Fluid Management and Recycling

Safe collection and segregation

Collect used hydraulic oil, filters, and contaminated rags in labeled, closed containers. Keep biodegradable and non-biodegradable fluids segregated to avoid contamination that could complicate recycling or re-refining.

Re-refining and proper disposal

Where possible, send used oils to certified re-refiners. Modern re-refining processes can recover base oil and remove contaminants, reducing lifecycle emissions compared with incineration or landfill. For contaminated solids (e.g., filters or sorbents), follow local hazardous waste rules—these items often require disposal through licensed waste handlers.

Operational Case: How Much Fluid Are We Talking About?

Typical hydraulic reservoir volumes and risk scale

Hydraulic reservoir sizes vary by machine size: mini excavators often hold ~30–50 liters, medium machines commonly 60–150 liters, and large excavators may hold 200–400 liters or more. Even a relatively small leak of 20 liters can create a substantial local contamination event if not contained, especially near waterways. This scale shows why both preventative parts quality and rapid response are important.

Regulatory and Stakeholder Considerations

Compliance with environmental regulations

Regulations differ by jurisdiction but commonly require measures to prevent stormwater contamination, proper storage of oils, and correct disposal of waste fluids. For example, in the U.S., the Clean Water Act and state-level spill rules apply to discharges to waters; operators should maintain records of disposal and spill response. In the EU, water protection directives and national regulations impose similar obligations.

Client expectations and procurement policies

Many clients and contractors now prefer or require biodegradable fluids and documented spill prevention strategies for projects in sensitive areas. Demonstrating responsible procurement of Excavator Hydraulic Parts and environmentally preferable fluids can be a differentiator in bids.

SPARKLING MACHINERY’s Role: Parts, Service, and Sustainable Solutions

How quality parts enable greener operations

SPARKLING MACHINERY, founded in 2013, supplies high-quality Excavator Hydraulic Parts—hydraulic components, undercarriage parts, and accessories—compatible with major brands such as Caterpillar, Komatsu, Hitachi, and Volvo. By offering precision-manufactured hoses, valves, and seals, SPARKLING helps reduce leak rates and extend component life, directly lowering environmental risk.

Technical support and customization

SPARKLING offers customized solutions and technical support to ensure fluid–component compatibility when customers switch to biodegradable or alternative hydraulic fluids. Proper selection of seals and hoses and tailored maintenance plans reduce unexpected failures and environmental incidents.

Implementing a Practical Environmental Action Plan

Step-by-step guide for fleet managers

1) Audit: Inventory hydraulic reservoir sizes and identify high-risk machines and sites (near water or in protected zones). 2) Parts upgrade: Replace worn hoses and seals with certified Excavator Hydraulic Parts. 3) Fluid choice: Pilot biodegradable fluids on a few machines, test for compatibility and performance. 4) Monitoring: Implement oil analysis and leak-inspection checklists. 5) Containment: Add bunds, drip trays, and spill kits at maintenance points. 6) Disposal contracts: Partner with licensed re-refiners and waste handlers. 7) Training: Train operators and maintenance teams on spill response and proper handling.

Measuring success

Track metrics such as the number of leaks per 1,000 operating hours, volumes of used oil sent for re-refining, and response times to spills. Reduced incident rates and documented recycling volumes both improve compliance and demonstrate performance to stakeholders.

Trade-offs and Practical Considerations

Cost, performance, and compatibility

Biodegradable fluids can cost more per liter than standard mineral oils and may require seal and hose compatibility checks. However, the total cost of ownership often improves when you factor in reduced environmental risk, lower cleanup costs, and fewer regulatory penalties. Run pilot tests and consult your Excavator Hydraulic Parts supplier to ensure safe upgrades.

Conclusion: Balance Performance with Responsibility

Summary and call to action

Mitigating the environmental impact of excavator hydraulic fluids is achievable by combining high-quality Excavator Hydraulic Parts, smart fluid selection, proactive maintenance, and proper waste management. SPARKLING MACHINERY can support equipment owners with reliable parts, technical advice, and customized solutions to help protect the environment while maintaining machine performance. Start with an audit and a pilot program—small steps can yield measurable reductions in environmental risk.

FAQ: Common Questions About Excavator Hydraulic Fluids and the Environment

Q1: Are biodegradable hydraulic fluids always the best choice?

A: Biodegradable fluids reduce persistence and often lower aquatic toxicity, making them preferable in sensitive locations. However, they must be compatible with seals and system materials and meet performance needs in your temperature range. Pilot testing is recommended.

Q2: How can I tell if a fluid is “readily biodegradable”?

A: Look for test data from recognized methods such as the OECD 301 series. “Ready biodegradability” is commonly defined as ≥60% degradation within 28 days under OECD 301 tests.

Q3: What immediate steps can operators take to reduce hydraulic fluid spills?

A: Inspect hoses and fittings regularly, use drip trays at fill points, store oil drums in secondary containment, keep spill kits on-site, and train operators in quick containment procedures.

Q4: Can used biodegradable hydraulic fluids be recycled?

A: It depends on contamination and the recycling facility. Some re-refiners accept certain biodegradable fluids, but segregation from mineral oil is important. Work with certified collectors to determine options.

Q5: How do Excavator Hydraulic Parts from SPARKLING MACHINERY help reduce environmental risk?

A: SPARKLING provides precision-manufactured hoses, seals, valves, and hydraulic components compatible with major brands. Higher-quality parts lower failure and leak rates, support compatibility with alternative fluids, and reduce maintenance frequency, all of which reduce environmental exposure.

Testing Protocols for SK460-8 SK480-8 Low Pressure Sensors

Best AC compressor for excavator manufacturers and supplier brands

Wholesale excavator control column manufacturer and supplier

Best professional excavator engine overhaul kit manufacturers and supplier brands

faq

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

31E3-3187 Accumulator for Hyundai excavators R140W-9 R170W-7 R180W-9 R210W-9 and Case E18C CX37C

The 31E3-3187 Hydraulic Accumulator is a premium diaphragm-type accumulator engineered for Hyundai wheeled excavators (R140W-9/R170W-7/R180W-9/R210W-9) and Case mini-excavators (E18C/CX37C). It stabilizes hydraulic system pressure, absorbs shock waves, and stores energy for peak-demand operations, preventing component fatigue and extending service life in high-vibration construction environments.

Key Features

· OEM-Matched Precision: 0.35L volume, 31.5MPa max working pressure, and diaphragm design for consistent pressure regulation and energy storage.

· High-Strength Construction: Carbon steel body with anti-corrosion coating and reinforced crimped end caps for 10,000+ hours service in harsh conditions.

· Leak-Proof & Shock-Absorbent: Nitrile rubber diaphragm and O-ring seals eliminate fluid leakage; absorbs pressure spikes up to 42MPa to protect valves/pumps.

· Plug-and-Play Fit: Direct bolt-on mounting with 3/4" NPT port; no modification needed for Hyundai/Case excavator installation.

Compatible Equipment

· Excavators: Hyundai R140W-9, R170W-7, R180W-9, R210W-9; Case E18C, CX37C; also fits Hyundai R200W-7, R170W-9.

· Interchangeable Part Numbers: 31E3-3187, 31MN-90680, 31E33187.

Construction Spare Parts VOE14577744 RELIEF VALVE for Volvo Excavators EC330B EC330C EC340D EC360

SPARKLING MACHINERY NEW EC330B EC330C EC340D EC360B EC380D VOE14577744 Relief Valve is a dedicated, high-precision hydraulic component exclusively engineered for VOLVO EC330B, EC330C, EC340D, EC360B, and EC380D crawler excavators—heavy-duty equipment critical for large-scale mining, construction, and infrastructure projects. As a core safety and pressure-regulating part of the excavator’s hydraulic system, it monitors hydraulic pressure in real time and automatically releases excess pressure to prevent overloading of key components like hydraulic pumps, cylinders, and valves. This function is vital for maintaining stable hydraulic operation during high-intensity tasks such as rock breaking, bulk ore loading, and deep excavation, avoiding pressure-surge damage and ensuring uninterrupted workflow.

Engineered to meet VOLVO’s original equipment (OEM) standards and marked with the genuine part number VOE14577744, the relief valve withstands harsh conditions: high hydraulic pressure (up to 42 MPa), extreme temperature fluctuations (-25°C to 105°C), and continuous heavy-duty vibration. It maintains precise pressure regulation accuracy and resists oil contamination, providing long-lasting reliability for the excavators’ hydraulic systems. Backed by strict performance verification, it guarantees seamless compatibility and operational safety for EC330B/EC330C/EC340D/EC360B/EC380D models.

Rexroth Relief Valve 04950403 R901102333 – 350 Bar Screw‑In Cartridge

The Rexroth Relief Valve 04950403 (part no. R901102333) is a precision-engineered screw-in cartridge valve designed for hydraulic systems in excavators and industrial machinery. This robust, direct-acting spool-type valve offers pressure reducing and relieving capabilities, withstanding up to 350 bar of maximum operating pressure and supporting flow rates around 30 L/min. Constructed with quality materials and standard CAAN cavity compatibility, it ensures responsive, leak-free hydraulic control under demanding conditions.

Premium XKCH-00022 solenoid valve fits Hyundai R125LCR-9A, R145CR9, R160LC9A, and R180LC9S excavators. Reliable hydraulic control part from SPARKLING

The XKCH-00022 Solenoid Valve is a precision-engineered hydraulic control component used in multiple Hyundai crawler excavators, including models R125LCR-9A, R145CR9, R160LC9A, and R180LC9S.

This solenoid valve plays a vital role in directing hydraulic fluid flow in key systems such as travel, swing, or attachment control. Engineered for responsive performance and long-lasting durability, this part ensures accurate actuation and helps maintain overall machine efficiency.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879