KHR50008 Control Unit

The KHR-series Electronic Control Units (ECUs) are advanced engine and hydraulic control modules specially designed for CASE CX-series crawler excavators, including CX130DLC, CX250DLC, CX300DLC, and CX490DLC.

These ECUs—part numbers KHR50000 to KHR50017—manage core operational functions such as engine response, fuel injection, hydraulic system regulation, and machine diagnostics, ensuring smooth operation, fuel efficiency, and maximum productivity on-site.

Engineered for OEM-level compatibility and reliability, each unit is:

-

Pre-programmed and ready for installation

Ideal for repair, replacement, or equipment upgrading, this electronic control system ensures optimal machine performance with minimal downtime.

SPARKLING KHR50008 Control Unit – Precision & Reliability for Your Excavator

SPARKLING MACHINERY, established in 2013, proudly presents the KHR50008 control unit—a pinnacle of stability, precision, and durability designed to optimize your excavator’s performance. Engineered with cutting-edge technology and subjected to rigorous quality control, the KHR50008 control unit seamlessly integrates with top-tier excavator brands such as Caterpillar, Komatsu, Hitachi, and Volvo, ensuring superior compatibility and enhanced functionality.

This control unit is crafted to withstand harsh operational environments, providing consistent and reliable control over hydraulic systems and electrical components. Its advanced design supports improved responsiveness and operational efficiency, minimizing downtime and maintenance costs. Whether you operate in construction, mining, or heavy-duty excavation, the KHR50008 control unit delivers unmatched precision that boosts productivity and prolongs equipment lifespan.

At SPARKLING MACHINERY, we combine technical expertise with a customer-first approach. We offer tailored solutions and comprehensive technical support, ensuring that every unit meets your specific requirements. Our commitment to altruism and innovation guarantees that you receive top-quality parts at competitive prices, helping you reduce operational costs without compromising performance.

With a global presence and an expansive product range—including hydraulic components, undercarriage systems, engine parts, cabs, mini excavators, and accessories—SPARKLING MACHINERY stands as your trusted partner in the excavator parts industry. Choose the KHR50008 control unit to experience reliable control, enhanced durability, and superior operational precision that empower your equipment for any challenge.

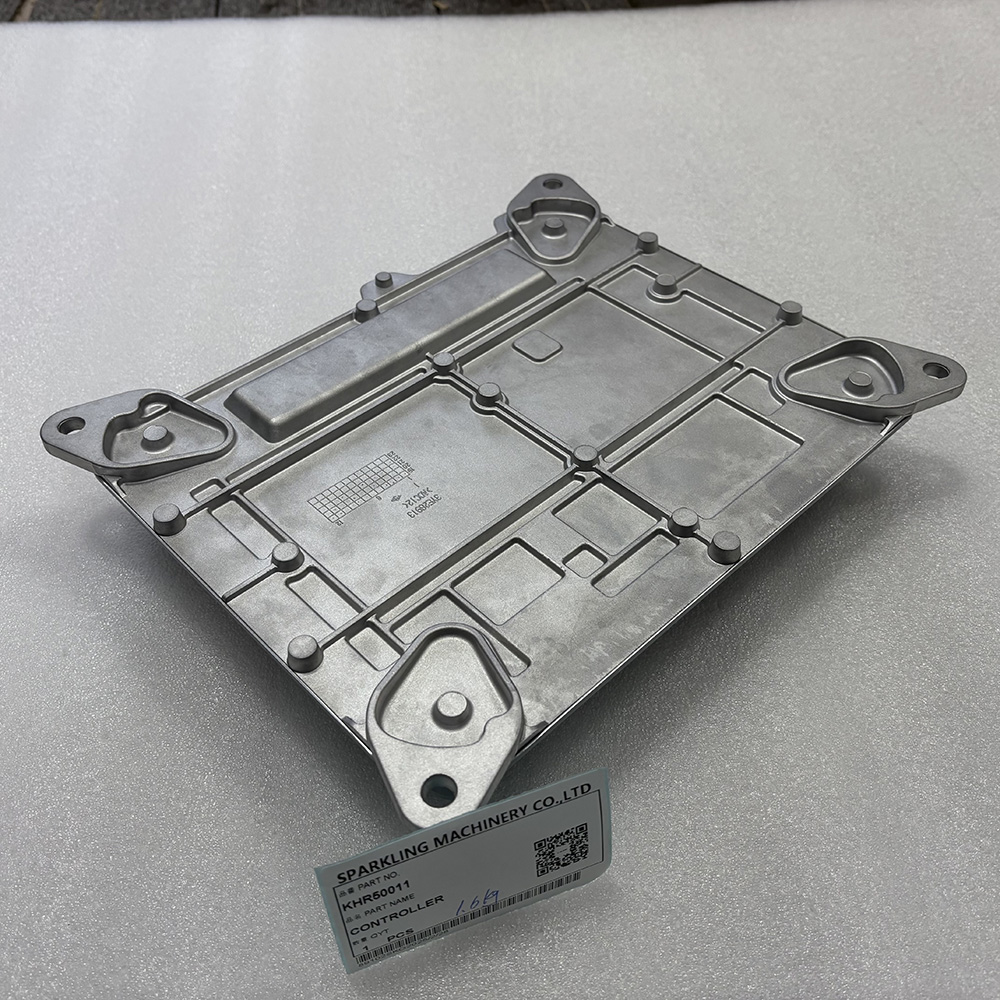

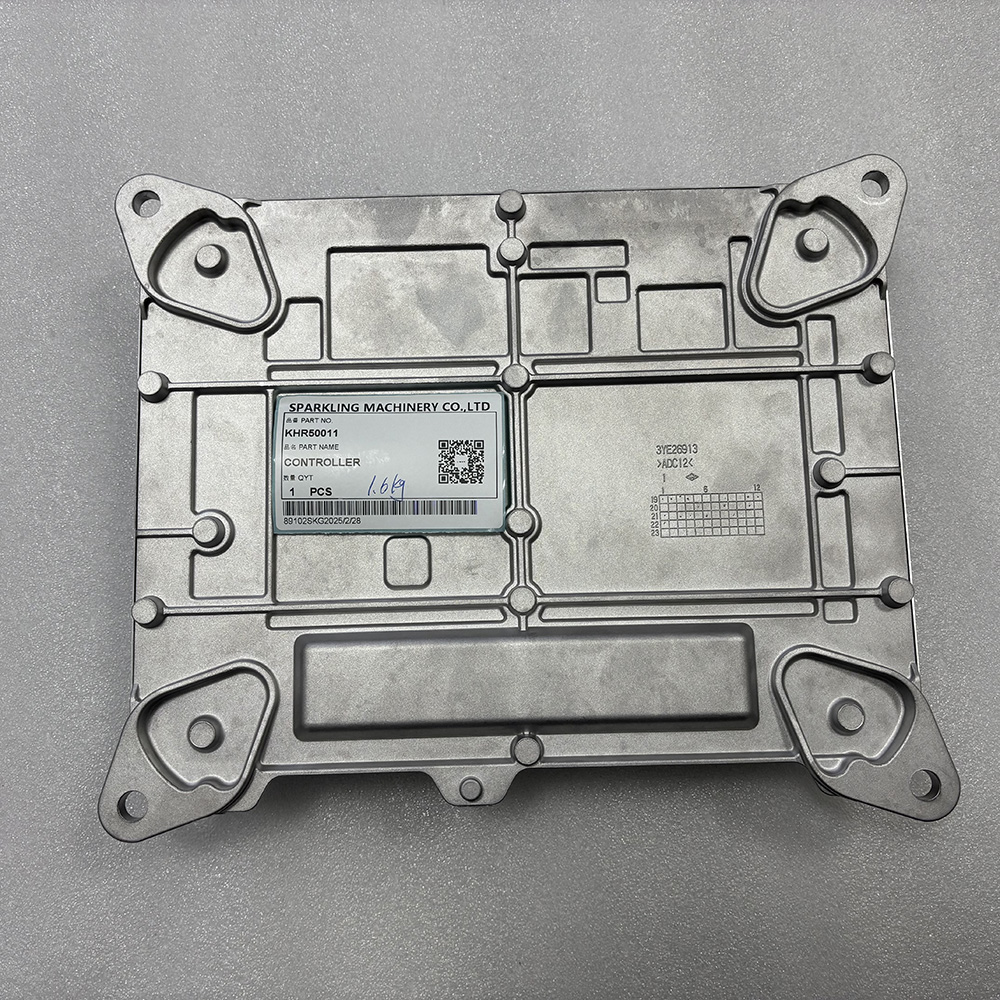

Product Images

Q&A

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

CX130DLC CX300DLC CX490DLC CX250DLC CRAWLER EXCAVATOR KHR50000 KHR50008 KHR50009 KHR50011 KHR50013 KHR50014 KHR50015 KHR50017 ELECTRONIC CONTROL UNIT

The KHR-series Electronic Control Units (ECUs) are advanced engine and hydraulic control modules specially designed for CASE CX-series crawler excavators, including CX130DLC, CX250DLC, CX300DLC, and CX490DLC. These ECUs—part numbers KHR50000 to KHR50017—manage core operational functions such as engine response, fuel injection, hydraulic system regulation, and machine diagnostics, ensuring smooth operation, fuel efficiency, and maximum productivity on-site. Engineered for OEM-level compatibility and reliability, each unit is: Pre-programmed and ready for installation

CATERPILLAR EXCAVATOR PARTS MADE IN CHINA NEW 301.5 302.5 303 303.5 156-8847 SOLENOID SPARKLING MACHINERY

SPARKLING MACHINERY NEW 301.5 302.5 303 303.5 156-8847 Solenoid is a dedicated electrical control component for CATERPILLAR 301.5, 302.5, 303, and 303.5 mini crawler excavators (versatile for landscaping, indoor demolition, and small-scale construction). As a key switch for the excavator’s hydraulic or fuel systems, it converts electrical signals into mechanical action to control valve opening/closing, ensuring precise operation of functions like bucket tilting and arm movement during delicate tasks.

Meeting CATERPILLAR OEM standards (part no. 156-8847), it endures -30°C to 85°C temperatures, resists vibration and electrical interference, and maintains stable switching performance. Strict testing guarantees seamless compatibility and long-term reliability for the four CATERPILLAR models.

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EC160B EC180B EC240B EC240C FC2924C SA7270-11040/11211419 VALVE SPARKLING MACHINERY

SPARKLING MACHINERY NEW EC160B EC180B EC240B EC240C FC2924C SA7270-11040/11211419 Valve is a dedicated hydraulic control component for Volvo EC160B, EC180B, EC240B, EC240C, and FC2924C crawler excavators (widely used in construction, mining, and infrastructure projects). As a core part of the excavator’s hydraulic system, it regulates oil flow, pressure, and direction to control key functions like boom lifting, bucket digging, and swing movements—ensuring smooth, precise operation during high-intensity tasks.

Meeting Volvo OEM standards (part nos. SA7270-11040/11211419), it endures 32 MPa working pressure, -30°C to 90°C temperatures, resists oil corrosion and vibration, and maintains leak-free performance. Strict testing guarantees seamless compatibility with the five Volvo models and long-term hydraulic system stability.

VOLVO HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW VOE21379931 INJECTOR SPARKLING MACHINERY

SPARKLING MACHINERY NEW VOE21379931 Injector is a core engine fuel supply component for Volvo excavators (heavy-duty construction/mining use). It precisely atomizes and injects fuel into cylinders to ensure efficient combustion and stable power output.

Meeting Volvo OEM standards (VOE21379931), it resists up to 280°C high temps and 180MPa pressure, guaranteeing seamless compatibility and long-term reliable fuel delivery performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879