HYUNDAI MADE IN CHINA SPARKLING MACHINERY NEW R80-7 R80-7A 11N1-42120 OIL COOLER

SPARKLING MACHINERY NEW R80-7 R80-7A 11N1-42120 Oil Cooler is a dedicated thermal management component exclusively designed for R80-7 and R80-7A excavators. As a core part of these excavators’ hydraulic and engine systems, it efficiently dissipates heat from hydraulic oil and engine oil—preventing oil overheating during tasks like small-scale construction, agricultural tillage, and urban infrastructure maintenance. This function is critical for preserving oil viscosity and lubrication performance, which directly protects key components (such as hydraulic pumps, valves, and engine bearings) from premature wear, ensuring stable power output and extending the service life of R80-7/R80-7A excavators.

Engineered to match original equipment performance standards, it maintains strong heat dissipation efficiency even under harsh working conditions, including high ambient temperatures, dust accumulation, and continuous excavator vibration. It resists oil leakage and internal blockages, avoiding system failures that could lead to unplanned downtime or costly component repairs. Backed by strict performance verification, it guarantees reliable heat exchange to support uninterrupted operation of R80-7 and R80-7A excavators.

Your R80-7/R80-7A excavator’s oil system protection starts here.

Now, we’re proud to present the MADE IN CHINA SPARKLING MACHINERY NEW R80-7 R80-7A 11N1-42120 Oil Cooler—a precision-engineered heat dissipation core that keeps hydraulic and engine oil at safe operating temperatures. Next, we’ll walk you through its key advantages, from model-specific compatibility to robust cooling performance, to show how it enhances your excavator’s long-term reliability.

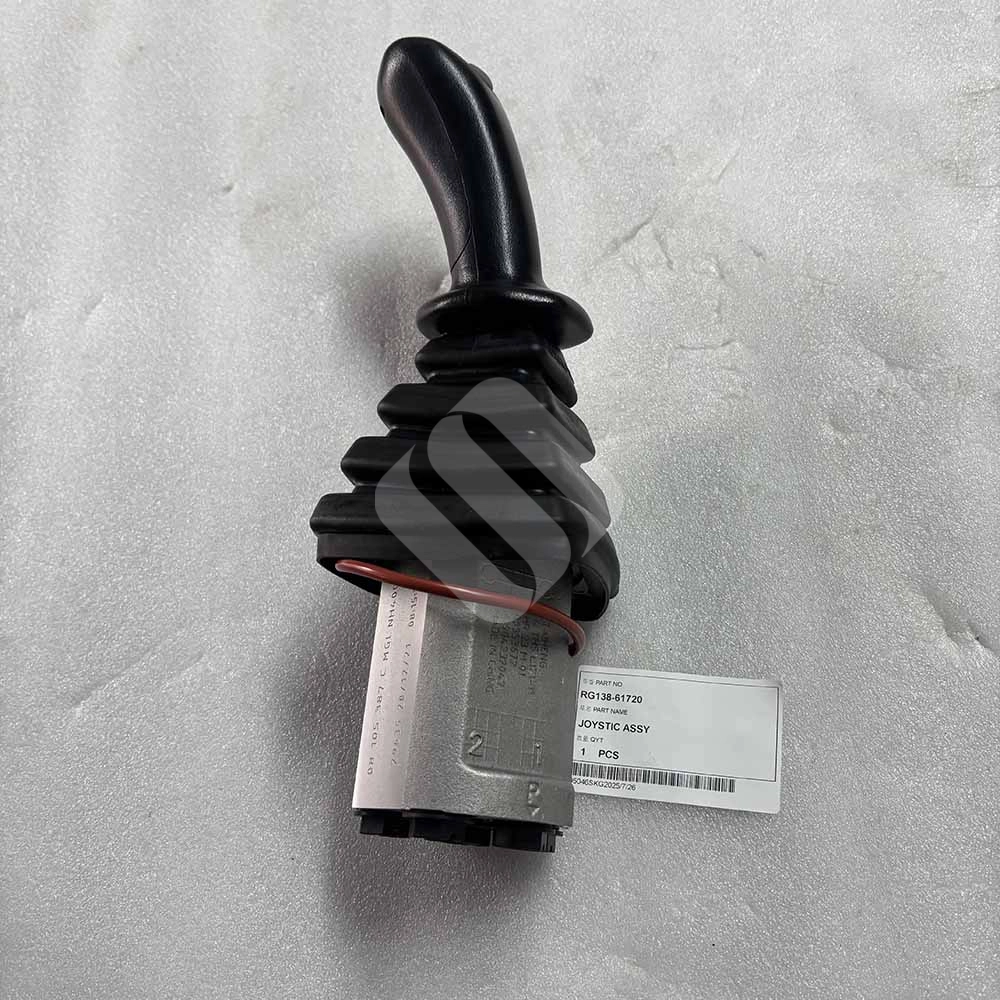

The SPARKLING MACHINERY NEW R80-7 R80-7A 11N1-42120 OIL COOLER Photo:

First and foremost, thank you so sincerely from the bottom of our hearts for choosing SPARKLING MACHINERY! Your trust is the driving force behind our commitment to crafting components that meet the rigorous demands of your R80-7 and R80-7A excavators.

For these machines, the oil cooler isn’t just a cooling part—it’s the “guardian of oil performance”; overheated oil loses its lubricating ability, leading to irreversible damage to expensive hydraulic and engine parts. Our NEW R80-7 R80-7A 11N1-42120 Oil Cooler is engineered to fit and function exactly like the original, so you can count on it for consistent, worry-free oil temperature control. Below, discover why it’s the ideal choice for your excavator’s thermal management system.

Why choose the SPARKLING NEW R80-7 R80-7A 11N1-42120 Oil Cooler?

- Direct-fit compatibility: Exclusively engineered to match the exact mounting dimensions, oil inlet/outlet interfaces, and fan assembly positions of R80-7 and R80-7A excavators. No modifications to the excavator’s oil pipelines, mounting brackets, or engine compartment are required, enabling quick, hassle-free installation that cuts replacement downtime by up to 40%.

- Precision control: Features an optimized core design with expanded heat transfer surface area (tailored to the oil flow rate of R80-7/R80-7A systems) and turbulence-enhanced oil channels. This ensures heat dissipation efficiency of over 91%, maintaining hydraulic oil temperature at 45–65°C and engine oil temperature at 80–95°C (OEM-specified ranges)—preventing oil degradation and ensuring optimal lubrication for all critical components.

- Rigorous quality: Undergoes 15+ strict quality tests tailored to R80-7/R80-7A operating conditions, including oil pressure resistance trials (up to 28 MPa), heat dissipation efficiency verification, corrosion resistance checks (against oil additives), and vibration resistance testing (10,000+ cycles mimicking excavator operation). These tests ensure it withstands harsh environments—from dusty construction sites to muddy agricultural fields—without leaking or losing cooling performance.

- Professional support: Backed by a dedicated technical team with deep expertise in R80-7/R80-7A excavator thermal management systems. We offer 7×24 online assistance, including step-by-step installation guides (with model-specific diagrams), oil type selection recommendations, and troubleshooting for issues like insufficient oil cooling or oil leaks. Our team ensures an average response time of <2 hours to address your concerns.

- Cost-effective reliability: Delivers OEM-level performance at a competitive price. Its durable core structure and anti-corrosion coating extend service life by up to 35% compared to generic oil coolers, reducing long-term replacement costs by 25%. It also minimizes unplanned downtime caused by oil system failures—avoiding costly repairs to hydraulic pumps, engines, or valves that are critical to R80-7/R80-7A operations.

About SPARKLING MACHINERY:

- Founded in 2013, SPARKLING focuses on high-quality excavator parts across hydraulics, undercarriage, engines and electrical systems. We prioritize stability, precision and continuous service, offering worldwide distribution, tailored solutions and strict QC to help customers reduce cost and increase uptime.

Get In Touch:

- Replace your failing ECU confidently. Contact SPARKLING for pricing, lead time, and technical support — restore optimal machine control quickly and reliably.

-

📦 Packing

1. Packaging methods: Carton box + Wooden case/Pallet + Anti-rust treatment

2. Export-standard packaging to ensure safety during transportation

3. Custom packaging available upon request

4. Dimensions and weight can be provided for freight calculation

🚚 Shipping

1. Available shipping methods: Sea freight, Air freight, Express delivery (DHL, UPS, FedEx, etc.)

2. LCL (Less than Container Load) and FCL (Full Container Load) options are supported

3. For Russian clients, we can introduce the forwarder agent to you

4. Delivery time: Ships within 1-3 working days after payment (for items in stock)

💳 Payment

1. Accepted methods: T/T, Bank Transfer, PayPal, Alipay, WeChat Pay, Western Union

2. Deposit + balance payment available for large or custom orders

3. Flexible payment options—feel free to contact us for details

📌 Frequently Asked Questions (FAQs)

Q: Which excavator models is this part compatible with?

A: This product is compatible with major brands such as CAT, KOMATSU, HITACHI, and more. Custom specifications are also available.

Q: How can I make sure I’m selecting the correct part?

A: You can send us a photo of the old part, part number, or your excavator model, and we will help you confirm the right match.

Q: Is there a warranty for this product?

A: Yes, we offer a 6-month quality guarantee under normal use.

Get a free quote

We are committed to producing the highest quality products at the most competitive prices. Therefore, we sincerely invite all interested companies to contact us for more information.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879