E235BSRLC Control Valve - Precision Hydraulic Solutions

E235BSRLC Control Valve: Reliable Hydraulic Performance

Engineered for High Precision and Stability

The E235BSRLC control valve from SPARKLING is designed to deliver exceptional hydraulic control, ensuring smooth and precise operation of your excavator. Manufactured with High Quality materials and advanced technology, this control valve supports stability and reduces downtime, making it ideal for heavy-duty applications.

Wide Compatibility with Leading Excavator Brands

Our E235BSRLC control valve is fully compatible with top excavator brands such as Caterpillar, Komatsu, Hitachi, and Volvo. Whether you need a replacement or an upgrade, SPARKLING ensures seamless integration with your existing hydraulic system, enhancing performance without compromise.

Durability Backed by Strict Quality Control

At SPARKLING MACHINERY, quality is paramount. Each E235BSRLC control valve undergoes rigorous testing and quality assurance processes to guarantee reliability under diverse working conditions. This commitment ensures long-lasting operation and reduced maintenance costs for your machinery.

Customized Solutions and Expert Technical Support

Beyond supplying quality parts, SPARKLING offers tailored solutions and expert consultation to meet your unique project needs. Our global service network provides continuous assistance, helping you optimize hydraulic performance while controlling costs effectively.

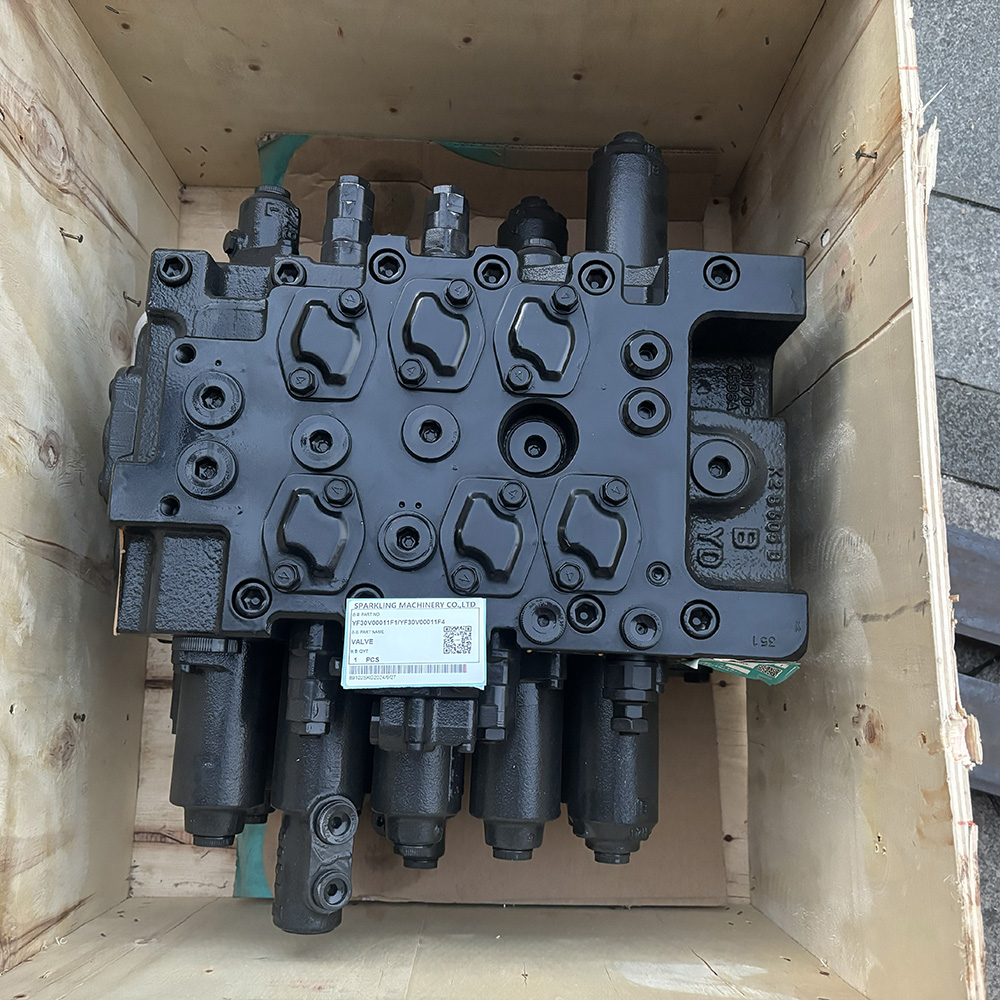

E235BSRLC control valve Display

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

XKAQ-00760 Shaft Compatible with Hyundai Crawler Excavators R290LC-7, R290LC-9, R300LC-9A & R290LC-9MH

XKAQ-00760 Shaft Compatible with Hyundai Crawler Excavators R290LC-7, R290LC-9, R300LC-9A & R290LC-9MH

VOE14531222 Radiator Compatible with Volvo EC210B & EC210BLC Excavators

VOE14531222 Radiator Compatible with Volvo EC210B & EC210BLC Excavators

Denso ND029600-0580 Sensor Compatible with Komatsu PC450-7 Excavator | SA6D140E & SAA6D140E Engines

Denso ND029600-0580 Sensor Compatible with Komatsu PC450-7 Excavator | SA6D140E & SAA6D140E Engines

LJ014700 Relief Valve Compatible with Case CX210B & CX220C LC Excavators

LJ014700 Relief Valve Compatible with Case CX210B & CX220C LC Excavators

KHR44570 KHR24470 Converter Compatible with Case CX130C CX160C CX210D Excavators & Sumitomo SH120 A2 730

KHR44570 KHR24470 Converter Compatible with Case CX130C CX160C CX210D Excavators & Sumitomo SH120 A2 730

250V 13A DRC16-24SA Connector - Construction Machinery Spare Parts

250V 13A DRC16-24SA Connector - Construction Machinery Spare Parts

XKAQ-00760 Shaft Compatible with Hyundai Crawler Excavators R290LC-7, R290LC-9, R300LC-9A & R290LC-9MH

XKAQ-00760 Shaft Compatible with Hyundai Crawler Excavators R290LC-7, R290LC-9, R300LC-9A & R290LC-9MH

VOE14531222 Radiator Compatible with Volvo EC210B & EC210BLC Excavators

VOE14531222 Radiator Compatible with Volvo EC210B & EC210BLC Excavators

Denso ND029600-0580 Sensor Compatible with Komatsu PC450-7 Excavator | SA6D140E & SAA6D140E Engines

Denso ND029600-0580 Sensor Compatible with Komatsu PC450-7 Excavator | SA6D140E & SAA6D140E Engines

LJ014700 Relief Valve Compatible with Case CX210B & CX220C LC Excavators

LJ014700 Relief Valve Compatible with Case CX210B & CX220C LC Excavators

KHR44570 KHR24470 Converter Compatible with Case CX130C CX160C CX210D Excavators & Sumitomo SH120 A2 730

KHR44570 KHR24470 Converter Compatible with Case CX130C CX160C CX210D Excavators & Sumitomo SH120 A2 730

250V 13A DRC16-24SA Connector - Construction Machinery Spare Parts

250V 13A DRC16-24SA Connector - Construction Machinery Spare Parts

3Kg Gear Pump 9218005 4276918 for Hitachi EX120-5, EX200-5, EX220-5 Excavators & John Deere 110, 120, 200LC

3Kg Gear Pump 9218005 4276918 for Hitachi EX120-5, EX200-5, EX220-5 Excavators & John Deere 110, 120, 200LC

3Kg Gear Pump 9217993 4181700 for Hitachi EX200-1, EX220-1, EX270-1 Excavators & John Deere 120C, 120D – High-Performance Replacement Pump

3Kg Gear Pump 9217993 4181700 for Hitachi EX200-1, EX220-1, EX270-1 Excavators & John Deere 120C, 120D – High-Performance Replacement Pump

8097954 Gasket Kit for FPT NEF 4.5L mechanical engines – Complete Replacement for Efficient Engine Repair

8097954 Gasket Kit for FPT NEF 4.5L mechanical engines – Complete Replacement for Efficient Engine Repair

12V DC Coil 6193716M1 for Terex TX760B, TLB815, TLB820 Machines | Solenoid Replacement Part

12V DC Coil 6193716M1 for Terex TX760B, TLB815, TLB820 Machines | Solenoid Replacement Part

High-Quality Bomag 05225332 Cylinder Roller Bearing – Durable Replacement Part for Bomag Equipment

High-Quality Bomag 05225332 Cylinder Roller Bearing – Durable Replacement Part for Bomag Equipment

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879