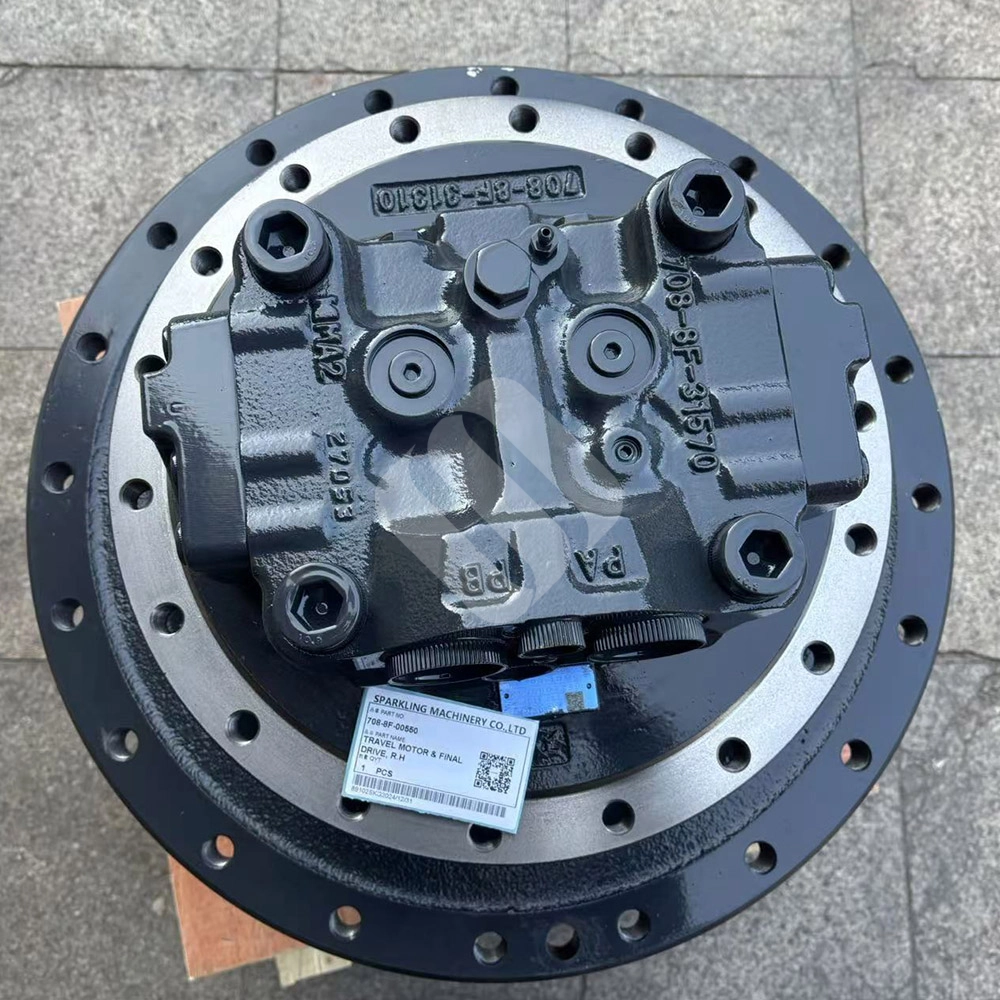

RH LH Final Drive by SPARKLING

SPARKLING MACHINERY offers reliable final drive assemblies (708-8F-00550 RH & 708-8F-00560 LH) for Komatsu PC210-10MO and PC215-10MO excavators. These durable, precision-fit travel motors ensure smooth power transmission and easy installation and come with fast delivery and competitive pricing.

RH LH Final Drive from SPARKLING MACHINERY

Discover reliable performance and advanced engineering with the RH LH final drive by SPARKLING, your trusted source for High Quality excavator parts. As part of the SPARKLING MACHINERY brand, founded in 2013, we are committed to the principles of stability, precision, and perseverance in every product we deliver.

Our RH LH final drive units are expertly crafted to ensure seamless compatibility with leading excavator brands such as Caterpillar, Komatsu, Hitachi, Volvo, and more. Each unit is engineered using high-quality materials and subjected to rigorous quality control, guaranteeing optimal performance and durability in the most demanding conditions.

SPARKLING MACHINERY offers not just components, but complete solutions—including technical support, meticulous consultation, and ongoing service. We provide customized products tailored to your excavation needs and maintain a competitive edge by balancing affordability with uncompromising quality.

Our commitment extends to a comprehensive range of excavator parts, including hydraulic components, undercarriage systems, engine and electrical components, cabs, mini excavators, and accessories. With a global sales network, responsive customer service, and a reputation for reliability, SPARKLING is the excavator partner you can trust.

Choose SPARKLING MACHINERY’s RH LH final drive for peace of mind, reduced downtime, and lasting value. Let our innovation and dedication drive your success in every project.

Detailed display

Question you may concern

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

About other questions pls contact me directily.

COUPLING FOR CATERPILLAR 236D 242D 246D 257D 259D CA3453548 345-3548 3453548

The Coupling (CA3453548 / 345-3548 / 3453548) is a high-quality replacement component designed for Caterpillar skid steer loaders and compact equipment, including models 236D, 242D, 246D, 257D, and 259D. This coupling ensures secure and reliable connection between shafts in hydraulic or drive systems, enabling efficient power transmission while reducing vibration and wear. Manufactured to meet or exceed OEM specifications, it delivers durable performance and long service life in heavy-duty construction and industrial applications.

Key Features

OEM-Compatible Fit: Direct replacement for Caterpillar part numbers CA3453548 / 345-3548 / 3453548 for accurate fit and performance

Durable Construction: Made from high-strength steel or alloy for superior wear resistance and long-term reliability

Efficient Power Transmission: Ensures smooth torque transfer and reduces vibration in drive or hydraulic systems

Benefits

Restores reliable power transmission and machine performance

Reduces wear and vibration in connected systems

Extends service life of hydraulic or drive components

Simplifies maintenance with direct OEM-fit replacement

Isuzu MADE IN CHINA SPARKLING MACHINERY NEW 8-98238255-2 EGR VALVE

SPARKLING MACHINERY NEW 8-98238255-2 EGR Valve is a premium China-made emissions control component designed for compatible diesel-powered construction machinery (such as excavators, loaders) and industrial engines. As a core part of the Exhaust Gas Recirculation (EGR) system, it precisely regulates the flow of exhaust gas back into the engine’s intake manifold—reducing the combustion temperature to minimize the formation of nitrogen oxides (NOx), a major harmful emission. This ensures compliance with global emission standards (e.g., Tier 4 Final, Euro V) while maintaining engine power output for heavy-duty tasks like digging, lifting, and material handling in construction, mining, and urban infrastructure projects.

Engineered to original equipment standards, it maintains reliable performance even under harsh working conditions, including high exhaust temperatures (up to 650°C), vibration, and exposure to soot or exhaust contaminants. With a precision-machined valve stem and adaptive sealing design, it minimizes gas leakage and ensures smooth, responsive flow control. Backed by strict quality verification, it guarantees consistent emissions reduction and prevents EGR system-related engine issues, supporting uninterrupted machinery operation.

SHANTUI EXCAVATOR PARTS MADE IN CHINA NEW SD16 SD22 SD32 23Y-58D-15000 THERMOSTAT CONTROL PANEL SPARKLING MACHINERY

SPARKLING MACHINERY NEW SD16 SD22 SD32 23Y-58D-15000 Thermostat Control Panel is a dedicated temperature management component for Shantui SD16, SD22, and SD32 crawler dozers/excavators (widely used in construction, mining, and land reclamation). As the core of the equipment’s cooling system control, it monitors engine and hydraulic oil temperatures in real time, automatically adjusting fan speed or coolant flow to maintain optimal operating temperatures—preventing overheating during high-intensity tasks like heavy pushing, grading, or earthmoving.

Meeting Shantui OEM standards (part no. 23Y-58D-15000), it endures -30°C to 85°C temperatures, resists dust and vibration, and maintains stable data monitoring. Strict testing guarantees seamless compatibility with the three Shantui models and long-term reliable temperature control.

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW L90E L70E L60E A30D L150E 22996281 PRESSURE SWITCH SPARKLING MACHINERY

SPARKLING MACHINERY NEW L90E L70E L60E A30D L150E 22996281 Pressure Switch is a critical hydraulic safety monitoring component for Volvo L90E, L70E, L60E, A30D, and L150E excavators (widely used in construction, mining, and material handling projects). As the "hydraulic pressure alert trigger", it real-time monitors pressure fluctuations in hydraulic circuits—automatically sending signals to the excavator’s control unit when pressure exceeds or drops below safe thresholds. This ensures timely protection during tasks like lifting heavy loads or digging, preventing overpressure damage to pumps/valves and underpressure-related operational failures.

Meeting Volvo OEM standards (part no. 22996281), it endures -30°C to 95°C temperatures, resists hydraulic oil corrosion and vibration, and guarantees reliable pressure sensing. Strict testing ensures seamless compatibility with the five Volvo models and long-term hydraulic system safety.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879