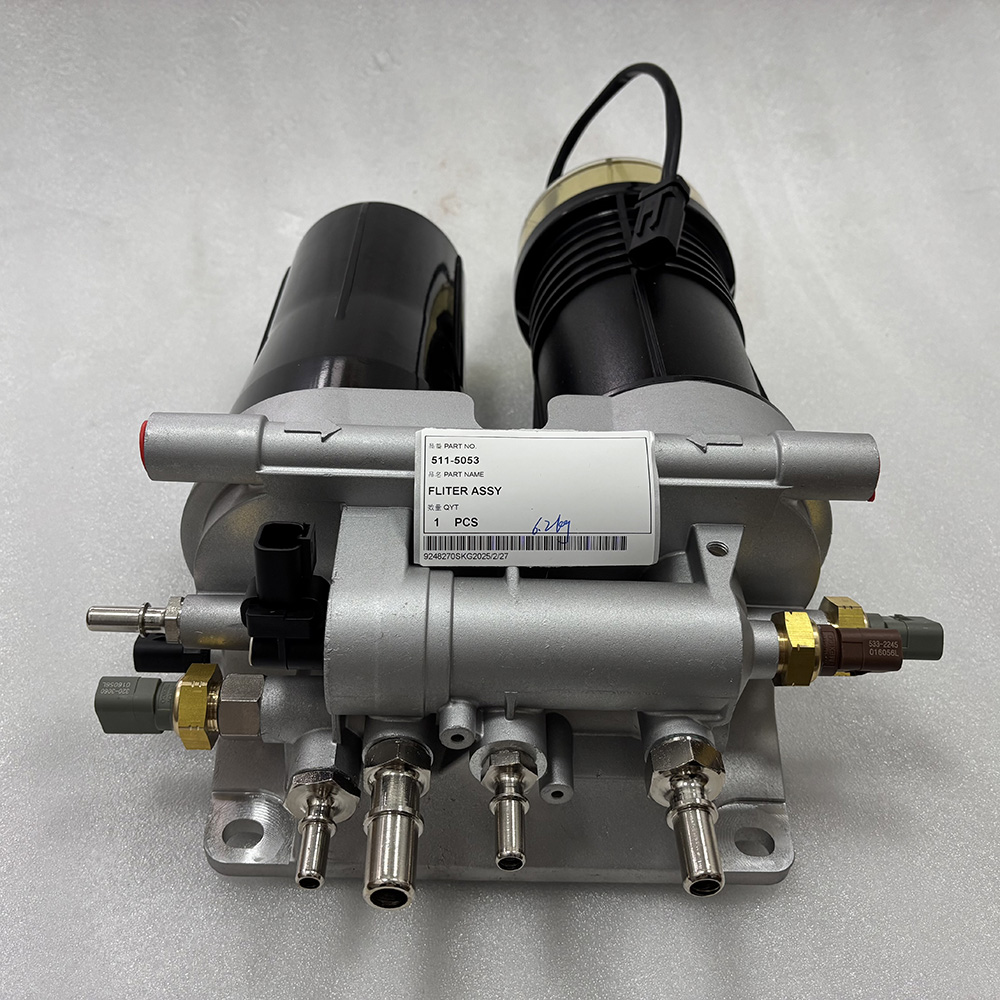

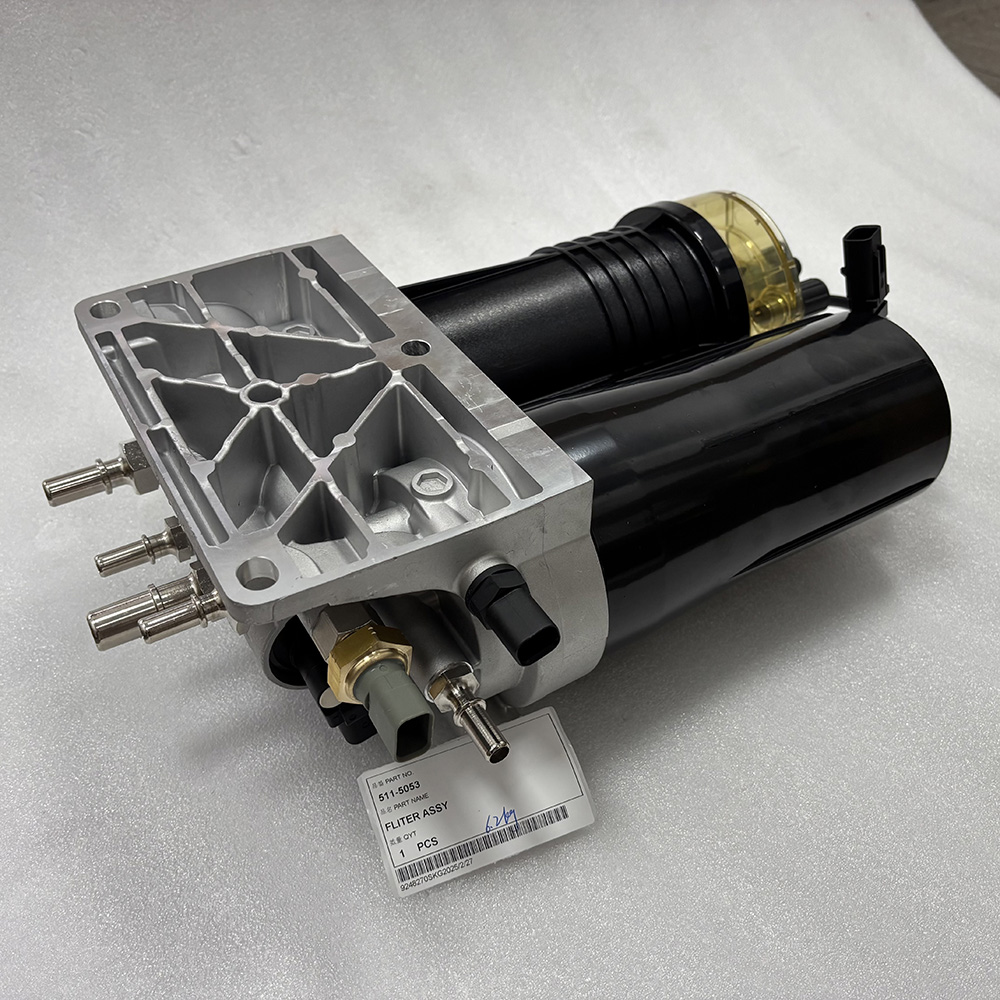

SPARKLING CAT 320 Fuel Water Separator – Reliable Excavator Parts

The 511-5053 Fuel Water Separator Filter is designed to protect your CAT 320, 330, 320GC, and 323 series excavators from fuel contamination and moisture damage. Engineered to meet or exceed Caterpillar OEM standards, this 6.2kg high-efficiency fuel filter ensures cleaner combustion, extended engine life, and optimal fuel system performance.

With advanced multi-layer filtration media, this filter effectively separates water from diesel fuel, preventing injector wear, corrosion, and cold-start issues. Ideal for harsh job sites, this unit supports long service intervals and stable engine operation.

Manufactured and quality-checked by SPARKLING MACHINERY, this unit offers genuine-level performance at a competitive price—your smart choice for reliable excavator maintenance.

SPARKLING CAT 320 Fuel Water Separator – Reliable Performance for Your Excavator

SPARKLING MACHINERY, established in 2013, specializes in High Quality excavator parts designed for durability and precision. Our CAT 320 fuel water separator is engineered to enhance fuel system efficiency by reliably removing water and contaminants from diesel fuel. This critical component protects your excavator’s engine from corrosion, reduces wear, and ensures smooth, uninterrupted operation even in the most demanding environments.

Manufactured under strict quality control protocols, the SPARKLING CAT 320 fuel water separator delivers exceptional stability and performance. Fully compatible with Caterpillar machinery, it undergoes rigorous testing to meet OEM standards, providing you with peace of mind and dependable reliability. Whether you operate in construction, mining, or any heavy-duty application, our fuel water separator helps lower maintenance costs and extend engine life.

Backed by SPARKLING’s commitment to innovation and customer service, each product comes with expert technical support and tailored consultation for your specific needs. Our global sales network ensures prompt availability, enabling seamless supply and continued productivity. Choose SPARKLING for fuel water separators that combine advanced engineering with competitive pricing – your trusted partner in excavator maintenance and part replacement.

Product Images

Question you may concern

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

If you have any other questions, please write email to us or call us , we will reply you as soon as possible.

EXCAVATOR 320 330 320 GC 323 511-5053 5115053 FILTER GP-WATER SEPARATION 6.2KG

The 511-5053 Fuel Water Separator Filter is designed to protect your CAT 320, 330, 320GC, and 323 series excavators from fuel contamination and moisture damage. Engineered to meet or exceed Caterpillar OEM standards, this 6.2kg high-efficiency fuel filter ensures cleaner combustion, extended engine life, and optimal fuel system performance.

With advanced multi-layer filtration media, this filter effectively separates water from diesel fuel, preventing injector wear, corrosion, and cold-start issues. Ideal for harsh job sites, this unit supports long service intervals and stable engine operation.

Manufactured and quality-checked by SPARKLING MACHINERY, this unit offers genuine-level performance at a competitive price—your smart choice for reliable excavator maintenance.

Excavator Spare Parts 4063844 FUEL INJECTION PUMP for Cummins Engine 6B5.9 6BT 5.9L 6BTAA 5.9L QSB5.9 Komatsu Excavator PC200-7 PC220-7

The Excavator Spare Parts 4063844 FUEL INJECTION PUMP is a premium engine fuel system core component meticulously engineered for Cummins Engines (6B5.9, 6BT 5.9L, 6BTAA 5.9L, QSB5.9) and specifically tailored to meet the high-precision fuel delivery demands of Komatsu PC200-7 and PC220-7 excavators. As a critical part of the engine’s fuel supply system, this fuel injection pump precisely controls fuel pressure, atomization, and injection timing, ensuring optimal combustion efficiency, consistent power output, and smooth engine operation. It delivers reliable performance even during prolonged heavy-duty construction tasks such as digging, lifting, and earthmoving, directly impacting fuel economy, engine responsiveness, and overall equipment productivity.

Designed to seamlessly integrate with Cummins engine architecture and Komatsu excavator systems, it enhances fuel system reliability, reduces emissions, and extends the service life of the machinery in harsh working environments.

Key Features

· Custom-engineered for perfect compatibility with Cummins 6B5.9, 6BT 5.9L, 6BTAA 5.9L, QSB5.9 engines and Komatsu PC200-7, PC220-7 excavators

· Precision fuel metering and timing control for optimized combustion and power delivery

· High-pressure resistance to withstand extreme fuel system demands

· Stable performance under varying operating conditions (load, temperature, altitude)

· Strict adherence to Cummins and Komatsu OEM specifications for seamless integration and consistent functionality

Compatible Models

· Cummins Engines: 6B5.9, 6BT 5.9L, 6BTAA 5.9L, QSB5.9

Komatsu Excavators (Equipped with above Cummins Engines): PC200-7, PC220-7

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EW160C EW160D EW160E EW180C VOE14558958 DISC BRAKE SPARKLING MACHINERY

SPARKLING MACHINERY NEW EW160C EW160D EW160E EW180C VOE14558958 Disc Brake is a dedicated safety component for VOLVO EW160C/EW160D/EW160E/EW180C wheeled excavators (versatile for road construction, municipal engineering). As the core of the excavator’s braking system, it delivers stable stopping force to ensure safe on-road travel (between job sites) and off-road operation (uneven terrain), preventing accidents during loading or navigation.

Meeting VOLVO OEM standards (part no. VOE14558958), it endures high friction, -30°C to 90°C temps, and vibration. It resists wear and corrosion, ensuring long-term braking reliability for the four VOLVO models, with strict testing guaranteeing compatibility and safe performance.

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EC350E EC380E EC380EHR EC460C EC460CHR 14622933 RELIEF VALVE SPARKLING MACHINERY

SPARKLING MACHINERY NEW EC350E EC380E EC380EHR EC460C EC460CHR 14622933 Relief Valve is a core hydraulic safety component for Volvo EC350E, EC380E, EC380EHR, EC460C, and EC460CHR excavators (widely used in heavy mining, large-scale construction, and infrastructure projects). As the "hydraulic pressure safety barrier", it automatically discharges excess pressure from hydraulic circuits during high-load tasks like rock breaking, deep digging, and heavy lifting—preventing overpressure damage to pumps, cylinders, and valves, while maintaining stable pressure for consistent equipment operation.

Meeting Volvo OEM standards (part no. 14622933), it endures -30°C to 95°C temperatures, resists hydraulic oil corrosion and vibration, and guarantees precise pressure relief triggering. Strict testing ensures seamless compatibility with the five Volvo models and long-term hydraulic system safety.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879