SPARKLING Excavator Cylinder Seals – Durable & Precise

The VOE14673442 Cylinder Seal Kit is designed to ensure optimal sealing performance for Volvo EW210C and EW210D wheeled excavators. Whether you're repairing a boom, arm, or bucket cylinder, this all-in-one hydraulic seal kit offers outstanding protection against fluid leakage, pressure loss, and external contamination.

Manufactured with high-quality materials like NBR, PU, and PTFE, this kit guarantees durability and resistance in the toughest job site conditions. It helps reduce downtime, extend cylinder lifespan, and maintain smooth hydraulic operations.

SPARKLING Excavator Cylinder Seals – Superior Durability and Precision

SPARKLING MACHINERY, established in 2013, is dedicated to delivering High Quality excavator cylinder seals designed for maximum efficiency and durability. Our excavator cylinder seals are engineered with precision to ensure optimal hydraulic performance, minimizing leakages and maintaining pressure under demanding conditions. Compatible with leading brands like Caterpillar, Komatsu, Hitachi, and Volvo, these seals meet the highest industry standards to enhance excavator reliability and lifespan.

Crafted using advanced materials and stringent quality control processes, SPARKLING’s cylinder seals offer outstanding resistance to wear, heat, and pressure. This robustness guarantees stable operation, reducing downtime and maintenance costs for heavy machinery operators. Our seals are customized to fit specific hydraulic systems, supporting smooth piston movement and extending part service life.

SPARKLING MACHINERY integrates innovation with perseverance, providing detailed technical support and personalized consultation throughout your purchase journey. We combine competitive pricing with unwavering quality to help customers optimize operational costs without compromising performance. Our global sales network ensures timely delivery and continuous service, making SPARKLING a trusted partner in the excavator industry.

Choose SPARKLING excavator cylinder seals for unparalleled quality, durability, and precision. Experience the difference that stability and innovation bring to your hydraulic systems and elevate your equipment’s productivity and reliability.

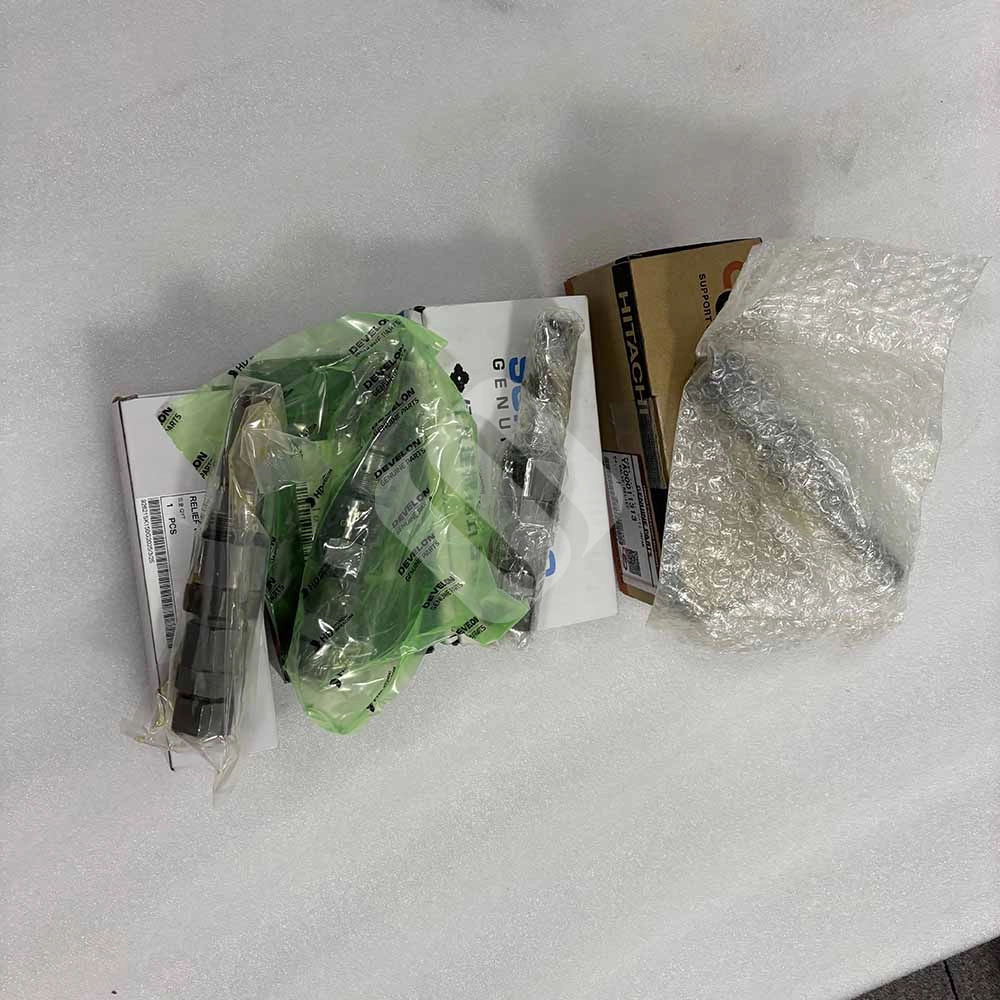

Product Image

FAQ

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

If you have any other questions, please write email to us or call us , we will reply you as soon as possible.

EW210C EW210D VOE 14673442 VOE14673442 STABILISER CYLINDER SEAL KIT

The VOE14673442 Cylinder Seal Kit is designed to ensure optimal sealing performance for Volvo EW210C and EW210D wheeled excavators. Whether you're repairing a boom, arm, or bucket cylinder, this all-in-one hydraulic seal kit offers outstanding protection against fluid leakage, pressure loss, and external contamination.

Manufactured with high-quality materials like NBR, PU, and PTFE, this kit guarantees durability and resistance in the toughest job site conditions. It helps reduce downtime, extend cylinder lifespan, and maintain smooth hydraulic operations.

Kobelco HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW ED150 140SR SK135SRLC-2 VA32G8701020 ECU SPARKLING MACHINERY

SPARKLING MACHINERY NEW ED150 140SR SK135SRLC-2 VA32G8701020 ECU is a core electronic control component for 3 Kobelco excavator models (construction/municipal use). It regulates engine, hydraulic, and operational systems to ensure precise, efficient performance.

Meeting Kobelco OEM standards (VA32G8701020), it resists -20°C to 85°C temps, voltage fluctuations, and electromagnetic interference, guaranteeing seamless compatibility and long-term reliable control.

Komatsu HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 14X-12-11103 DAMPER SPARKLING MACHINERY

SPARKLING MACHINERY NEW 14X-12-11103 Damper is a core vibration-damping component for Komatsu excavators (heavy-duty construction/mining use). It absorbs engine and transmission vibrations to reduce equipment noise, protect components, and ensure stable operation.

Meeting Komatsu OEM standards (14X-12-11103), it resists -30°C to 100°C temps, aging, and mechanical stress, ensuring seamless compatibility and long-term reliable vibration control performance.

Case EXCAVATOR PARTS MADE IN CHINA NEW CX350B CX290B LJ015170 RELIEF VALVE SPARKLING MACHINERY

SPARKLING MACHINERY NEW CX350B CX290B LJ015170 Relief Valve is a dedicated hydraulic safety component for Case CX350B and CX290B crawler excavators (widely used in construction, mining, and large-scale earthmoving). As a core part of the excavator’s hydraulic system, it monitors and limits maximum hydraulic pressure—preventing overpressure damage to pumps, cylinders, and valves during high-intensity tasks like heavy digging, rock breaking, and bulk material loading.

Meeting Case OEM standards (part no. LJ015170), it endures 32 MPa maximum pressure, -30°C to 95°C temperatures, resists oil corrosion and vibration, and maintains instant pressure relief response. Strict testing guarantees seamless compatibility with the two Case models and long-term hydraulic system protection.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879