SPARKLING HD512-III Travel Motor – Reliable Excavator Part

SPARKLING MACHINERY offers a premium Final Drive Assembly (619-62500001) paired with a high-strength Sprocket (317-50201000) for the Kato HD512-III excavator. This drive system is engineered for maximum torque, reliable track propulsion, and exceptional durability under rugged working conditions.

The Final Drive Assy transmits hydraulic power to the tracks with precision and is built using high-grade gears, seals, and housings. The Sprocket, heat-treated for wear resistance, guarantees smooth engagement with the track links and long service life even in abrasive environments.

SPARKLING HD512-III Travel Motor: Precision and Reliability for Your Excavator

Introducing the SPARKLING HD512-III travel motor, a high-performance solution designed to enhance the mobility and efficiency of your excavator. As part of SPARKLING MACHINERY’s extensive product lineup, the HD512-III travel motor embodies our commitment to stability, precision, and perseverance since 2013.

Crafted through rigorous manufacturing processes and stringent quality control, the HD512-III travel motor ensures reliable operation even in the most demanding environments. Compatible with leading brands such as Caterpillar, Komatsu, Hitachi, and Volvo, this motor is engineered to deliver smooth, consistent power transfer, improving your machine's travel capabilities and operational efficiency.

SPARKLING MACHINERY focuses not only on product quality but also on customer satisfaction. Our experienced team provides customized solutions and technical support, ensuring that the HD512-III travel motor fits perfectly within your excavator system. Dedicated consultation and continuous after-sales service make us a trusted partner in your equipment maintenance.

Choosing the SPARKLING HD512-III travel motor means opting for durability, precision engineering, and cost-effective performance. With competitive pricing and a global sales network, SPARKLING MACHINERY is proud to support your excavation projects with parts that stand the test of time.

Trust SPARKLING for stability, reliability, and innovation—your go-to source for high-quality excavator parts.

Product Images

Q&A

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

If you don’t find your answer, please E-mail us and we’ll be happy to help you out.

HD512-III 619-62500001 FINAL DRIVE ASSY 317-50201000 SPROCKET

SPARKLING MACHINERY offers a premium Final Drive Assembly (619-62500001) paired with a high-strength Sprocket (317-50201000) for the Kato HD512-III excavator. This drive system is engineered for maximum torque, reliable track propulsion, and exceptional durability under rugged working conditions.

The Final Drive Assy transmits hydraulic power to the tracks with precision and is built using high-grade gears, seals, and housings. The Sprocket, heat-treated for wear resistance, guarantees smooth engagement with the track links and long service life even in abrasive environments.

CATERPILLAR WHEEL LOADER 962 936F 960F 972G 980C 980F 270-1528 2701528 O RING KIT BOX 570PCS

The Caterpillar O‑Ring Kit (part no. 270‑1528 / 2701528) includes approximately 570 nitrile (Buna‑N) O‑rings available in 32 standard sizes, designed for use in heavy-duty Cat equipment such as wheel loaders (962, 936F, 960F, 972G, 980C, 980F) and excavators. Built to OEM specifications with 90 Durometer hardness, this kit offers reliable sealing for hydraulic fittings (SAE STOR, ORFS, Code 61/62 flanges), preventing leaks, maintaining system integrity, and significantly reducing downtime during maintenance

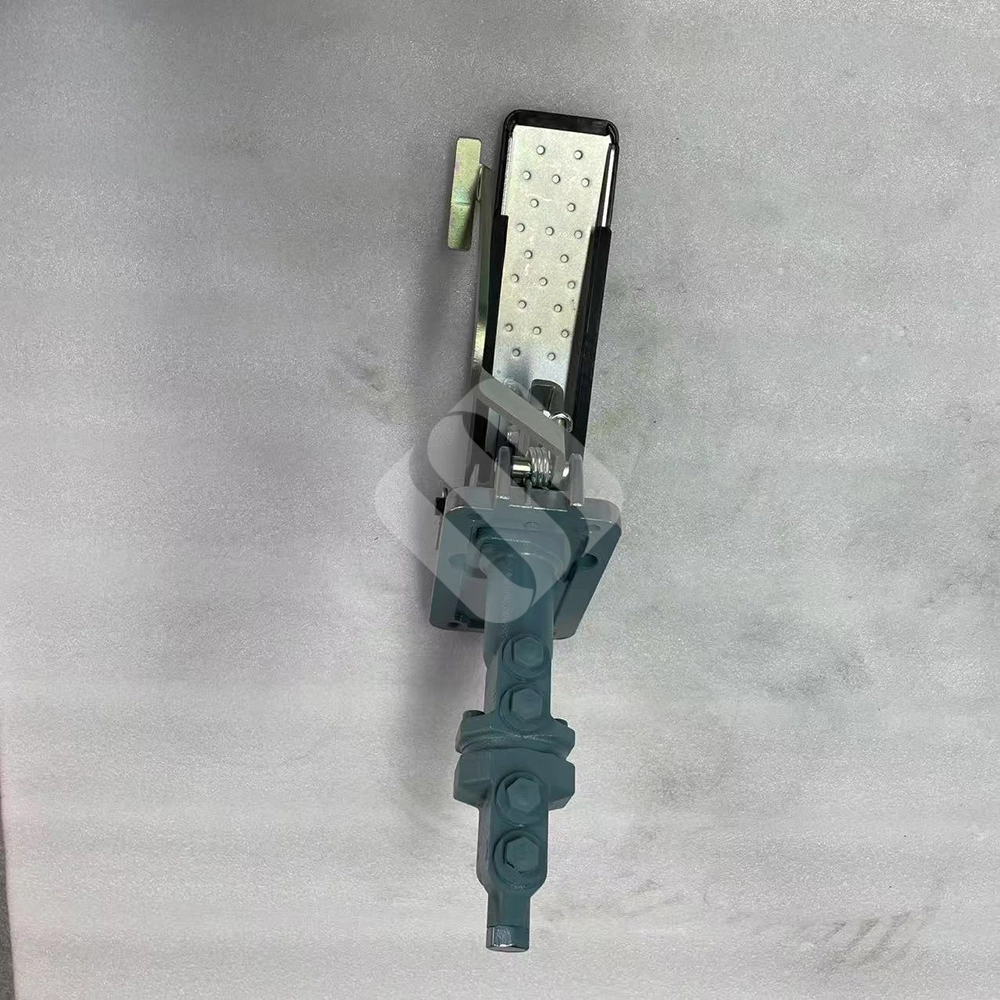

HYUNDAI WHEEL EXCAVATOR SPARE PARTS R160W9A R170W9 R170W9S R180W9A R180W9S R210W-9 BRAKE VALVE 31Q5-30110 CHINA MADE

The Hyundai 31Q5-30110 Brake Valve is a China-made replacement part designed for reliable and precise braking control in Hyundai wheel excavators, including models R160W9A, R170W9, R180W9A, and R210W-9.

31E3-3187 Accumulator for Hyundai excavators R140W-9 R170W-7 R180W-9 R210W-9 and Case E18C CX37C

The 31E3-3187 Hydraulic Accumulator is a premium diaphragm-type accumulator engineered for Hyundai wheeled excavators (R140W-9/R170W-7/R180W-9/R210W-9) and Case mini-excavators (E18C/CX37C). It stabilizes hydraulic system pressure, absorbs shock waves, and stores energy for peak-demand operations, preventing component fatigue and extending service life in high-vibration construction environments.

Key Features

· OEM-Matched Precision: 0.35L volume, 31.5MPa max working pressure, and diaphragm design for consistent pressure regulation and energy storage.

· High-Strength Construction: Carbon steel body with anti-corrosion coating and reinforced crimped end caps for 10,000+ hours service in harsh conditions.

· Leak-Proof & Shock-Absorbent: Nitrile rubber diaphragm and O-ring seals eliminate fluid leakage; absorbs pressure spikes up to 42MPa to protect valves/pumps.

· Plug-and-Play Fit: Direct bolt-on mounting with 3/4" NPT port; no modification needed for Hyundai/Case excavator installation.

Compatible Equipment

· Excavators: Hyundai R140W-9, R170W-7, R180W-9, R210W-9; Case E18C, CX37C; also fits Hyundai R200W-7, R170W-9.

· Interchangeable Part Numbers: 31E3-3187, 31MN-90680, 31E33187.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879