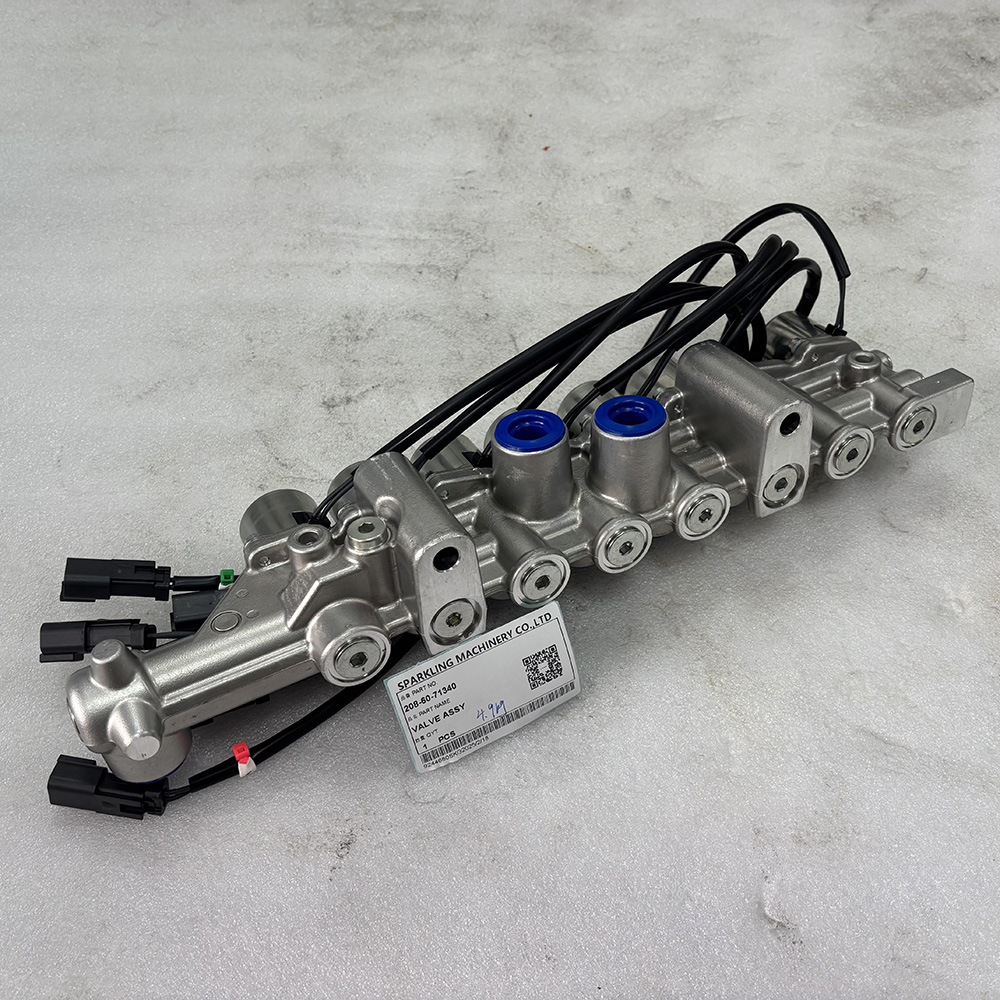

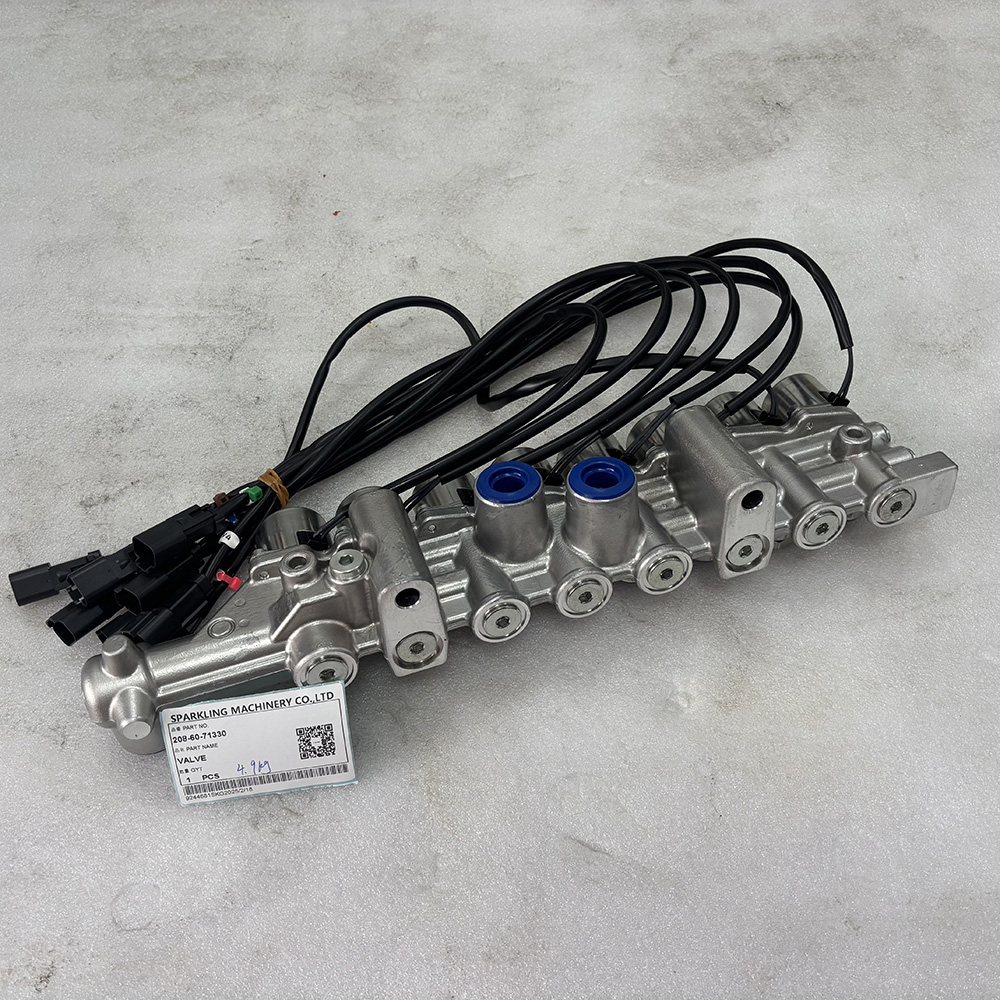

SPARKLING Solenoid Valve Assy 4.9kg – Reliable Excavator Part

The 208-60-71330 Solenoid Valve Assembly is an original quality hydraulic control component, specially designed for Komatsu PC400-7 and PC400LC-7 excavators (serial number 50001 and above). This valve plays a vital role in regulating hydraulic flow to various systems such as swing, travel, boom, arm, and breaker functions, based on electric input signals from the operator controls.

Built with high-temperature copper coils, reinforced casing, and precise valve mechanics, this solenoid valve guarantees stable performance, rapid response, and long service life in harsh working conditions. Manufactured by SPARKLING MACHINERY, it meets or exceeds OEM performance standards.

SPARKLING Solenoid Valve Assy 4.9kg – Precision and Reliability You Can Trust

SPARKLING MACHINERY, established in 2013, proudly presents the Solenoid Valve Assy 4.9kg, a High Quality hydraulic component designed to deliver exceptional performance and durability. Crafted with precision and engineered for stability, this solenoid valve assembly is ideal for a wide range of excavators, ensuring seamless operation in demanding environments.

Our Solenoid Valve Assy 4.9kg reflects SPARKLING’s commitment to quality and rigorous manufacturing processes. Compatible with leading excavator brands such as Caterpillar, Komatsu, Hitachi, and Volvo, this component meets the highest industry standards, offering users peace of mind with consistent reliability. Whether operating in harsh conditions or long-term projects, this solenoid valve maintains optimal control over hydraulic flow, reducing downtime and increasing efficiency.

SPARKLING MACHINERY goes beyond supplying parts; we provide customized solutions and expert technical support tailored to your specific needs. Our dedicated consultation services and ongoing after-sales support ensure that every customer benefits from our commitment to innovation, quality, and cost-effectiveness.

Choose the SPARKLING Solenoid Valve Assy 4.9kg for a dependable, precision-crafted hydraulic solution. With competitive prices, extensive product range, and a global sales network, SPARKLING MACHINERY is your trusted partner in excavator parts, helping you enhance productivity while reducing operational costs.

Product Images

Frequently Asked Questions

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

PC400-7 50001-UP PC400LC-7 50001-UP 208-60-71330 2086071330 SOLENOID VALVE ASSY ORIGINAL QUALITY 4.9KG

The 208-60-71330 Solenoid Valve Assembly is an original quality hydraulic control component, specially designed for Komatsu PC400-7 and PC400LC-7 excavators (serial number 50001 and above). This valve plays a vital role in regulating hydraulic flow to various systems such as swing, travel, boom, arm, and breaker functions, based on electric input signals from the operator controls.

Built with high-temperature copper coils, reinforced casing, and precise valve mechanics, this solenoid valve guarantees stable performance, rapid response, and long service life in harsh working conditions. Manufactured by SPARKLING MACHINERY, it meets or exceeds OEM performance standards.

Control GP-handle for Caterpillar M315 M317 wheeled excavator 481-9614 4819614

SPARKLING Control GP-handle 481-9614 (4819614) for Caterpillar M315 and M317 wheeled excavators ensures precise operation and durability. Engineered for CAT M315 control handle replacement, it optimizes machine performance and reliability. Compatible with models M315/M317.

The Control GP-Handle (Part No. 481-9614 / 4819614) is designed for Caterpillar wheeled excavators M315 and M317, providing precise and reliable control for excavator operation.

This control handle assembly is manufactured with durable materials and accurate internal components to ensure smooth response, comfortable operation, and long service life in demanding working environments. It is produced to meet OEM fitment and functional standards, making it a dependable replacement for original CAT control handles.

Ideal for operator control system repair and replacement, this aftermarket control GP-handle helps restore machine responsiveness and operational efficiency.

Brand: SPARKLING MACHINERY

Condition: New

Machine Models: Caterpillar M315 / M317

Part Numbers:

481-9614

4819614

Swing Motor for Volvo Excavator EC330B EC330C EC340D EC350E VOE14625697 14625697 From SPARKLING MACHINERY

SPARKLING MACHINERY NEW EC330B EC330C EC340D EC350E VOE14625697 Swing Motor is a core power component for 4 Volvo excavator models (construction/mining use). It converts hydraulic energy to mechanical power for smooth, precise upper-structure swinging—critical for heavy-load tasks.

We provide high-quality swing motor VOE14625697 for Volvo EC330B, EC330C, EC340D, and EC350E models. Sparkling Machinery ensures tested performance and fast global shipping.

Wheel Loader 423-22-32662 PLANET CARRIER FOR WA380-5 WA380-6 WA430-5 WA400-5 WA380-7 WA380-8

The 423-22-32662 planet carrier from SPARKLING MACHINERY is a durable, OEM-compatible component for Komatsu WA380 wheel loaders. Made from heat-treated alloy steel with precision-machined teeth, it ensures reliable power transmission in tough job sites. Fast global shipping and factory pricing are available.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879