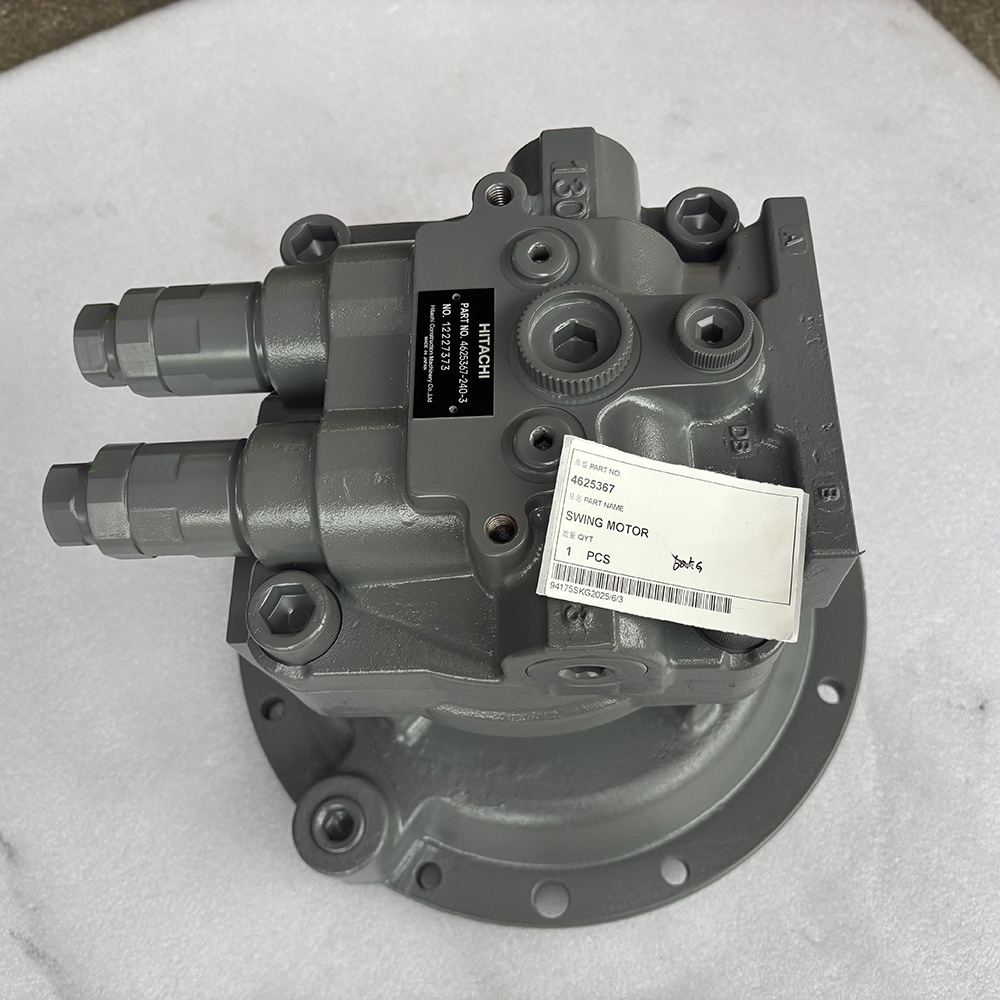

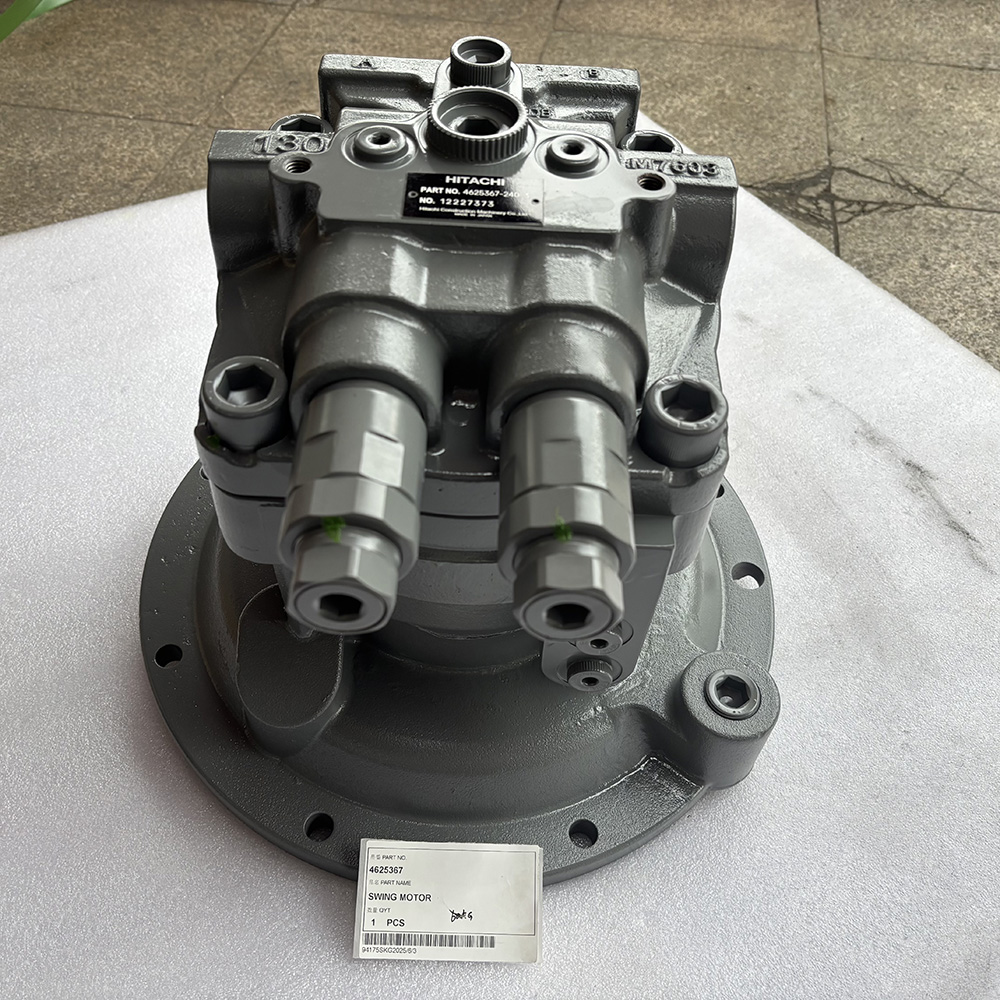

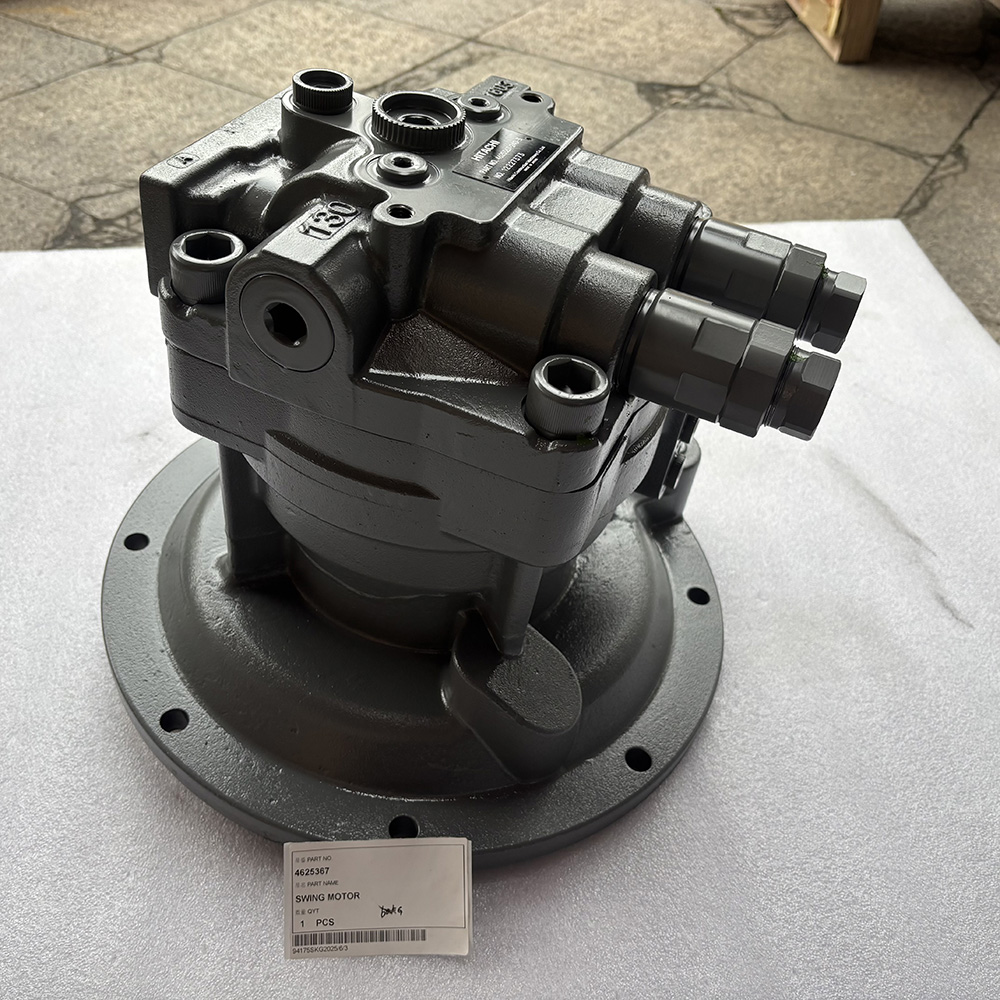

SPARKLING ZX240-5G Rotation Motor – Durable Excavator Part

Hydraulic Swing Motor Assembly 4625367 for Hitachi ZX240-3, ZX240-5G, ZX250H-3, ZX250H-3G, ZX250H-5G Excavators

The 4625367 Hydraulic Swing Motor Assembly is a high-performance OEM-compatible replacement designed for Hitachi ZX240 and ZX250H series excavators. As a crucial part of the upper-structure slewing system, it transforms hydraulic energy into mechanical rotation, enabling smooth and controlled 360-degree movement of the cab and boom.

Manufactured by SPARKLING MACHINERY, this swing motor offers excellent torque, smooth operation, and long service life, making it ideal for demanding earthwork and construction applications. It is fully tested for performance, ensuring a direct-fit solution with zero leakage and superior durability.

SPARKLING ZX240-5G Rotation Motor – Precision and Durability for Excavators

Introducing the SPARKLING ZX240-5G rotation motor, a High Quality component designed to enhance the performance and reliability of your excavator. Manufactured by SPARKLING MACHINERY, a trusted name since 2013, this rotation motor combines stability, precision, and durability to ensure seamless operation in demanding conditions.

Specifically engineered for ZX240-5G models, this rotation motor delivers smooth, consistent rotational power that maximizes machine efficiency and reduces downtime. Built with high-quality materials and subjected to rigorous quality control, it maintains excellent resistance to wear and tear, providing you with a long service life. Whether working on heavy excavation, lifting, or rotating tasks, the ZX240-5G rotation motor supports optimal power transmission and control, improving overall job site productivity.

As part of SPARKLING MACHINERY’s extensive range of excavator parts—including hydraulic components, undercarriage systems, engine components, electrical parts, and cabs—this rotation motor qualifies for compatibility with top industry brands such as Caterpillar, Komatsu, Hitachi, and Volvo. We understand that every job requires reliable equipment; therefore, we offer tailored technical support and customization options to meet your unique requirements.

At SPARKLING, we prioritize customer satisfaction by combining competitive pricing with uncompromising quality. Our global sales network ensures you have access to timely delivery and ongoing service, helping you reduce operational costs without sacrificing performance. Trust the ZX240-5G rotation motor from SPARKLING to empower your excavator with dependable rotation power, so you can focus on what matters most—getting the job done efficiently and safely.

Product Image

Question you may concern

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

ZX240-3 ZX240-5G ZX250H-3 ZX250H-3G ZX250H-5G 4625367 HYDRAULIC SWING MOTOR ASSY

Hydraulic Swing Motor Assembly 4625367 for Hitachi ZX240-3, ZX240-5G, ZX250H-3, ZX250H-3G, ZX250H-5G Excavators

The 4625367 Hydraulic Swing Motor Assembly is a high-performance OEM-compatible replacement designed for Hitachi ZX240 and ZX250H series excavators. As a crucial part of the upper-structure slewing system, it transforms hydraulic energy into mechanical rotation, enabling smooth and controlled 360-degree movement of the cab and boom.

Manufactured by SPARKLING MACHINERY, this swing motor offers excellent torque, smooth operation, and long service life, making it ideal for demanding earthwork and construction applications. It is fully tested for performance, ensuring a direct-fit solution with zero leakage and superior durability.

Valve GP‑Manual 389‑2407 for Cat 352 / 323F / 320C / 320D / M325D / 355 Excavators

The Valve GP‑Manual (Cat part no. 389‑2407 / CA3892407) is a rugged manual auxiliary shut‑off valve designed for use in heavy-duty Caterpillar excavators—specifically models 352, 323F, 320C, 320D SA, M325D MH/L, 355, and more. It provides dependable two-way hydraulic shut-off control, helping protect critical systems during maintenance or attachments handling. Built to OEM tolerance, this valve ensures reliable operation in the harshest environments, available both as a genuine Cat part and high-quality aftermarket alternative.

Case MADE IN CHINA SPARKLING MACHINERY NEW LC00159 GEAR BOX

SPARKLING MACHINERY NEW LC00159 Gear Box is a premium China-made power transmission component designed for compatible construction machinery, including wheel loaders, excavators, and compact utility vehicles. As the "power distribution core" of the machinery’s drivetrain, it converts and transmits torque from the engine to the wheels or working mechanisms (e.g., bucket lifts, arm rotations), enabling smooth speed adjustment and torque amplification. This ensures the machinery delivers optimal power for diverse tasks—such as heavy material hauling, site leveling, and precision lifting—in construction, agriculture, and warehouse logistics scenarios.

Engineered to original equipment standards, it maintains stable transmission performance even under harsh working conditions: high torque loads, continuous vibration, dust ingress, and temperature fluctuations (-25°C to 90°C). With precision-machined gears (for minimal friction) and a sealed lubrication system (to prevent oil leakage), it minimizes wear and extends component life. Backed by strict quality verification, it guarantees reliable power transfer to support uninterrupted machinery operation and reduce downtime caused by drivetrain failures.

HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 4472-319-2158&4472-322-012 GEAR-SUN&CARRIER DISC SPARKLING MACHINERY

SPARKLING MACHINERY NEW 4472-319-2158&4472-322-012 Gear-Sun&Carrier Disc is a core transmission component for excavators (heavy-duty construction/mining use). It works with planetary gear systems to adjust speed and amplify torque, ensuring smooth power transfer.

Meeting high OEM standards, it resists -30°C to 100°C temps, wear, and mechanical shock, ensuring seamless compatibility with multiple models and long-term reliable transmission performance.

Sparkling Machinery Co.,Ltd

foreverlucia1