SPARKLING 1210E Sensor – Reliable Excavator Component

The John Deere Temperature Sensor (RE522823) is a vital engine and hydraulic monitoring component for mid-to-large John Deere equipment—optimizing operational safety across models like the 1210E, 670G, 290GLC, 755D, 624K, 350DLC, and 953M. Engineered for precise temperature measurement, this two-terminal sensor ensures accurate data feedback to prevent overheating and protect critical engine components. Built to meet or exceed OEM standards, it delivers reliable performance in rugged environments.

SPARKLING 1210E Sensor: Precision and Reliability You Can Trust

At SPARKLING MACHINERY, founded in 2013, we specialize in delivering high-quality excavator parts designed for stability, precision, and durability. Among our High Quality products, the 1210E sensor stands out as a vital component engineered to enhance excavator performance and operational reliability. Compatible with leading excavator brands such as Caterpillar, Komatsu, Hitachi, and Volvo, the 1210E sensor ensures seamless integration and exceptional functionality under demanding working conditions.

Manufactured through rigorous quality control processes, the 1210E sensor provides accurate and consistent data, enabling precise control and monitoring of excavator operations. This sensor plays a crucial role in improving machine efficiency, reducing downtime, and enhancing safety on site. Whether you operate mini excavators or heavy-duty machinery, SPARKLING’s 1210E sensor offers dependable performance you can count on.

Our commitment to innovation and customer satisfaction means we offer tailored solutions and ongoing technical support, ensuring optimal use of the 1210E sensor. With competitive pricing and a comprehensive global sales network, SPARKLING MACHINERY is your trusted partner for all excavator component needs. Choose SPARKLING’s 1210E sensor for a reliable, professional, and cost-effective solution to maximize your excavator’s capabilities.

Detailed display

Question you may concern

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

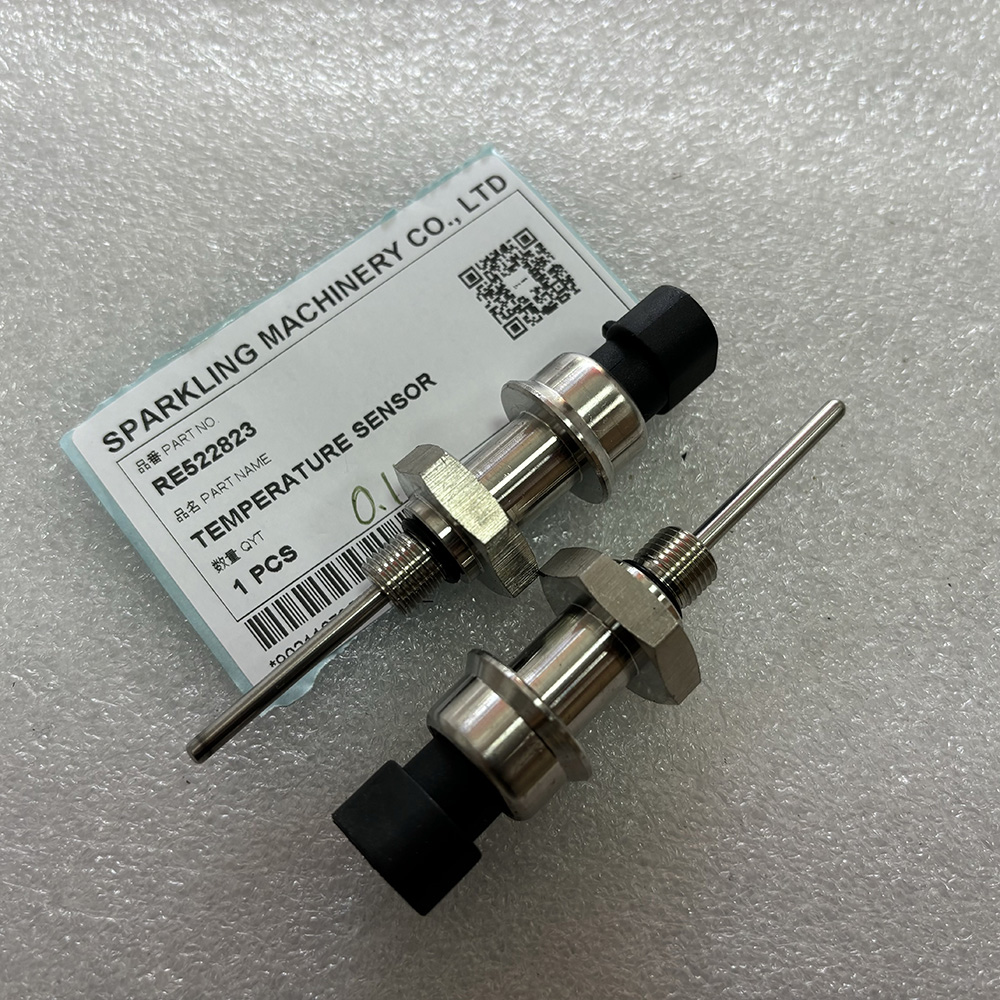

John Deere Temperature Sensor RE522823 – Fits 1210E • 670G • 290GLC • 755D • 624K • 350DLC • 953M

The John Deere Temperature Sensor (RE522823) is a vital engine and hydraulic monitoring component for mid-to-large John Deere equipment—optimizing operational safety across models like the 1210E, 670G, 290GLC, 755D, 624K, 350DLC, and 953M. Engineered for precise temperature measurement, this two-terminal sensor ensures accurate data feedback to prevent overheating and protect critical engine components. Built to meet or exceed OEM standards, it delivers reliable performance in rugged environments.

CATERPILLAR BACKHOE LOADER 414E 416D 420D 420E 422E 424D 428D CA2341981 234-1981 2341981 AIR CLEANER GP

The CA2341981 Air Cleaner GP is a genuine-quality replacement component designed to deliver optimal engine protection for Caterpillar backhoe loaders. Built for heavy-duty performance, this air cleaner ensures that your machine breathes clean air even in the harshest worksite conditions, extending engine life and improving overall fuel efficiency.

🔧 Features:

-

OEM-quality construction with durable filtration materials

-

Perfect fit for Caterpillar models 414E, 416D, 420D, 420E, 422E, 424D, 428D

-

Efficient particle separation and low airflow restriction

-

Easy installation and maintenance

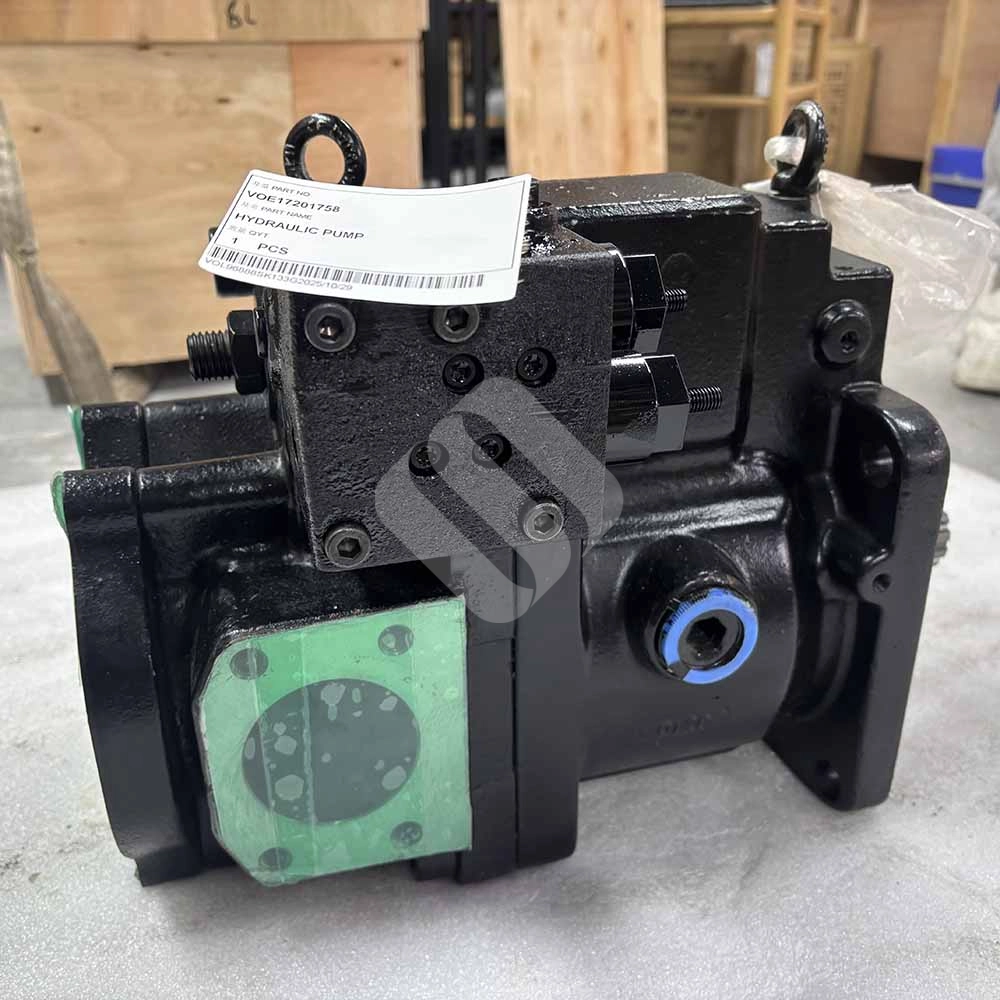

Hydraulic Pump For Volvo L150G L150H L180G L180H VOE17201758 17201758 From Sparkling Machinery

SPARKLING MACHINERY NEW L150G L150H L180G L180H VOE17201758 Hydraulic Pump is a core power component for 4 Volvo wheel loader models (heavy-duty construction/mining use). It converts mechanical energy to stable hydraulic pressure, driving lifting, loading, and steering systems for high-intensity tasks.

Meeting Volvo OEM standards (VOE17201758), it resists -30°C to 100°C temps, high pressure, and wear, guaranteeing seamless compatibility and long-term reliable hydraulic performance.

Denso ND029600-0580 Sensor Compatible with Komatsu PC450-7 Excavator | SA6D140E & SAA6D140E Engines

The Denso ND029600-0580 sensor is a high-precision monitoring component tailored for Komatsu PC450-7 excavators and SA6D140E/SAA6D140E engines.

Key Features

· High-precision detection for reliable engine parameter monitoring (e.g., pressure, temperature, position)

· Stable signal transmission with strong anti-interference performance for complex working environments

· Direct OEM fit matching Komatsu’s original specifications for seamless integration

· Durable construction to withstand vibration, dust, and extreme temperature variations (-20°C to 80°C)

· Easy installation to minimize equipment downtime during replacement

Compatible Models

· Komatsu excavator: PC450-7 excavator.

· Komatsu engines: SA6D140E, SAA6D140E, SDA6D140E, and SA6D125E series.

· Hino engines, specifically J08C and J05C models.

· Interchangeable Part Numbers: ND029600-0580 (Denso original specification matching)

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879