SPARKLING 290GLC Sensor – Reliable Excavator Monitoring Part

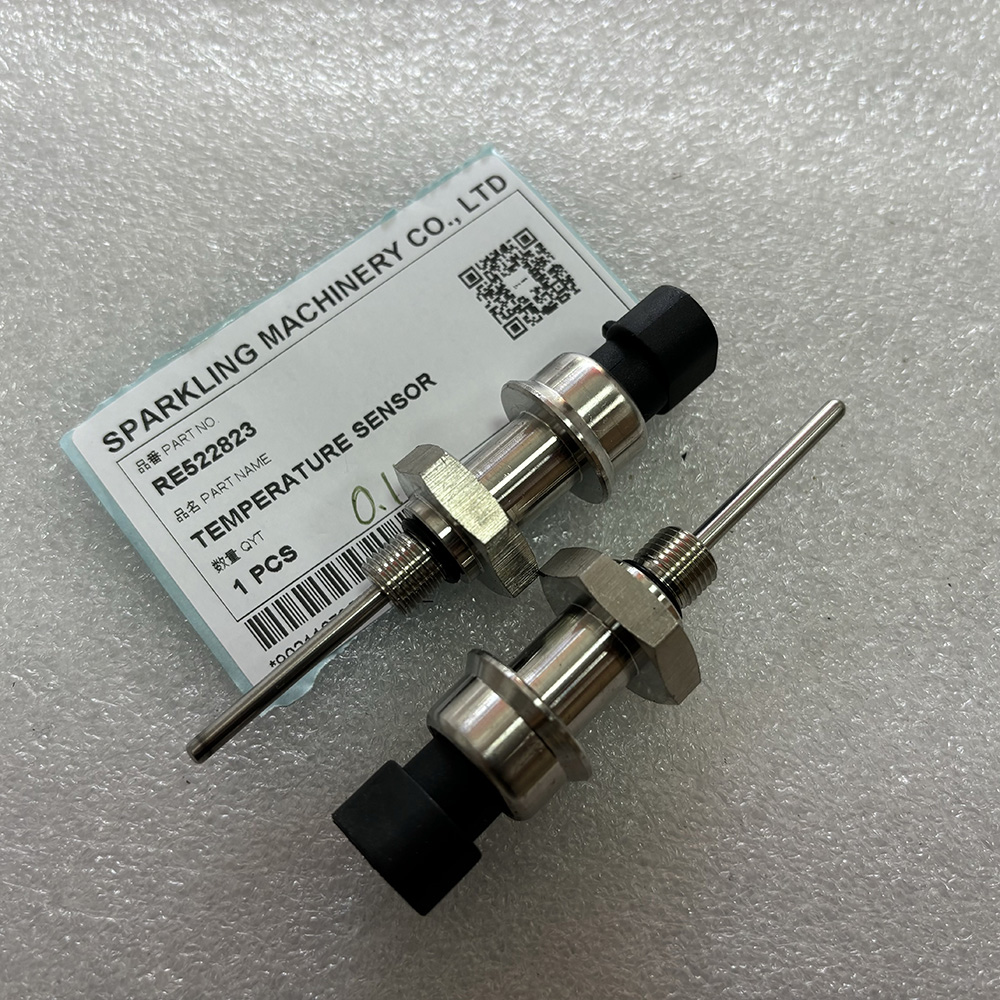

The John Deere Temperature Sensor (RE522823) is a vital engine and hydraulic monitoring component for mid-to-large John Deere equipment—optimizing operational safety across models like the 1210E, 670G, 290GLC, 755D, 624K, 350DLC, and 953M. Engineered for precise temperature measurement, this two-terminal sensor ensures accurate data feedback to prevent overheating and protect critical engine components. Built to meet or exceed OEM standards, it delivers reliable performance in rugged environments.

SPARKLING 290GLC Sensor – Precision and Reliability for Your Excavator

At SPARKLING MACHINERY, founded in 2013, we specialize in delivering high-quality excavator parts that combine stability, precision, and durability. Our 290GLC sensor exemplifies our commitment to excellence, designed specifically to meet the demanding performance needs of modern excavators like Caterpillar, Komatsu, Hitachi, and Volvo.

The SPARKLING 290GLC sensor ensures accurate and reliable monitoring of your excavator’s operational status, helping to optimize performance and extend equipment lifespan. Engineered with strict quality control standards, this sensor functions flawlessly in various harsh environments, maintaining dependable output whether you are working in extreme temperatures, dusty environments, or intense vibrations.

We understand how critical component reliability is to your construction projects; that’s why the 290GLC sensor undergoes rigorous testing to guarantee stable operation and precise data feedback. Its easy installation and compatibility with multiple leading excavator brands make it a practical choice for maintenance teams seeking efficiency and cost savings.

Beyond product quality, SPARKLING offers personalized technical support and customized solutions to make sure you get the right part the first time around. Our global distribution network ensures timely delivery and ongoing service, reflecting our dedication to your success.

Choose the SPARKLING 290GLC sensor to benefit from advanced technology, continuous innovation, and a trusted partner who values your equipment’s health as much as you do. Experience the difference that precision and perseverance bring to your excavator parts needs.

Product Images

FAQ

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

John Deere Temperature Sensor RE522823 – Fits 1210E • 670G • 290GLC • 755D • 624K • 350DLC • 953M

The John Deere Temperature Sensor (RE522823) is a vital engine and hydraulic monitoring component for mid-to-large John Deere equipment—optimizing operational safety across models like the 1210E, 670G, 290GLC, 755D, 624K, 350DLC, and 953M. Engineered for precise temperature measurement, this two-terminal sensor ensures accurate data feedback to prevent overheating and protect critical engine components. Built to meet or exceed OEM standards, it delivers reliable performance in rugged environments.

3Kg 719754 EPPR Valve for Doosan DX225 & SL150LC-V Excavators – Reliable Replacement Part

719754 EPPR Valve (3kg) is a core electro-hydraulic control component for Doosan DX225/SL150LC-V excavators. Mounted on the main hydraulic pump, it adjusts pilot pressure via CPU signals to regulate pump flow, prevent engine stall, ensure smooth operation and optimize hydraulic efficiency.

Function: The valve consists of an electromagnet and a spool valve installed in the main hydraulic pump. It receives an electric current from the machine's controller and moves the spool proportionally to this signal. This action regulates the pilot pressure to the hydraulic pump's flow regulator, which in turn decreases the main pump flow to match the engine load and operator demand.

Compatible Equipment: In addition to the Doosan DX225, this valve is used in models like the R210LC-7, R225-7, R215-7, R140LC9-S, and others.

021111435 GOVERNOR CONTROLLER

The 021111435 Governor Controller is a high-precision electronic control unit designed to regulate engine speed and optimize fuel efficiency in heavy machinery such as excavators, loaders, and other diesel-powered equipment.

Built to withstand harsh jobsite environments, this controller offers precise throttle response, stable speed regulation, and fault tolerance, ensuring smooth operation, lower emissions, and extended engine life. Whether you're replacing a faulty unit or upgrading your engine control system, this governor controller is a reliable and cost-effective solution.

Compatible with a wide range of construction equipment, it is easy to install and integrates seamlessly into your machine’s electronic control system.

JS220 JS200 JS220LR JS210 JS235 JRC0007 SWING GEAR BOX REDUCER

Heavy-Duty Swing Gearbox Reducer for Hitachi JS Excavators

Engineered for JS200, JS210, JS220, JS220LR, and JS235 excavators, the Swing Gearbox Reducer (JRC0007) is the precision heart of your machine’s rotation system. This OEM-compatible reducer delivers unmatched torque transmission and smooth 360° slewing motion under extreme loads. Forged with hardened helical gears and triple-sealed bearings, it resists wear, minimizes backlash, and withstands relentless job site vibrations. SPARKLING MACHINERY’s JRC0007 undergoes rigorous cycle testing to ensure perfect meshing alignment and extended service life – because precise rotation isn’t a luxury, it’s the core of your excavator’s productivity.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879