SPARKLING 350DLC Engine Monitor – Precision Excavator Engine Monitoring

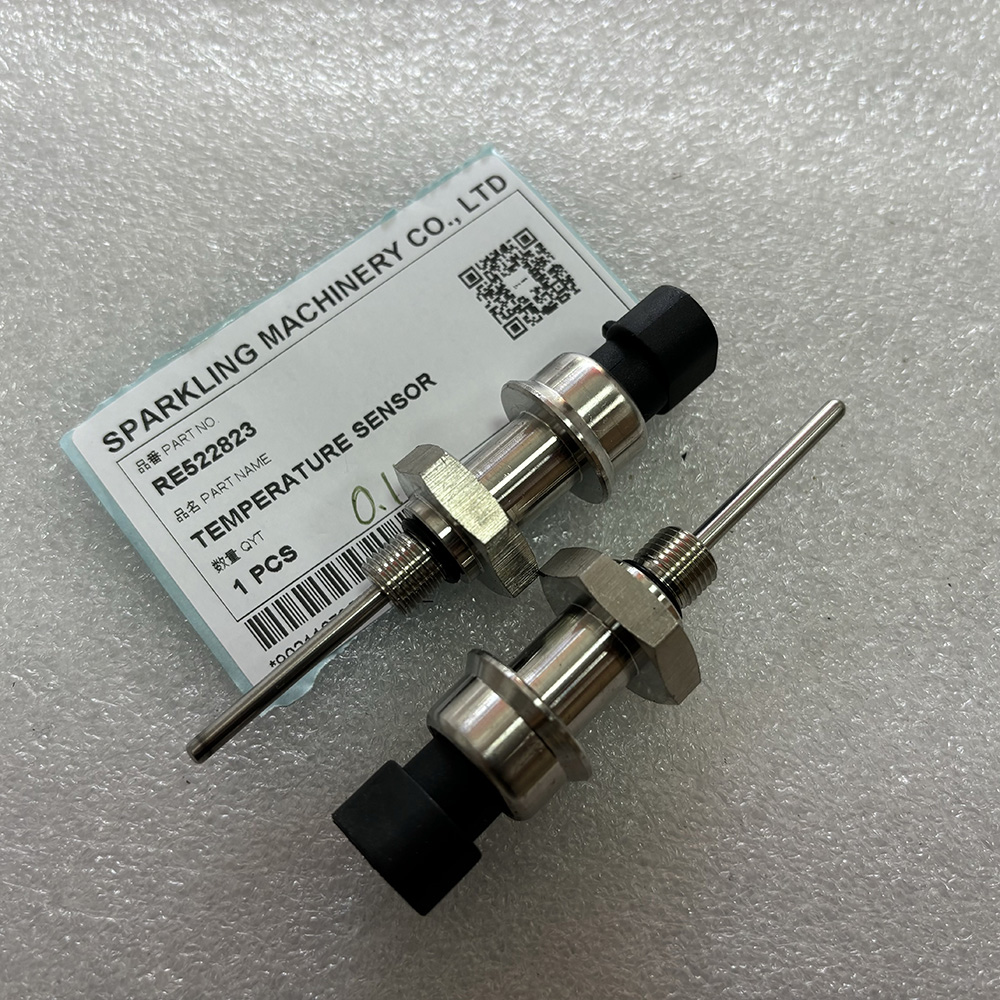

The John Deere Temperature Sensor (RE522823) is a vital engine and hydraulic monitoring component for mid-to-large John Deere equipment—optimizing operational safety across models like the 1210E, 670G, 290GLC, 755D, 624K, 350DLC, and 953M. Engineered for precise temperature measurement, this two-terminal sensor ensures accurate data feedback to prevent overheating and protect critical engine components. Built to meet or exceed OEM standards, it delivers reliable performance in rugged environments.

SPARKLING 350DLC Engine Monitor: Precision and Reliability for Your Excavator

At SPARKLING MACHINERY, we understand that the performance and durability of your excavator depend on every component working seamlessly together. Our 350DLC engine monitor is designed with stability and precision in mind, offering real-time insights into your engine’s vital parameters to maximize efficiency and minimize downtime.

Compatible with leading excavator brands like Caterpillar, Komatsu, Hitachi, and Volvo, the SPARKLING 350DLC engine monitor delivers accurate data on temperature, oil pressure, fuel levels, and engine speed, ensuring you can detect potential issues early and maintain optimal operation. Manufactured under strict quality control, this monitor withstands harsh working environments, providing you with reliable performance every time.

Beyond its robust functionality, the 350DLC engine monitor from SPARKLING supports customized settings tailored to your specific equipment needs. Our expert technical support team is always ready to help with installation guidance, troubleshooting, and personalized consultation – because we value your investment as much as you do.

Choosing SPARKLING means you get high-quality excavator parts at competitive prices, backed by a company dedicated to innovation, perseverance, and customer care. Reduce your maintenance costs and improve the lifespan of your machinery with our trusted 350DLC engine monitor, your dependable partner in the field.

Detailed display

Q&A

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

John Deere Temperature Sensor RE522823 – Fits 1210E • 670G • 290GLC • 755D • 624K • 350DLC • 953M

The John Deere Temperature Sensor (RE522823) is a vital engine and hydraulic monitoring component for mid-to-large John Deere equipment—optimizing operational safety across models like the 1210E, 670G, 290GLC, 755D, 624K, 350DLC, and 953M. Engineered for precise temperature measurement, this two-terminal sensor ensures accurate data feedback to prevent overheating and protect critical engine components. Built to meet or exceed OEM standards, it delivers reliable performance in rugged environments.

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EC140D EC140E EC160E EC180E EC220D VOE14675537 WIPER MOTOR SPARKLING MACHINERY

SPARKLING MACHINERY NEW EC140D EC140E EC160E EC180E EC220D VOE14675537 Wiper Motor is a dedicated cab safety component for VOLVO EC140D, EC140E, EC160E, EC180E, and EC220D crawler excavators (widely used in construction, municipal engineering, and medium-scale mining). As a core part of the excavator’s cab visibility system, it drives the wiper blade to clear rain, snow, or dust from the front windshield—ensuring unobstructed vision for operators during tasks like digging, loading, and equipment maneuvering, thus enhancing operational safety.

Meeting VOLVO OEM standards (part no. VOE14675537), it endures -30°C to 85°C temperatures, resists vibration and moisture, and maintains stable rotational speed. Strict testing guarantees seamless compatibility with the five VOLVO models and long-term reliable wiping performance.

VOLVO MADE IN CHINA SPARKLING MACHINERY NEW EC290B EC290C FC3329C VOE14598751 SWING MOTOR

SPARKLING MACHINERY NEW VOE14598751 Swing Motor, a high-quality China-made core hydraulic component for excavators, is engineered to deliver reliable rotational power for smooth 360° slewing of the upper structure. Built to original equipment standards, it ensures seamless compatibility with compatible excavator models, making it an ideal replacement part for construction, mining, and earthmoving operations.

Crafted from high-strength alloy materials with precision-machined internal components, this swing motor withstands high pressure and heavy loads while maintaining stable performance. Equipped with advanced hydraulic control technology and multi-layer sealing systems, it achieves excellent resistance to dust, water, and leakage, adapting to harsh working environments. Backed by strict quality testing and professional technical support, it guarantees long-term operational efficiency, minimizing downtime and maximizing equipment productivity.

147-1446 Plug for Caterpillar Wheel Loaders 950H 966H & Wheel Tractor-Scrapers 621 623K

The 147-1446 Plug is a 70-pin sealed female electrical wiring connector, a critical signal transmission component for the main control harness of Caterpillar wheel loaders 950H/966H and wheel tractor-scrapers 621/623K. It connects the machine’s electronic control module (ECM) to the wiring harness, ensuring stable communication between the engine, transmission, and hydraulic systems.

Key Features

· OEM-Matched Precision: 70-pin configuration and exact housing dimensions for Cat models—no wiring modification needed.

· Sealed & Durable: PBT+GF housing with IP67-rated sealing; terminal made of brass/phosphor bronze for anti-corrosion and conductivity.

· Wide Temperature Range: Operates at -40°C to 120°C, adapting to extreme working conditions.

· Plug-and-Play Installation: Pre-crimped terminals and locking mechanism for quick, secure fitting; reduces replacement time to 45 minutes.

Compatible Equipment

· Wheel Loaders: Caterpillar 950H, 966H, 966H II, 972H, 980H.

· Wheel Tractor-Scrapers: Caterpillar 621, 623K, 627K, 631K, 633K.

· Track-Type Tractors: D6T, D8T, D9T, D11.

· Interchangeable Part Numbers: 147-1446, 1471446, 147-1446X, 147-1446-001.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879