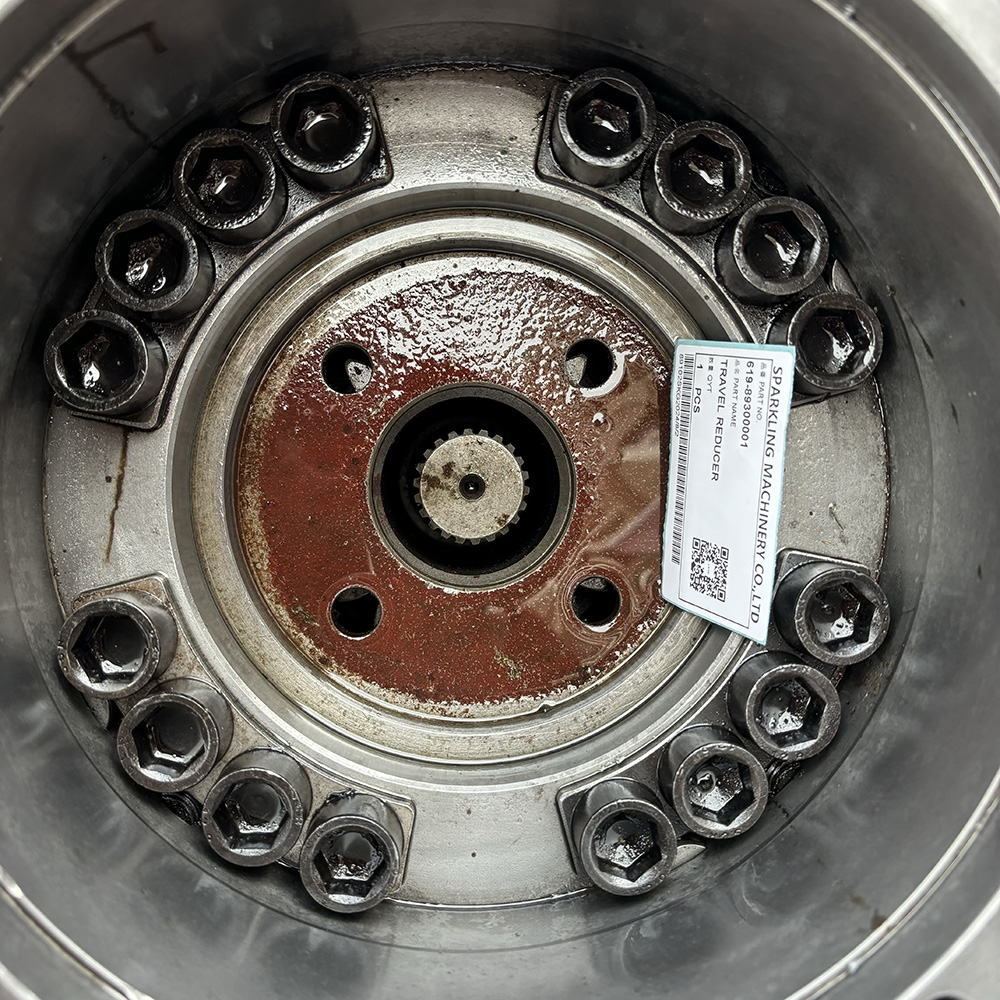

SPARKLING 619-89300001 Hydraulic Reducer – Reliable Excavator Part

The KATO HD1430 619-89300001 Hydraulic Travel Reducer is a robust and high-performance final drive component, specially engineered for KATO HD1430 crawler excavators. It delivers powerful torque conversion and reliable speed reduction, essential for smooth and efficient machine mobility under heavy-duty conditions. Manufactured with high-precision parts and advanced sealing systems, this travel reducer ensures durability, minimal leakage, and long service life—perfectly matching OEM specifications. Ideal for both replacements and maintenance operations, it guarantees stable performance across various terrains and job sites.

Discover the SPARKLING 619-89300001 Hydraulic Reducer, a vital component engineered for exceptional performance and durability in excavator hydraulic systems. Crafted with precision and built to last, this hydraulic reducer optimizes hydraulic flow efficiency, ensuring smooth operation and enhanced power transmission. Ideal for heavy-duty applications, it guarantees stability and reliability across various working conditions.

Since 2013, SPARKLING MACHINERY has been dedicated to manufacturing high-quality excavator parts, earning a reputation for stability, precision, and perseverance. The 619-89300001 hydraulic reducer exemplifies our commitment to superior craftsmanship and rigorous quality control. Compatible with leading brands like Caterpillar, Komatsu, Hitachi, and Volvo, this reducer fits seamlessly into your excavator’s hydraulic system, enhancing performance and reducing downtime.

What sets the SPARKLING 619-89300001 apart is its robust construction combined with cutting-edge technology, designed to withstand high stress and corrosive environments. Our hydraulic reducer not only improves hydraulic efficiency but also contributes to lowering maintenance costs over time. With SPARKLING’s customized solutions and dedicated technical support, you receive a product backed by expertise and continuous service—helping you maximize operational uptime and reduce overall expenses.

Choose the SPARKLING 619-89300001 Hydraulic Reducer to benefit from a trusted partner in excavator components, offering competitive pricing without compromising quality. Elevate your machinery’s performance with SPARKLING, the industry leader committed to innovation, reliability, and customer satisfaction worldwide.

Detailed display

Q&A

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

If you don’t find your answer, please E-mail us and we’ll be happy to help you out.

KATO HD1430 619-89300001 HYDRAULIC TRAVEL REDUCER FINAL DRIVE ASSY SPARKLING MACHINERY

The KATO HD1430 619-89300001 Hydraulic Travel Reducer is a robust and high-performance final drive component, specially engineered for KATO HD1430 crawler excavators. It delivers powerful torque conversion and reliable speed reduction, essential for smooth and efficient machine mobility under heavy-duty conditions. Manufactured with high-precision parts and advanced sealing systems, this travel reducer ensures durability, minimal leakage, and long service life—perfectly matching OEM specifications. Ideal for both replacements and maintenance operations, it guarantees stable performance across various terrains and job sites.

VOLVO MADE IN CHINA SPARKLING MACHINERY NEW EC220D EC235D VOE14603650 PUMP

SPARKLING MACHINERY NEW VOE14603650 Pump, a premium China-made hydraulic core component, serves as a critical power transmission unit for excavators, delivering stable hydraulic pressure to drive key operational functions like arm movement, bucket operation, and lifting. Engineered to original equipment standards, it ensures seamless compatibility with compatible excavator models, making it an ideal replacement for construction, mining, and heavy-duty applications.

Crafted from high-strength alloy materials with precision-machined internal components, this pump withstands high pressure and continuous heavy loads while maintaining consistent performance. Equipped with advanced hydraulic regulation technology and multi-layer sealing systems, it minimizes leakage and resists dust, water, and debris intrusion, adapting to harsh working environments. Backed by strict quality testing and professional support, it guarantees long-term reliability, reducing downtime and maximizing equipment productivity.

HYUNDAI ZGAQ-01634 Bearing Lining Kit | HL770-7A HL770-9 HL780-9A HL780-3A Loader Parts

The ZGAQ-01634 Bearing Lining Kit is a genuine, high-performance repair component specifically designed for HYUNDAI wheel loaders, including models HL770-7A, HL770-9, HL780-9A, and HL780-3A.

This bearing lining kit is used in the engine or transmission system to reduce friction between rotating parts and ensure smooth, reliable operation under heavy loads. Manufactured to OEM standards, it offers excellent wear resistance, precise fitment, and long-lasting durability — making it an essential component for regular maintenance and engine rebuilds.

Whether you're performing preventive maintenance or full engine overhauls, the ZGAQ-01634 bearing kit helps restore optimal machine performance, extend equipment lifespan, and minimize downtime on the jobsite.

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EC140C EC140D EC160C EC160E 14534865 SEAL KIT SPARKLING MACHINERY

SPARKLING MACHINERY NEW EC140C EC140D EC160C EC160E 14534865 Seal Kit is a dedicated, all-in-one sealing solution exclusively engineered for VOLVO EC140C, EC140D, EC160C, and EC160E excavators—core equipment in construction, mining, and large-scale infrastructure projects. As a critical protective component for the excavators’ hydraulic systems, it covers key areas such as hydraulic cylinder rods, valve connections, and pump interfaces, forming robust leakproof barriers. This function is vital for maintaining stable hydraulic pressure, ensuring smooth and responsive operation of core mechanisms (boom lifting, arm digging, bucket tilting), and preventing dust or debris from contaminating internal hydraulic parts. It directly reduces the risk of hydraulic system failures, avoids unplanned downtime, and eliminates costly repairs caused by oil leaks during high-intensity tasks like deep excavation, bulk material loading, and site grading.

Engineered to meet VOLVO’s original equipment standards, the seal kit maintains reliable sealing performance even under harsh conditions: high hydraulic pressure (up to 36 MPa), extreme temperature fluctuations (-25°C to 105°C), and continuous excavator vibration. It resists oil aging and material wear, providing long-lasting protection for the excavators’ hydraulic systems. Backed by strict performance verification, it guarantees uninterrupted sealing support for EC140C/EC140D/EC160C/EC160E excavators.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879