SPARKLING 624K Hydraulic Sensor

The John Deere Temperature Sensor (RE522823) is a vital engine and hydraulic monitoring component for mid-to-large John Deere equipment—optimizing operational safety across models like the 1210E, 670G, 290GLC, 755D, 624K, 350DLC, and 953M. Engineered for precise temperature measurement, this two-terminal sensor ensures accurate data feedback to prevent overheating and protect critical engine components. Built to meet or exceed OEM standards, it delivers reliable performance in rugged environments.

SPARKLING 624K Hydraulic Sensor – Precision and Reliability You Can Trust

Introducing the SPARKLING 624K hydraulic sensor, a breakthrough in excavator component technology designed to deliver unmatched accuracy and durability. Developed by SPARKLING MACHINERY, a trusted name since 2013 in high-quality excavator parts, this sensor stands out by combining cutting-edge engineering with rigorous quality control to support your heavy machinery’s optimal performance.

Built for compatibility with leading brands like Caterpillar, Komatsu, Hitachi, and Volvo, the 624K hydraulic sensor excels in measuring hydraulic pressure with exceptional precision, ensuring stable and efficient operation under the toughest conditions. Its robust design resists wear, vibrations, and extreme environments, extending your equipment’s lifespan and minimizing downtime.

What sets the SPARKLING 624K hydraulic sensor apart is not only its superior performance but also the unmatched commitment behind it. SPARKLING MACHINERY provides customized solutions and technical support, ensuring easy installation and seamless integration into your existing systems. This sensor is an ideal choice for contractors and operators seeking reliability, cost efficiency, and top-tier service.

Thanks to SPARKLING’s rigorous manufacturing standards and focus on perseverance and stability, the 624K sensor brings peace of mind to your projects — accurate readings, reduced maintenance, and enhanced productivity. Choose SPARKLING’s 624K hydraulic sensor to harness precision engineering tailored for excellence in the excavator industry.

Product Images

FAQ

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

If you have any questions or concern, please contact us.

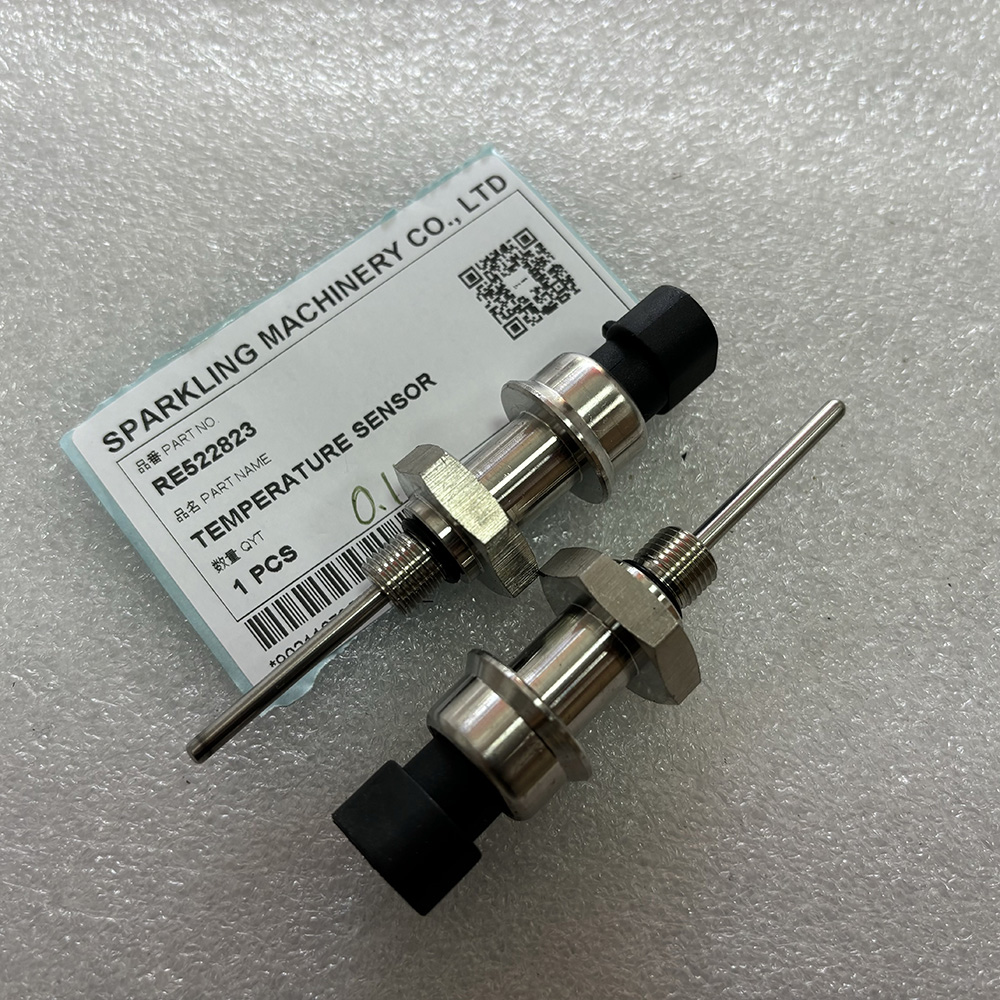

John Deere Temperature Sensor RE522823 – Fits 1210E • 670G • 290GLC • 755D • 624K • 350DLC • 953M

The John Deere Temperature Sensor (RE522823) is a vital engine and hydraulic monitoring component for mid-to-large John Deere equipment—optimizing operational safety across models like the 1210E, 670G, 290GLC, 755D, 624K, 350DLC, and 953M. Engineered for precise temperature measurement, this two-terminal sensor ensures accurate data feedback to prevent overheating and protect critical engine components. Built to meet or exceed OEM standards, it delivers reliable performance in rugged environments.

Volvo EW180E Die-Cast Excavator Model – High-Detail Metal Alloy Replica

The Volvo EW180E die-cast excavator model is a high-precision replica of the Volvo EW180E wheeled excavator. Constructed with a metal alloy body, it accurately reproduces the articulated boom, hydraulic cylinders, operator cabin, undercarriage, and wheel assemblies of the real machine.

The boom, arm, and bucket are fully movable, allowing realistic demonstration of digging and maneuvering actions. Detailed components include articulated wheels, cabin interior, handrails, and Volvo-style decals and paint finish, giving the model a highly authentic appearance.

This model is ideal for:

-

Construction machinery collector displays

-

Dealer and distributor showrooms

-

Promotional and corporate gifts

-

Engineering machinery training demonstrations

-

Volvo machinery enthusiasts

SPARKLING MACHINERY provides a full range of construction machinery models, including excavators, wheel loaders, compactors, articulated haulers, bulldozers, and more, covering brands such as CAT, Komatsu, Volvo, Kobelco, SANY, Shantui, Hitachi, Hyundai Doosan and more.

The Volvo EW180E model combines realism, durability, and professional detailing, making it an excellent choice for display, marketing, and collection purposes.

DX140W DX140W-3 DX140W-5 DX170W-5 DX190W-3 1.430-00026 1430-00026 1430-00026 GEAR SHIFT SYSTEM

The 1.430-00026 Gear Shift System is a vital transmission component designed for DOOSAN wheeled excavators, including models DX140W, DX140W-3, DX140W-5, DX170W-5, and DX190W-3. This gear shifting system ensures smooth and reliable transmission performance under various operating conditions, enabling your equipment to adapt seamlessly to job site demands.

Manufactured to meet or exceed OEM standards, this replacement unit by SPARKLING MACHINERY delivers exceptional durability, accurate shifting response, and easy installation—perfect for keeping your DOOSAN machine operating at peak performance.

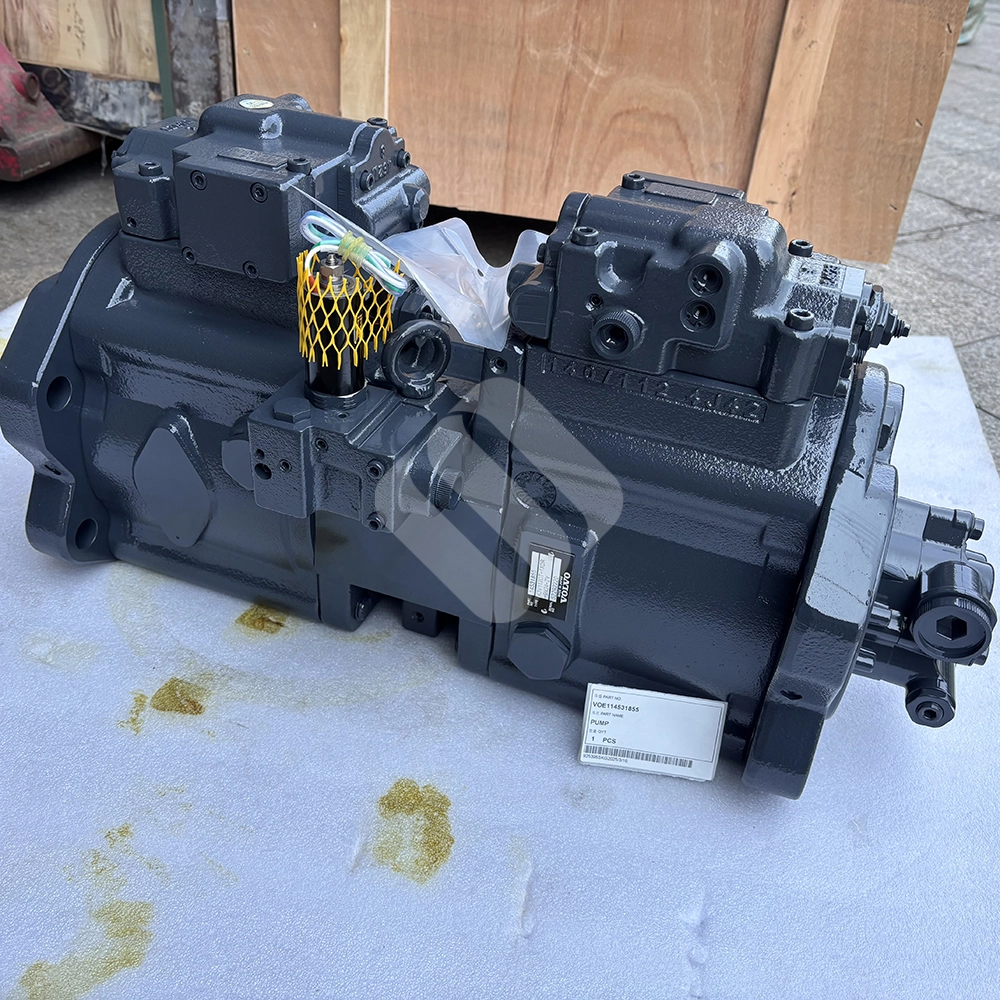

VOLVO MADE IN CHINA SPARKLING MACHINERY NEW EC210B EC210C VOE14531855 PUMP

SPARKLING MACHINERY NEW EC210B EC210C VOE14531855 Pump, a premium China-made hydraulic core component, is specifically engineered for EC210B and EC210C excavators, serving as the critical power transmission unit of hydraulic systems. It converts mechanical energy into stable hydraulic pressure to drive essential operations such as arm movement, bucket action, and lifting, ensuring seamless performance in construction, mining, and earthmoving tasks.

Crafted from high-strength alloy materials with precision-machined internal components, this pump withstands high pressure and continuous heavy loads while maintaining consistent performance. Equipped with advanced hydraulic regulation technology and multi-layer sealing systems, it minimizes leakage and resists dust, water, and debris intrusion, adapting to harsh working environments. Backed by strict quality testing and professional support, it guarantees reliable operation, reducing downtime and maximizing equipment productivity.

Sparkling Machinery Co.,Ltd

foreverlucia1