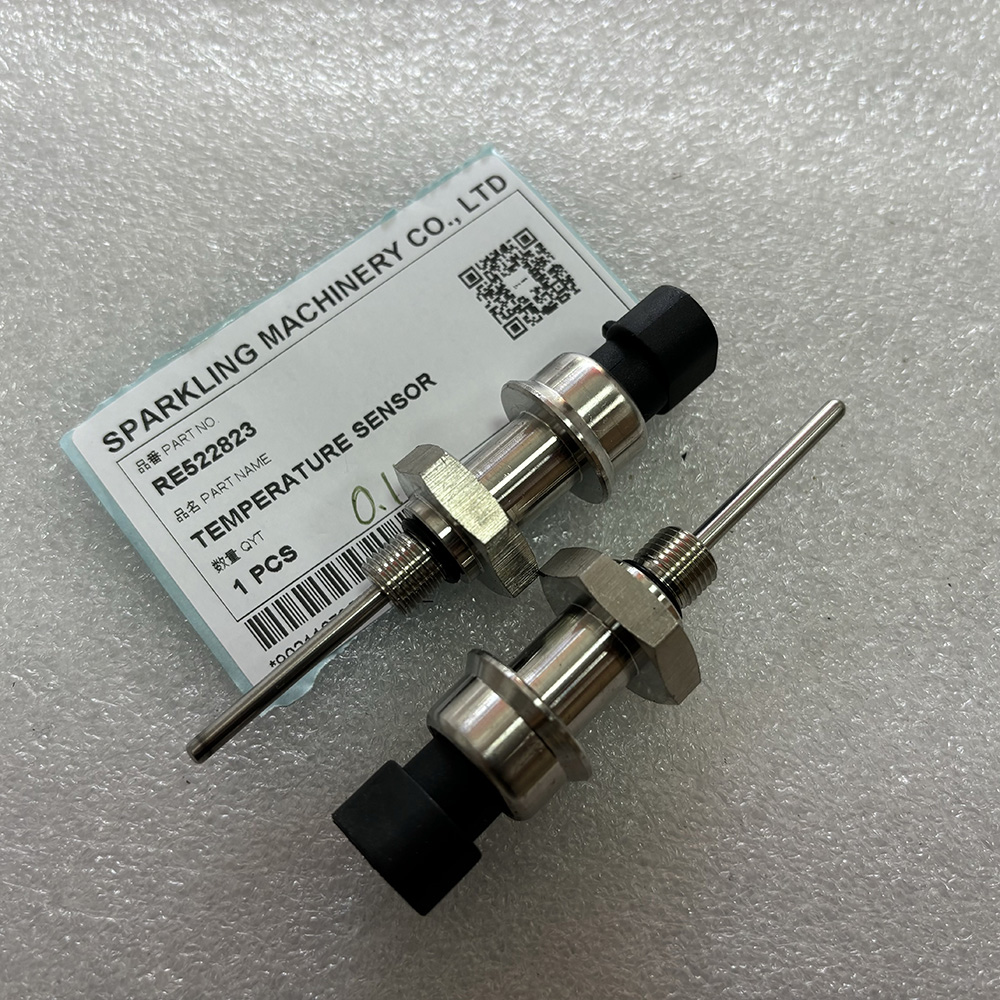

SPARKLING 670G Temp Sensor – Reliable Excavator Temperature Monitoring

The John Deere Temperature Sensor (RE522823) is a vital engine and hydraulic monitoring component for mid-to-large John Deere equipment—optimizing operational safety across models like the 1210E, 670G, 290GLC, 755D, 624K, 350DLC, and 953M. Engineered for precise temperature measurement, this two-terminal sensor ensures accurate data feedback to prevent overheating and protect critical engine components. Built to meet or exceed OEM standards, it delivers reliable performance in rugged environments.

SPARKLING 670G Temp Sensor – Precision You Can Trust

SPARKLING MACHINERY, established in 2013, proudly presents the 670G temp sensor, a vital component engineered for optimal excavator performance. Designed with stability, precision, and perseverance in mind, this high-quality temperature sensor ensures accurate monitoring of engine and hydraulic fluid temperatures, promoting reliable operation under the most demanding conditions.

Compatible with leading brands including Caterpillar, Komatsu, Hitachi, and Volvo, the SPARKLING 670G temp sensor integrates seamlessly into your machinery, providing real-time temperature data that helps prevent overheating and component failure. Manufactured through rigorous quality control processes, this sensor guarantees durability and operational consistency, extending the life of your excavator and minimizing maintenance costs.

At SPARKLING MACHINERY, we not only offer High Quality parts but also provide customized solutions and dedicated technical support tailored to your needs. Our extensive industry experience and commitment to innovation ensure you receive meticulous consultation and continuous after-sales service. We strive to deliver competitive prices without compromising on quality, helping customers reduce operational expenses while boosting overall machine efficiency.

Choose the SPARKLING 670G temp sensor for unparalleled accuracy, robust construction, and dependable performance. Backed by a global sales network, SPARKLING MACHINERY is your trusted partner in excavator excellence, advancing our vision of becoming the world's top excavator parts manufacturer.

Picture Show

Q&A

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

If you have any questions or concern, please contact us.

John Deere Temperature Sensor RE522823 – Fits 1210E • 670G • 290GLC • 755D • 624K • 350DLC • 953M

The John Deere Temperature Sensor (RE522823) is a vital engine and hydraulic monitoring component for mid-to-large John Deere equipment—optimizing operational safety across models like the 1210E, 670G, 290GLC, 755D, 624K, 350DLC, and 953M. Engineered for precise temperature measurement, this two-terminal sensor ensures accurate data feedback to prevent overheating and protect critical engine components. Built to meet or exceed OEM standards, it delivers reliable performance in rugged environments.

Construction Machinery Spare Parts 702-21-56600 Pilot Valve for Komatsu PC160LC-7 PC160LC-7E0

Doosan EXCAVATOR PARTS MADE IN CHINA NEW B55W-2 DX53W DX55W DX60R 1.519-00002 COIL;SOLENOID SPARKLING MACHINERY

SPARKLING MACHINERY NEW B55W-2 DX53W DX55W DX60R 1.519-00002 Coil; Solenoid is a dedicated electrical control component for Doosan B55W-2, DX53W, DX55W, and DX60R wheeled excavators (versatile for municipal engineering, landscaping, and small-scale construction). As a key part of the excavator’s hydraulic or fuel system, it converts electrical signals into electromagnetic force to control valve actuation, ensuring precise operation of functions like bucket tilting, arm movement, and engine fuel supply during delicate tasks.

Meeting Doosan OEM standards (part no. 1.519-00002), it endures -30°C to 85°C temperatures, resists vibration and electrical interference, and maintains stable switching performance. Strict testing guarantees seamless compatibility and long-term reliable operation for the four Doosan models.

Caterpillar EXCAVATOR PARTS MADE IN CHINA NEW 416E 416F 420F 422E 422F 308-2890 KIT-REGULATO SPARKLING MACHINERY

SPARKLING MACHINERY NEW 416E 416F 420F 422E 422F 308-2890 Kit-Regulato is a dedicated hydraulic regulation component kit for Caterpillar 416E, 416F, 420F, 422E, and 422F backhoe loaders/excavators (widely used in construction, municipal engineering, and agricultural operations). As a core set for the equipment’s hydraulic system, it fine-tunes pressure, flow, and valve response to ensure consistent performance of key functions—like buc Your Caterpillar’s trusted hydraulic regulation solution starts here.

Now, we’re proud to present the CATERPILLAR EXCAVATOR PARTS MADE IN CHINA NEW 416E 416F 420F 422E 422F 308-2890 KIT-REGULATO by SPARKLING MACHINERY. Next, we’ll cover its core strengths: seamless compatibility with five Caterpillar models, precise hydraulic tuning, rigorous quality, and more—helping you see how it boosts your equipment’s operational consistency and cuts maintenance troubles.ket digging, boom lifting, and steering—even under variable workloads.

Meeting Caterpillar OEM standards (part no. 308-2890), it endures 28 MPa hydraulic pressure, -30°C to 95°C temperatures, resists oil corrosion and vibration, and maintains stable regulation. Strict testing guarantees seamless compatibility with the five models and long-term hydraulic system efficiency.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879