SPARKLING 7204752 Travel Device – Reliable Excavator Part

The Travel Device Assembly / Final Drive Assy is an essential component in your excavator’s undercarriage system, responsible for converting hydraulic energy into mechanical movement, enabling the machine to crawl with precision, stability, and power.

This product is designed for compatibility with a range of Hitachi compact and medium excavators, ensuring direct fit, smooth torque transfer, and long-term durability even in challenging jobsite conditions.

Each unit is manufactured using high-strength gears, reliable oil seals, and precision assembly to guarantee quiet operation, resistance to wear, and stable output power.

SPARKLING 7204752 Travel Device – Precision and Reliability You Can Trust

Founded in 2013, SPARKLING MACHINERY has established itself as a leader in high-quality excavator parts, dedicated to delivering products characterized by stability, precision, and durability. The SPARKLING 7204752 travel device exemplifies our commitment to excellence, designed to enhance the performance and reliability of your excavator under various operating conditions.

Compatible with top excavator brands such as Caterpillar, Komatsu, Hitachi, and Volvo, the 7204752 travel device boasts superior engineering and stringent quality control. Manufactured with High Quality materials and advanced technology, this travel device ensures smooth, efficient movement and long-lasting durability in even the most demanding environments.

At SPARKLING MACHINERY, our product range extends beyond travel devices to include hydraulic components, undercarriage systems, engine components, electrical parts, cabs, mini excavators, and accessories. We offer customized solutions tailored to your specific needs, backed by expert technical support and meticulous consultation services to optimize your operations while minimizing downtime and costs.

With a robust global sales network and an unwavering focus on altruism and innovation, SPARKLING MACHINERY provides competitive pricing without compromising product quality. Partnering with us means choosing a trusted supplier committed to your satisfaction and success.

Upgrade your excavator’s performance with the SPARKLING 7204752 travel device — where precision meets reliability.

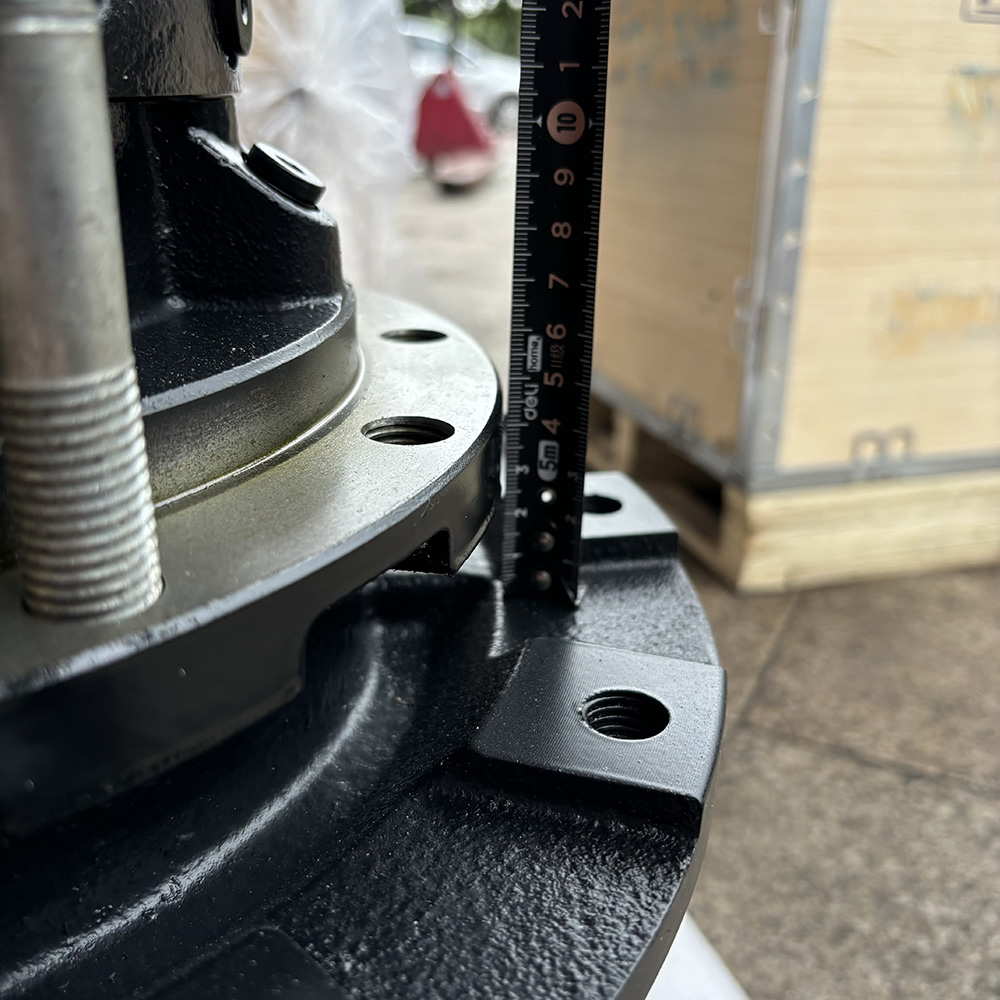

Product Images

Question you may concern

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

ZR240JC ZX70 ZX70-HHE ZX80LCK ZX80SB-HCME 9224123 9224241 9190694 7204752 TRAVEL DEVICE ASS'Y FINAL DRIVE ASSY

The Travel Device Assembly / Final Drive Assy is an essential component in your excavator’s undercarriage system, responsible for converting hydraulic energy into mechanical movement, enabling the machine to crawl with precision, stability, and power.

This product is designed for compatibility with a range of Hitachi compact and medium excavators, ensuring direct fit, smooth torque transfer, and long-term durability even in challenging jobsite conditions.

Each unit is manufactured using high-strength gears, reliable oil seals, and precision assembly to guarantee quiet operation, resistance to wear, and stable output power.

KOMATSU MADE IN CHINA SPARKLING MACHINERY NEW 334/C2147 RADIATOR

SPARKLING MACHINERY NEW 334/C2147 Radiator is a critical cooling system component tailored for compatible heavy-duty construction machinery, such as excavators and loaders. As the core of the machinery’s heat dissipation system, it efficiently transfers heat from engine coolant to the surrounding air—preventing engine overheating during high-intensity operations like prolonged digging, heavy-load lifting, and continuous idling in construction, mining, or infrastructure projects. This function is vital for maintaining the engine’s optimal operating temperature (typically 82–95°C), which directly influences fuel efficiency, power output, and the long-term service life of key engine components.

Engineered to match original equipment performance standards, it retains strong heat dissipation efficiency even under harsh working conditions, including high ambient temperatures, dust accumulation, and constant machinery vibration. It resists coolant leakage and internal blockages, avoiding cooling system failures that could lead to costly engine damage or unplanned downtime. Backed by strict performance verification, it guarantees reliable heat exchange to support uninterrupted operation of compatible heavy-duty machinery.

418-12-41111 Coupling for Komatsu Wheel Loaders | Fits WA200-5, WA200-5L, WA250-5, WA250-5L

The 418-12-41111 coupling is a high-performance flange coupling (non-hub type) engineered as a direct OEM replacement for Komatsu wheel loaders WA200-5/WA200-5L/WA250-5/WA250-5L (also fits WA200-6/WA250-6/WA270-5).

· Function: This flexible coupling is installed between the engine flywheel and the hydraulic pump to transmit engine power smoothly and accommodate slight misalignments and vibrations.

· Design: The part number often cross-references with other Komatsu numbers like 418-12-31110 and 418-12-61110, which are part of the same assembly.

Compatible Equipment

The 418-12-41111 coupling is primarily compatible with several models of Komatsu Wheel Loaders:

· WA200 Series: WA200-5, WA200-5L, WA200-6, WA200L-5, WA200PT-5, WA200PTL-5, WA200PZ-6

· WA250 Series: WA250-5, WA250-5L, WA250-6, WA250L-5, WA250PT-5, WA250PTL-5, WA250PZ-6

· WA270 Series: WA270-5

JCB HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 56589-15021 PANEL SPARKLING MACHINERY

SPARKLING MACHINERY NEW 56589-15021 Panel is a core structural and protective component for JCB excavators (heavy-duty construction/mining use). It serves as an external or internal cover to shield cabin controls, electrical systems, or mechanical parts from dust, impact, and weather, while maintaining equipment aesthetics.

Meeting JCB OEM standards (56589-15021), it resists -30°C to 100°C temps, corrosion, and wear, ensuring seamless compatibility and long-term reliable protection for JCB excavator systems.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879