SPARKLING 9224241 Hitachi Parts – High-Quality Excavator Components

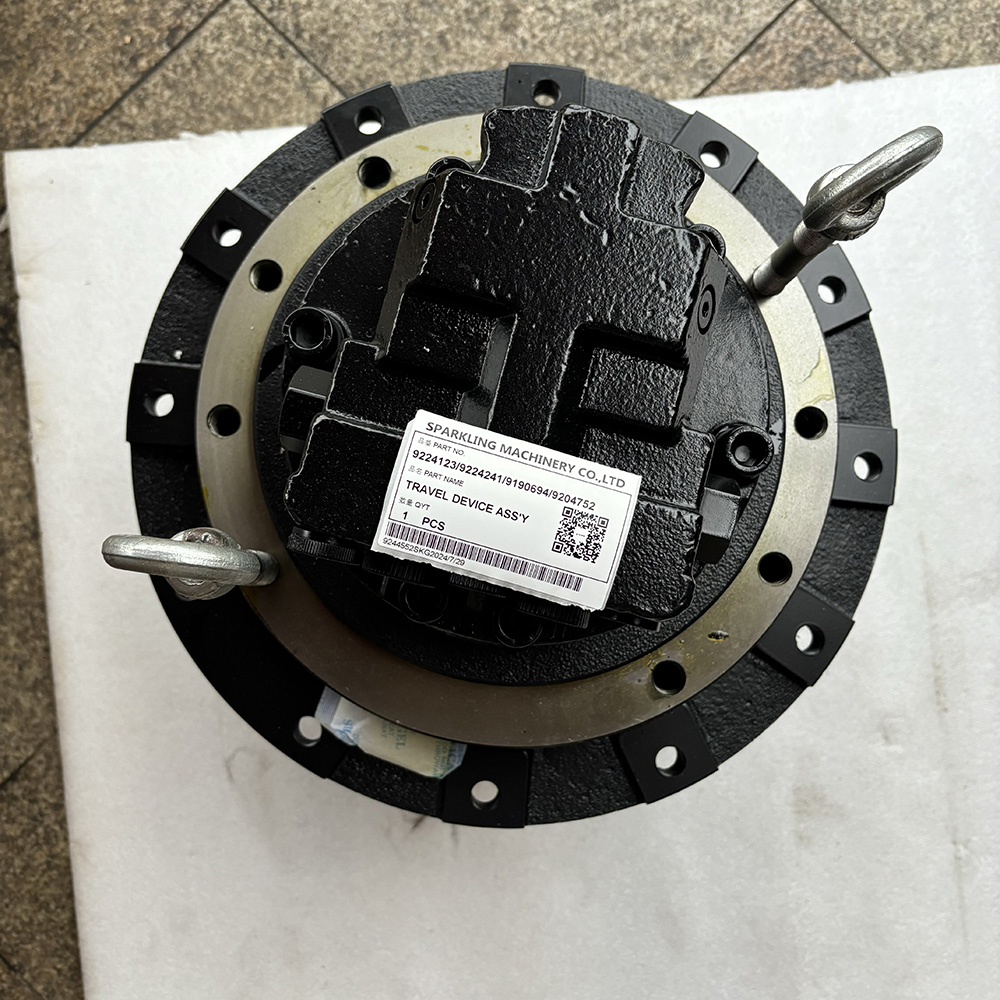

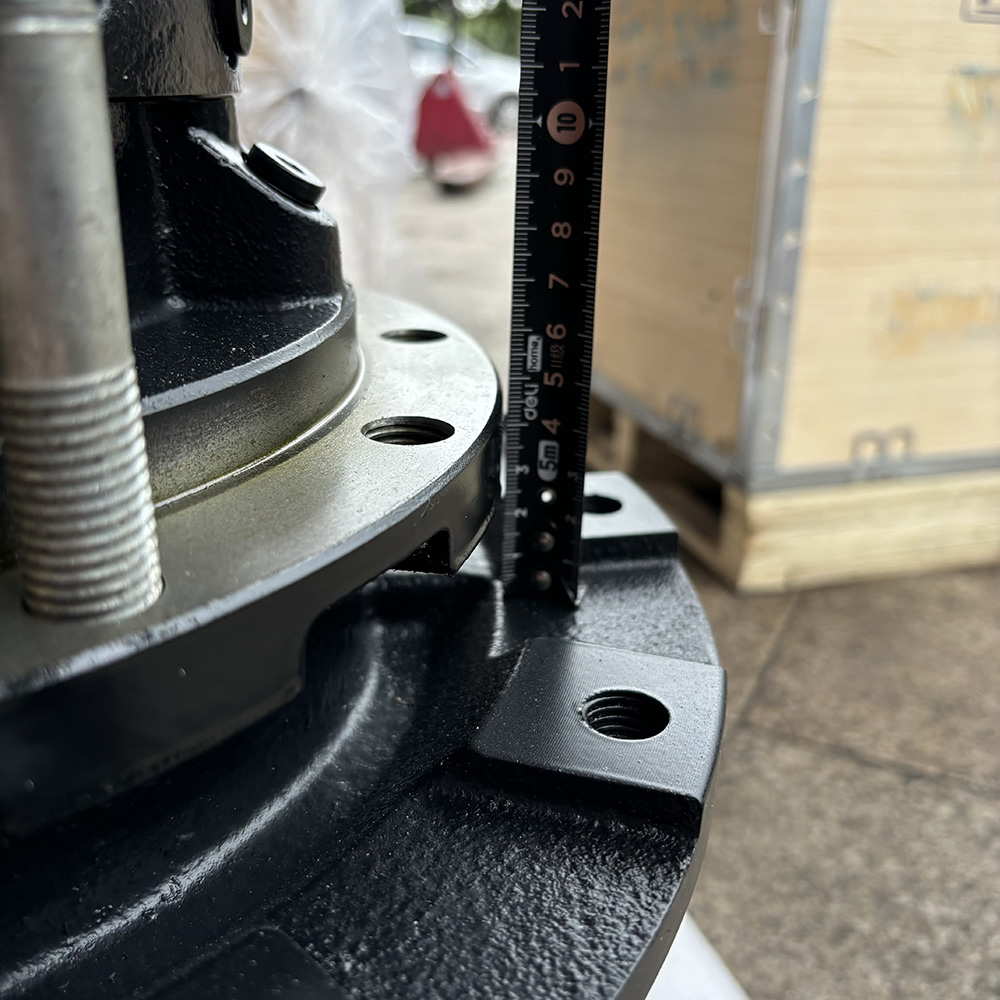

The Travel Device Assembly / Final Drive Assy is an essential component in your excavator’s undercarriage system, responsible for converting hydraulic energy into mechanical movement, enabling the machine to crawl with precision, stability, and power.

This product is designed for compatibility with a range of Hitachi compact and medium excavators, ensuring direct fit, smooth torque transfer, and long-term durability even in challenging jobsite conditions.

Each unit is manufactured using high-strength gears, reliable oil seals, and precision assembly to guarantee quiet operation, resistance to wear, and stable output power.

SPARKLING 9224241 Hitachi Parts – Reliable Quality for Optimal Excavator Performance

SPARKLING MACHINERY, established in 2013, is a leading provider of high-quality excavator parts dedicated to stability, precision, and perseverance. Our 9224241 Hitachi parts are engineered to guarantee exceptional performance and durability, meeting the rigorous demands of construction and heavy machinery applications.

As specialists in excavator components, SPARKLING offers an extensive product range, including hydraulic components, undercarriage systems, engine parts, electrical units, cabs, mini excavators, and accessories. Our products are compatible with renowned brands such as Caterpillar, Komatsu, Hitachi, and Volvo, ensuring seamless integration and reliability.

The 9224241 Hitachi parts by SPARKLING are manufactured under stringent quality control standards to ensure they withstand diverse working environments. We customize solutions tailored to your unique needs, supported by professional technical consultation and continuous customer service.

Committed to innovation and altruism, SPARKLING MACHINERY provides competitive pricing without compromising on quality, helping customers reduce operational costs while maintaining peak equipment efficiency. Our global sales network reinforces our position as a trusted partner in the excavator parts industry.

Choose SPARKLING for your 9224241 Hitachi parts and experience reliable performance, precise engineering, and dedicated support — the foundation of every successful project.

Detailed display

Question you may concern

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

If you have another questions, please feel free to contact us.

ZR240JC ZX70 ZX70-HHE ZX80LCK ZX80SB-HCME 9224123 9224241 9190694 7204752 TRAVEL DEVICE ASS'Y FINAL DRIVE ASSY

The Travel Device Assembly / Final Drive Assy is an essential component in your excavator’s undercarriage system, responsible for converting hydraulic energy into mechanical movement, enabling the machine to crawl with precision, stability, and power.

This product is designed for compatibility with a range of Hitachi compact and medium excavators, ensuring direct fit, smooth torque transfer, and long-term durability even in challenging jobsite conditions.

Each unit is manufactured using high-strength gears, reliable oil seals, and precision assembly to guarantee quiet operation, resistance to wear, and stable output power.

HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW A0070056099 WATER SEPARATOR FILTER BOWL SPARKLING MACHINERY

SPARKLING MACHINERY NEW A0070056099 Water Separator Filter Bowl is a core fuel system component for excavators (heavy-duty construction/mining use). It separates water and contaminants from fuel to protect engines from corrosion and wear.

Meeting high OEM standards (A0070056099), it resists -30°C to 100°C temps, corrosion, and pressure, ensuring seamless compatibility and long-term reliable fuel purification performance.

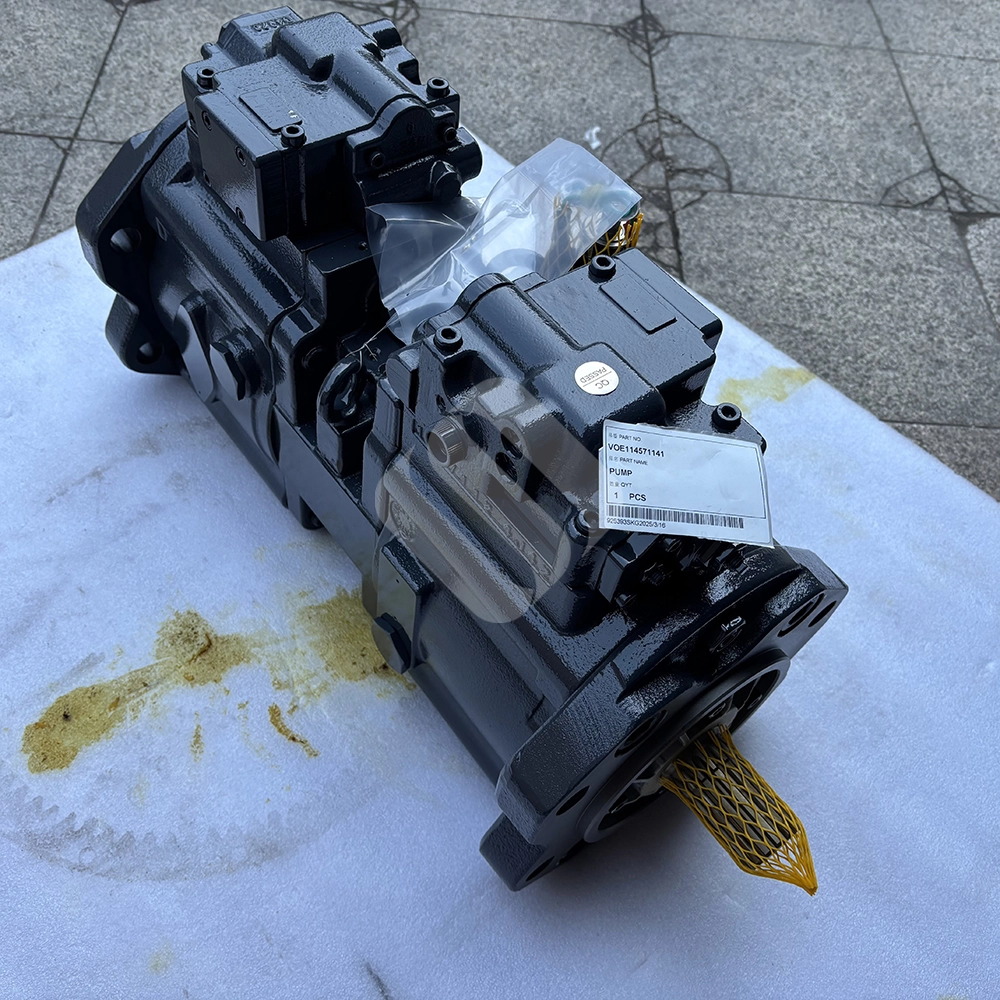

VOLVO MADE IN CHINA SPARKLING MACHINERY NEW EC200B EC210B VOE14571141 PUMP

SPARKLING MACHINERY NEW EC200B EC210B VOE14571141 Pump - a high-quality China-made hydraulic core component, is specifically engineered for Volvo EC200B and EC210B excavators, serving as the critical power source for hydraulic systems. It converts mechanical energy into stable hydraulic pressure to drive essential operations such as arm movement, bucket action, and lifting, ensuring seamless performance in construction, mining, and earthmoving tasks.

Crafted from high-strength alloy materials with precision-machined internal components, this pump withstands high pressure and continuous heavy loads. Equipped with advanced hydraulic regulation technology and multi-layer sealing systems, it minimizes leakage and resists dust, water, and debris, adapting to harsh working environments. Backed by strict quality testing and professional support, it guarantees reliable operation, reducing downtime and maximizing equipment productivity.

2674370 Turbocharger for Perkins T6.3544 & 6-354.4 Engines – Construction Machinery Spare Parts

The 2674370 turbocharger is an OEM-replacement forced-induction unit for Perkins T6.3544 and 6-354.4 engines. It boosts intake pressure to enhance combustion, delivering up to 30% more power and 15% better fuel efficiency compared to naturally aspirated setups, while ensuring durability in heavy-duty cycles.

Key Features

· OEM-Matched Precision: Exact fit for T6.3544/6-354.4; turbine/compressor wheels balanced to OEM specs for vibration-free operation and plug-and-play installation.

· High-Temp Resistance: Nickel-based alloy turbine housing withstands 850°C exhaust temps; stainless steel rotor shafts resist corrosion and fatigue.

· Enhanced Efficiency: T04B71 compressor wheel delivers 18 psi max boost; optimized airflow reduces turbo lag by 25% for faster throttle response.

Compatible Equipment

· Engines: Perkins T6.3544, 6-354.4 (fits industrial/construction machinery with these engines)

· Interchangeable Part Numbers: 2674370, 465154-0011, 2674368, 465154-0009

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879