SPARKLING Aftermarket JCB Hydraulic Parts – Quality & Reliability

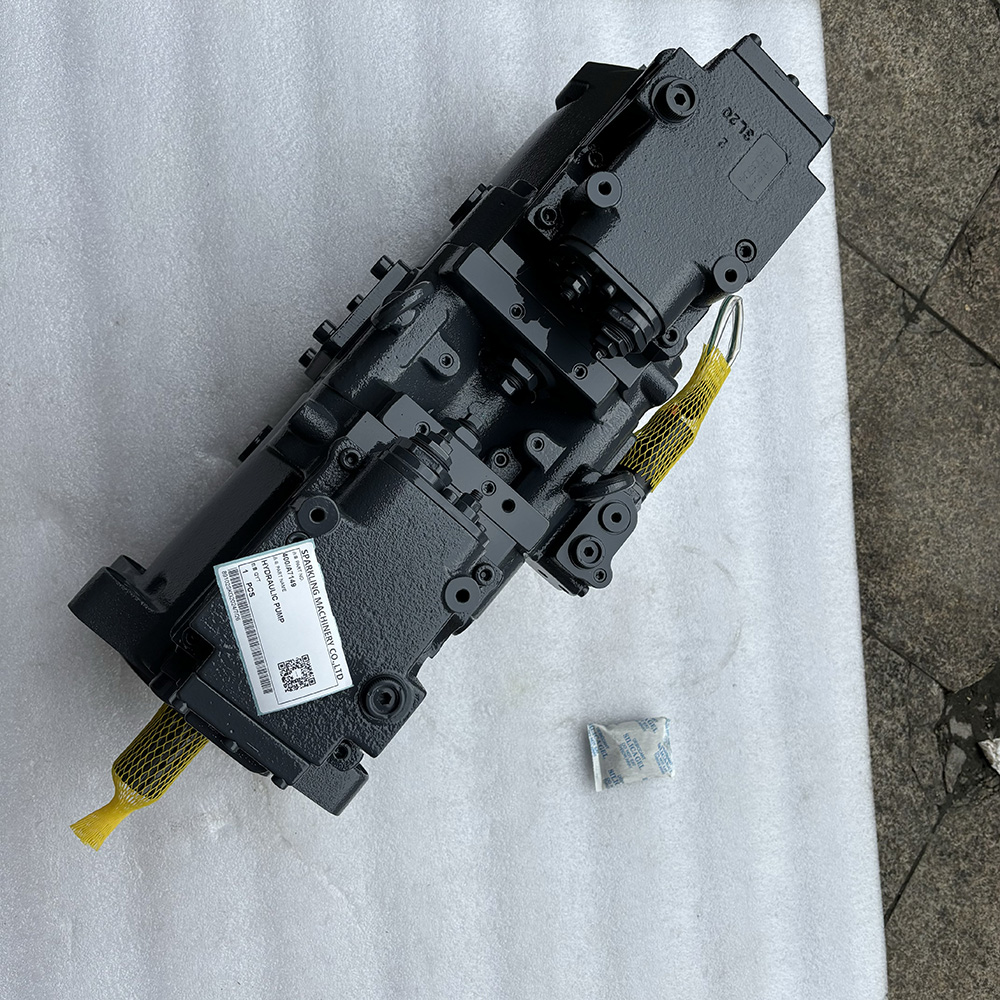

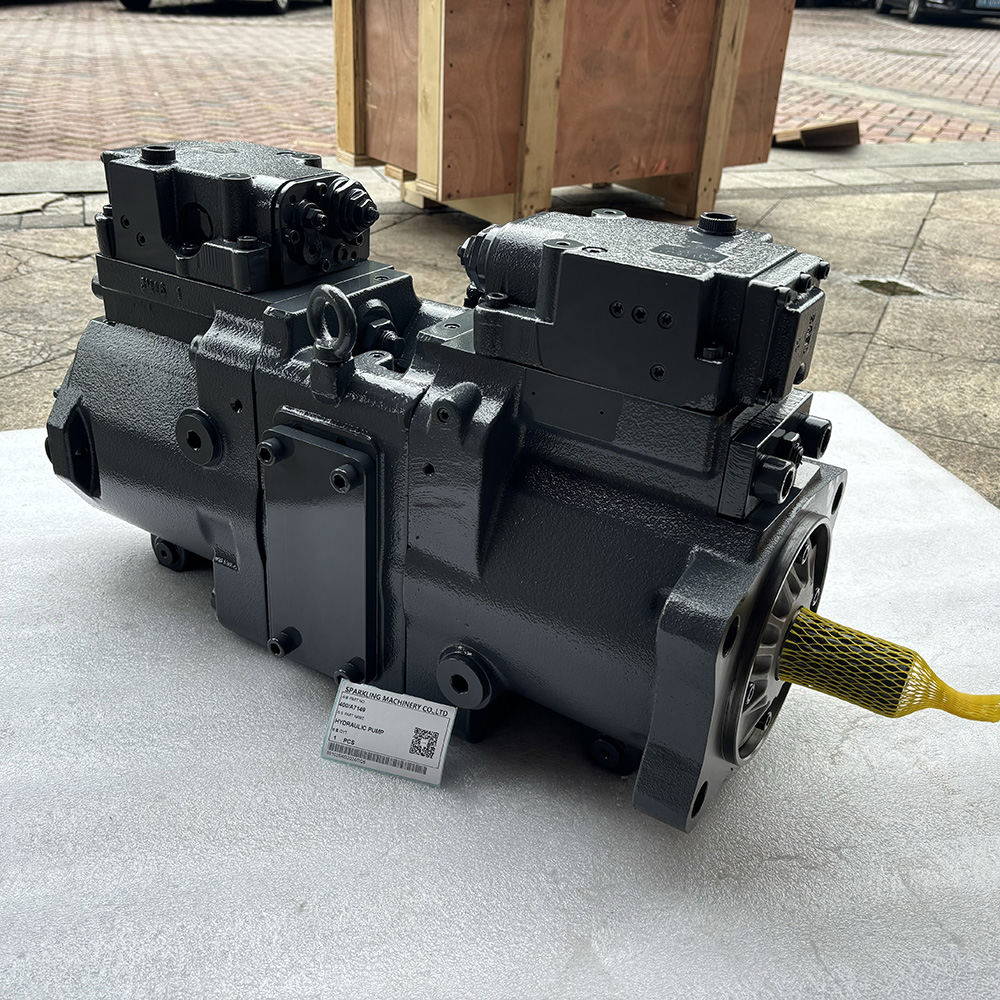

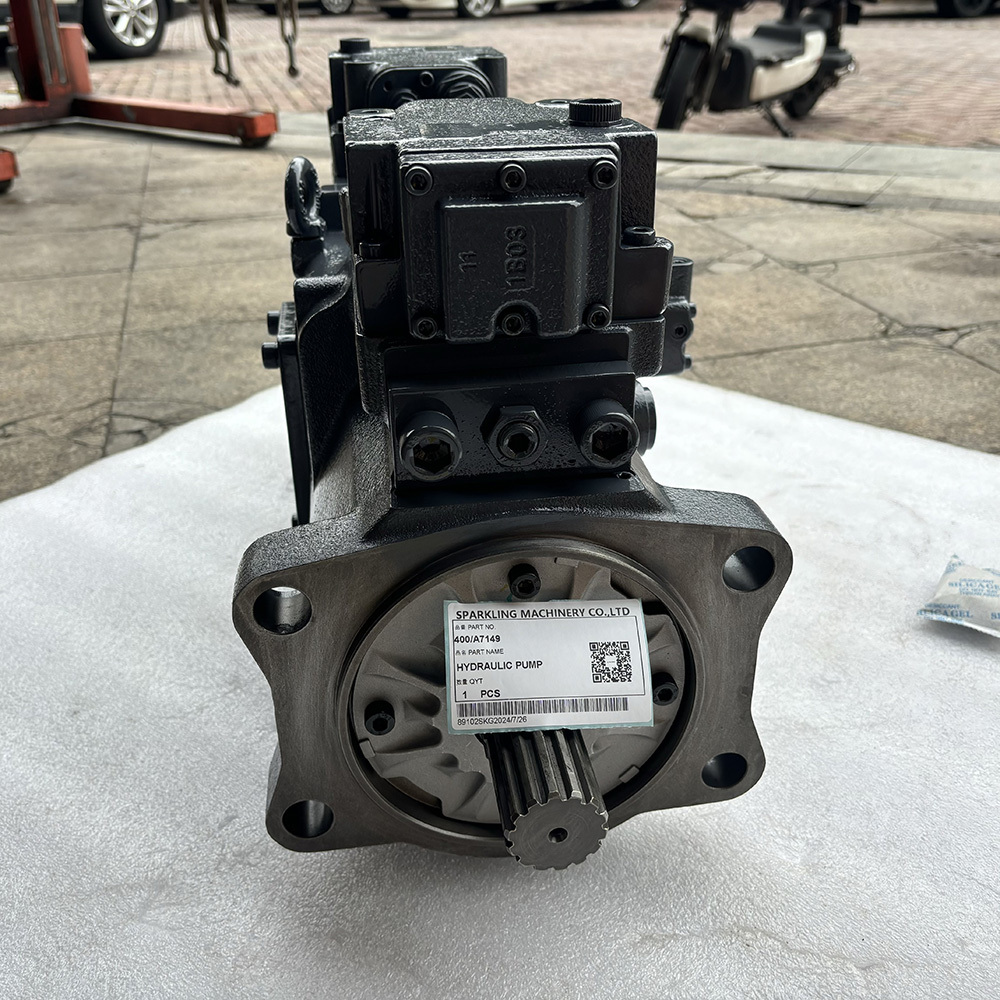

The 400/A7149 Hydraulic Main Pump Assembly is a high-efficiency, China-manufactured replacement pump designed to match or exceed original JCB standards. Engineered with precision and built using upgraded internal components, this pump ensures strong flow delivery, stable pressure, and reliable performance in heavy-duty construction and excavation applications.

It is a direct-fit solution for JCB models using this pump reference, providing excellent value without compromising on quality. Each unit is 100% factory-tested to guarantee durability and smooth operation under tough working conditions.

SPARKLING Aftermarket JCB Hydraulic Parts: Reliable Performance You Can Trust

Since 2013, SPARKLING MACHINERY has been dedicated to delivering high-quality aftermarket JCB hydraulic parts designed to enhance the performance and longevity of your machinery. Our products are crafted with precision and built for stability, ensuring your JCB excavators operate smoothly in the toughest working conditions.

Our extensive range of hydraulic components is engineered to meet and exceed OEM standards, providing exceptional reliability and compatibility with JCB equipment. Whether you need pumps, valves, cylinders, or hoses, SPARKLING’s aftermarket JCB hydraulic parts are tested through stringent quality control processes to guarantee durability and optimal function.

At SPARKLING MACHINERY, we understand that your equipment’s uptime directly impacts your productivity and profitability. That’s why we offer not only quality parts but also customized solutions and professional technical support to help you choose the right hydraulic components tailored to your specific needs. Our worldwide sales network ensures fast delivery and continuous service, so you never have to worry about downtime.

Choosing SPARKLING means choosing a partner who values innovation, cost-effectiveness, and customer satisfaction. Our commitment to providing competitive pricing without compromising on quality helps you reduce operational costs while maintaining top performance. Trust SPARKLING MACHINERY for aftermarket JCB hydraulic parts that support your success every step of the way.

Detailed display

Question you may concern

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

JCB 400/A7149 HYDRAULIC MAIN PUMP ASSY CHINA MADE BETTER QUALITY

The 400/A7149 Hydraulic Main Pump Assembly is a high-efficiency, China-manufactured replacement pump designed to match or exceed original JCB standards. Engineered with precision and built using upgraded internal components, this pump ensures strong flow delivery, stable pressure, and reliable performance in heavy-duty construction and excavation applications.

It is a direct-fit solution for JCB models using this pump reference, providing excellent value without compromising on quality. Each unit is 100% factory-tested to guarantee durability and smooth operation under tough working conditions.

HYUNDAI HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW HW210 R170W9 R200W7 R200W7A ZGAQ-02343 CROSS-JOINT SPARKLING MACHINERY

SPARKLING MACHINERY NEW ZGAQ-02343 Cross-Joint is a core power transmission component for Hyundai HW210/R170W9/R200W7/R200W7A excavators (construction/mining use). It enables flexible power transfer between rotating shafts at varying angles, ensuring smooth torque transmission.

Meeting Hyundai OEM standards (Part No.: ZGAQ-02343), it features high wear resistance and impact resistance, guaranteeing seamless compatibility and reliable long-term transmission performance.

708-3T-04210 BLOCK ASS'Y for Komatsu Construction Equipment LPD45 PC70 PC78MR PC78US PC78UU

The 708-3T-04210 BLOCK ASS'Y is a high-precision hydraulic pump cylinder block assembly designed for Komatsu LPD45, PC70, PC78MR, PC78US, and PC78UU excavators. As a core component of the hydraulic pump, it ensures efficient fluid displacement, stable pressure output, and reliable power transmission for the machine’s hydraulic system, even under heavy-load and continuous operation in construction and mining sites.

Common Applications: Primarily used in LPD45 type hydraulic piston pumps.

Dimensions: Approximately L=83 mm and D=123 mm.

Applicable Komatsu Models:

PC70 Series: PC70-8.

PC78 Series: PC78US-6, PC78UU-6, PC78MR-6.

PC88 Series: PC88MR-8, PC88MR-10.

HYUNDAI WHEEL EXCAVATOR R140W-9 FRONT AXLE STEERING GEAR ZGAQ-04067 CYLINDER-STEERING

The Hyundai ZGAQ-04067 Steering Cylinder is a precision-engineered hydraulic component for the front axle steering gear of the R140W-9 wheel excavator, delivering responsive steering performance and reliable durability in demanding jobsite conditions.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879