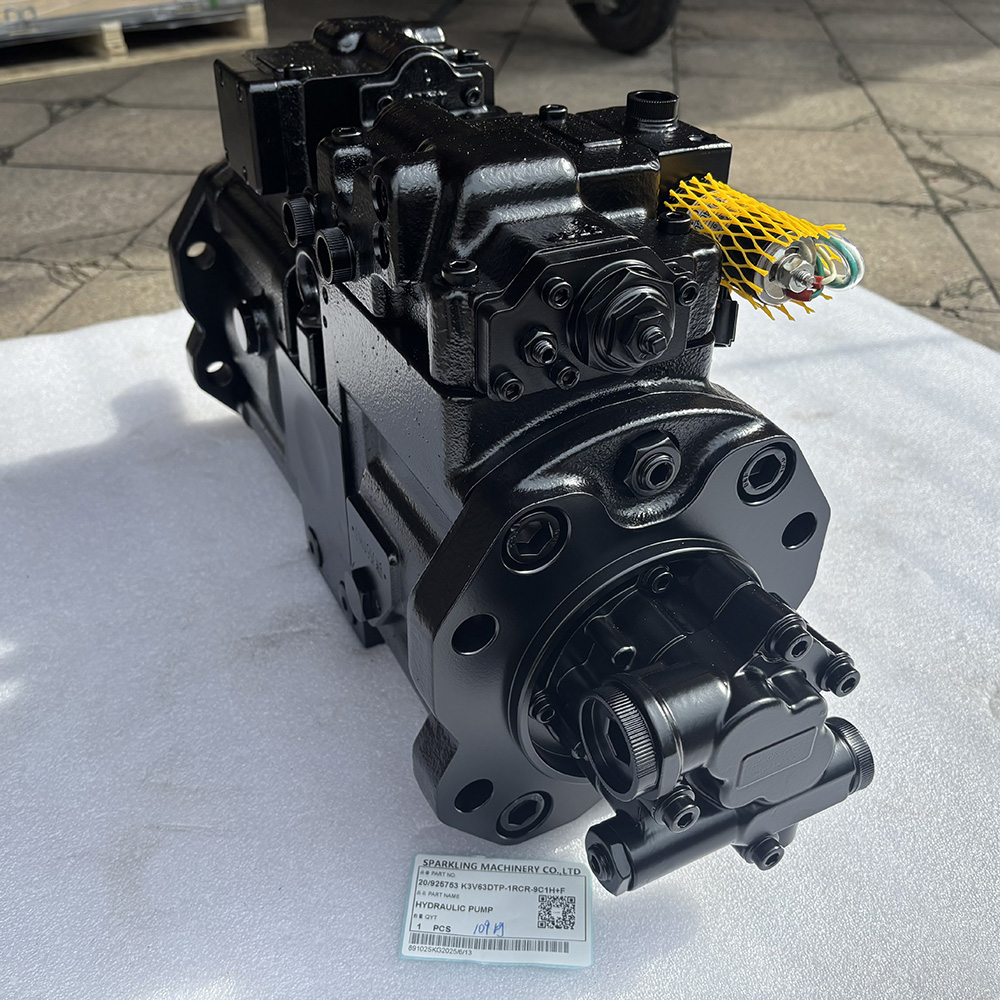

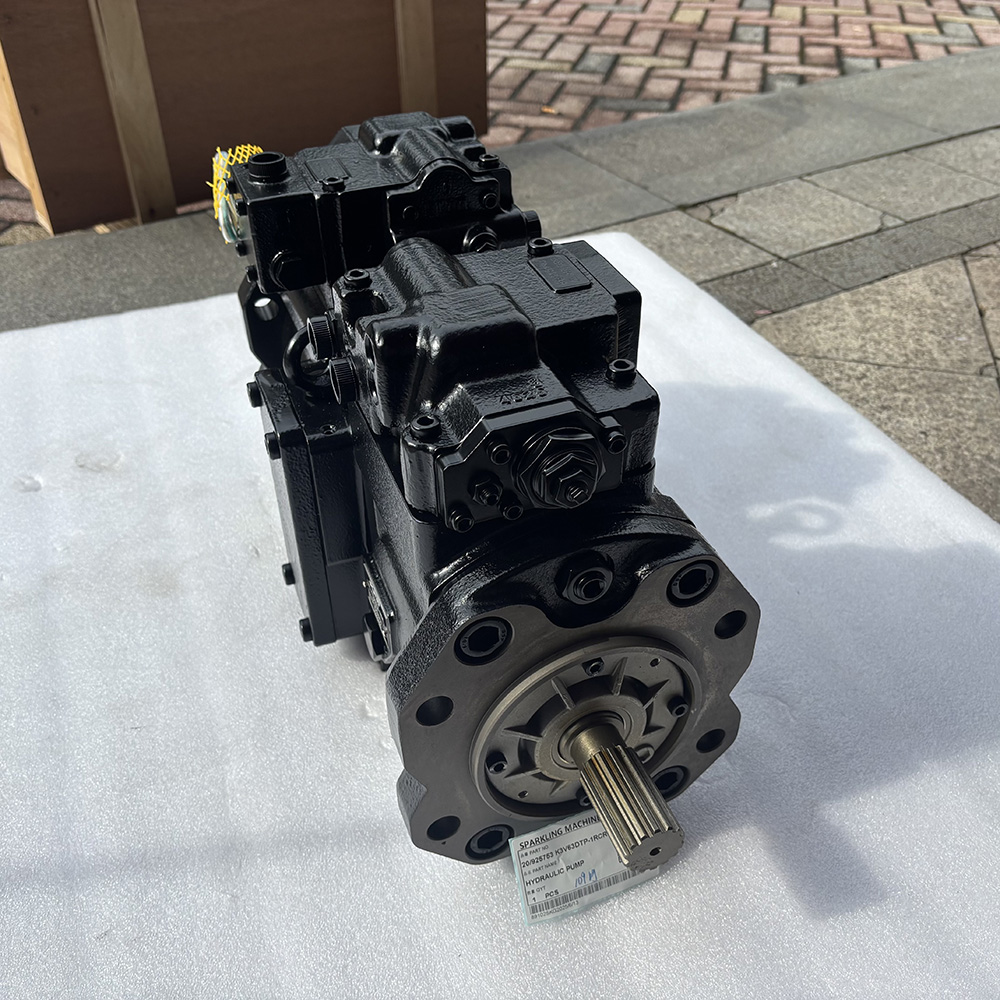

SPARKLING Aftermarket Kawasaki Excavator Pump – Reliable & Durable

The Kawasaki K3V63DTP Hydraulic Main Pump (Cat. no. 20/925753) is a high-performance action pump engineered for JCB JS160W and similar excavator models. This piston-type pump delivers robust hydraulic flow (~63 cc/rev) at pressures up to 350 bar, ensuring smooth boom, arm, and travel functions even under heavy load. Built to match Kawasaki OEM specs, it offers seamless drop-in installation and is backed by quality assurance—available as brand-new, remanufactured, or aftermarket options.

Introducing the SPARKLING aftermarket Kawasaki pump – a High Quality replacement part designed specifically for excavators. Since 2013, SPARKLING MACHINERY has been dedicated to producing reliable and high-quality excavator components. Our Kawasaki pump is crafted with precision and durability in mind, ensuring your machine operates smoothly in demanding work environments.

This aftermarket pump delivers excellent hydraulic performance, maintaining the power and stability your excavator requires to handle heavy-duty tasks. Built to strict quality standards, it fits seamlessly with Kawasaki hydraulic systems, making installation straightforward and minimizing downtime.

At SPARKLING, we understand the importance of durability and efficiency in excavator parts. Our Kawasaki pump offers a cost-effective alternative to original equipment manufacturer (OEM) parts without compromising on quality. It is carefully tested to withstand various working conditions, ensuring longevity and reducing your operational costs.

By choosing SPARKLING, you gain more than just a replacement part; you get a trusted partner committed to supporting your equipment’s performance. We provide customized solutions, expert technical support, and continuous after-sales service to meet your needs.

Whether you’re operating Caterpillar, Komatsu, Hitachi, Volvo, or other major brands, our Kawasaki pump is designed to enhance your excavator’s functionality and reliability. Trust SPARKLING to power your machine efficiently and help you get the job done right.

Detailed display

Question you may concern

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

If you have any questions about our goods or services, please feel free to contact us.

JS160W EXCAVATOR 20/925753 KAWASAKI K3V63DTP HYDRAULIC PUMP

The Kawasaki K3V63DTP Hydraulic Main Pump (Cat. no. 20/925753) is a high-performance action pump engineered for JCB JS160W and similar excavator models. This piston-type pump delivers robust hydraulic flow (~63 cc/rev) at pressures up to 350 bar, ensuring smooth boom, arm, and travel functions even under heavy load. Built to match Kawasaki OEM specs, it offers seamless drop-in installation and is backed by quality assurance—available as brand-new, remanufactured, or aftermarket options.

Common Rail Fuel Injector 295050-1401 for Isuzu 4HK1 6HK1 Engine and for Hitachi Excavator 8-98238463-1 8982384631

The Common Rail Fuel Injector (Part No. 295050-1401 / 8982384631 / 8-98238463-1) is a high-precision fuel injection component designed for Isuzu 4HK1 and 6HK1 diesel engines.

Enhance your engine's performance with this high-precision Common Rail Fuel Injector (Part No. 8-98238463-1 / 295050-1401). Engineered specifically for Isuzu 4HK1 and 6HK1 diesel engines, this injector ensures optimal fuel atomization, improved fuel efficiency, and reduced emissions. It is a critical component for maintaining the power and reliability of Isuzu trucks and Hitachi excavators.Engineered to deliver accurate fuel atomization and stable injection pressure, this injector ensures efficient combustion, improved engine power, and reduced fuel consumption. Manufactured using advanced machining and strict quality control, it meets OEM performance and fitment standards, making it a reliable replacement for original Isuzu fuel injectors.

This aftermarket common rail injector is widely used in Isuzu-powered excavators, trucks, and industrial equipment, and is suitable for engine maintenance, fuel system repair, and overhaul applications.

Brand: SPARKLING MACHINERY

Condition: New

Engine Models: Isuzu 4HK1 / 6HK1

Part Numbers: 295050-1401 8982384631 8-98238463-1

VOE17358525 Radiator Compatible with Volvo Construction Equipment EC220E

The VOE17358525 is an OEM-compatible engine cooling radiator, serving as the core heat dissipation component for Volvo EC220E excavators. It efficiently maintains engine operating temperature (82–95°C) with a cooling capacity of 45–50 kW, ensuring reliable performance of the D6E engine in construction, mining, and infrastructure projects.

Key Features

· OEM direct-fit design: Exact replication of mounting points, core dimensions, and hose interfaces for Volvo EC220E—plug-and-play installation without modifications.

· High cooling efficiency: Optimized tube-fin core structure (3-row aluminum tubes, 10 mm fin pitch) delivers 45–50 kW heat dissipation for consistent engine temperature control.

· Durable construction: High-quality aluminum core and tanks with anti-corrosion coating, reinforced brackets, and EPDM rubber gaskets resist vibration, pressure, and chemical degradation.

Compatible Machines: Volvo EC220E Excavator (D6E Engine)

Excavator Spare Parts 0.1KG 2566454 TEMPERATURE SENSOR for Caterpillar Equipment M313D M315D M316D

SPARKLING MACHINERY New Temperature Sensor (2566454) is a precision monitoring component dedicated to 312E, 320E and 324E excavators. As a core part of the engine and hydraulic system monitoring, it real-time detects coolant and hydraulic oil temperatures, and transmits accurate signals to the control panel. This prevents overheating during heavy-duty operations, ensures stable engine power, protects hydraulic components from thermal damage, and avoids unplanned downtime.

Function: Measures the temperature of the engine coolant or air inlet manifold to help maintain optimal engine operating conditions and ensure proper function of the engine control unit (ECU).

Material/Design: Features a durable brass or high-quality stainless steel body and a sealed, standard blade-style electrical connector designed for tough working conditions.

Specifications:

Thread Size: M18-1.5.

Overall Length: Approximately 1.81 inches (46 mm).

Cross Reference: This part can also cross-reference with the Perkins part number T407354.

Compatible Caterpillar Engines and Equipment:

Engines: C4.4, C6.6, C7, C7.1, C9, C9.3, C13, C15, C18.

Excavators: M313D, M315D, M316D, M318D, M322D, 312E, 312E L, 314E CR, 314E LCR, 316E L, 318E L, 320E, 320E L, 329E, 323F SA.

Generators: LC51XX, LC31XX.

Other Machinery: Wheel tractor-scrapers, wheel skidders, asphalt compactors, and mini hydraulic excavators (e.g., 304, 305).

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879