SPARKLING Axial Piston Pump – Durable Excavator Hydraulic Power

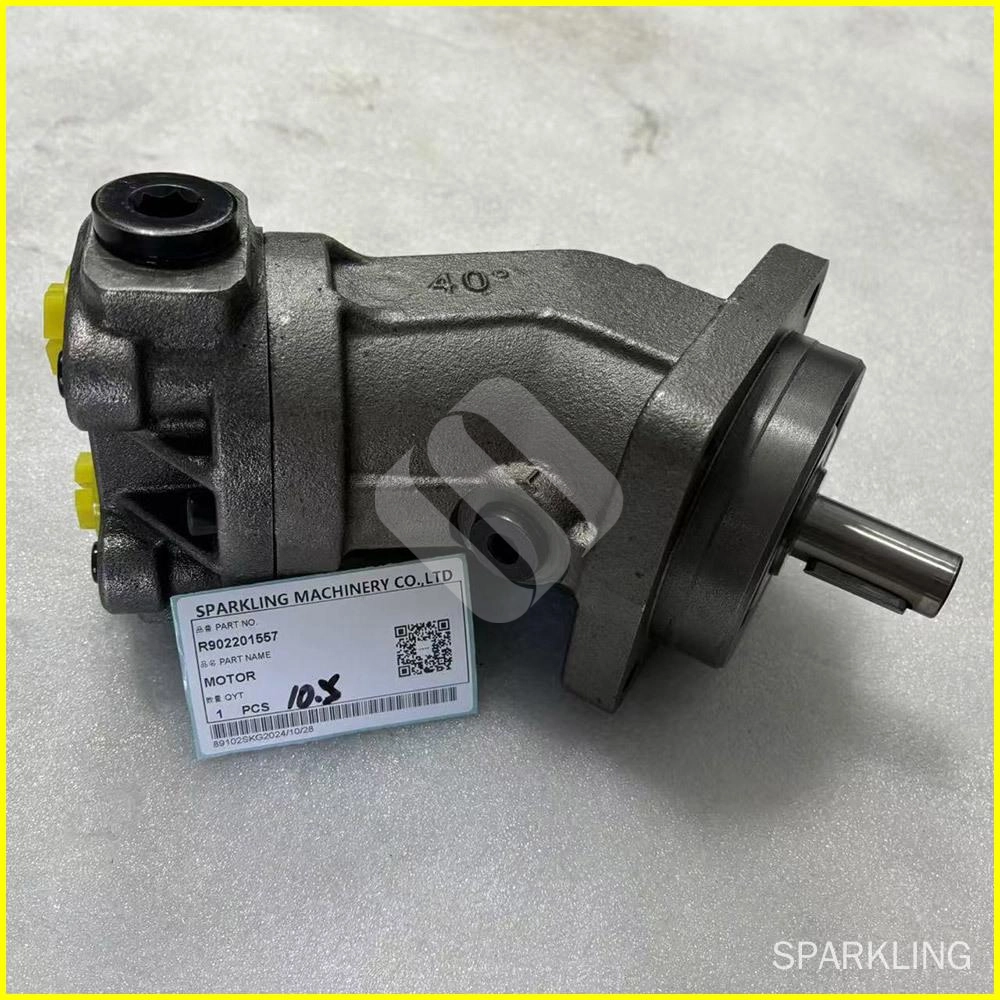

The Sparkling Machinery A2FM23 Hydraulic Pump (model R902201557) is a high-performance axial piston pump in fixed-displacement design, engineered for both open- and closed-circuit hydraulic systems like Rexroth’s A2FM23 range. Rated up to 400 bar nominal pressure (max. 450 bar), this pump delivers strong torque and stable flow under heavy-duty excavation scenarios. Featuring a compact bent-axis construction, it offers high power density and efficient operation in both mobile and stationary applications. It’s ideal for excavators, construction machinery, and industrial hydraulic systems requiring reliable, OEM-compatible performance.

SPARKLING Axial Piston Pump: Precision and Power for Your Excavator

SPARKLING MACHINERY, established in 2013, proudly presents its high-performance axial piston pump, engineered to deliver exceptional hydraulic power and efficiency for excavators. Designed for durability and precision, our axial piston pump is a vital component that ensures smooth, stable operation even under the toughest working conditions.

Crafted through stringent manufacturing processes and rigorous quality control, SPARKLING’s axial piston pumps boast superior resistance to wear and tear, providing long-lasting reliability. Compatible with leading brands like Caterpillar, Komatsu, Hitachi, and Volvo, our pumps are perfect for various heavy-duty applications, guaranteeing seamless integration and optimal functionality.

What sets the SPARKLING axial piston pump apart is our commitment to innovation, stability, and perseverance. We offer tailored solutions and comprehensive technical support to meet the specific needs of every client, helping you reduce maintenance costs and maximize productivity. Thanks to our precision engineering, the pump ensures high efficiency, lower energy consumption, and minimal downtime.

SPARKLING MACHINERY combines altruism with advanced technology, offering competitive prices without compromising quality. With a global sales network and ongoing customer service, we are your trusted partner in providing reliable hydraulic components that empower your excavator to perform at its best.

Choose SPARKLING axial piston pumps for stable, efficient, and cost-effective excavator operations, and experience the difference that quality and innovation can make.

Product Image

Frequently Asked Questions

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

SPARKLING MACHINERY EXCAVATOR SPARE PARTS A2FM23 R902201557 HYDRAULIC PUMP

The Sparkling Machinery A2FM23 Hydraulic Pump (model R902201557) is a high-performance axial piston pump in fixed-displacement design, engineered for both open- and closed-circuit hydraulic systems like Rexroth’s A2FM23 range. Rated up to 400 bar nominal pressure (max. 450 bar), this pump delivers strong torque and stable flow under heavy-duty excavation scenarios. Featuring a compact bent-axis construction, it offers high power density and efficient operation in both mobile and stationary applications. It’s ideal for excavators, construction machinery, and industrial hydraulic systems requiring reliable, OEM-compatible performance.

VOE11172358 Hydraulic Pump for Volvo Wheel Loader L60E L70E L90E L110E L60F L70F L90F L120F

VOE11172358 is the part number for a hydraulic pump (specifically a hydraulic main or auxiliary pump) designed for several Volvo wheel loaders.

Technical Specifications

Part Numbers: VOE11172358, 11172358, and cross-reference number R986110567.

Weight: Approximately 20kg.

Type: Tyrone-type pump or piston-style auxiliary pump.

Compatible Volvo Models

This pump is compatible with a wide range of Volvo wheel loader series, including:

L60 Series: L60E, L60F, L60GZ.

L70 Series: L70E, L70F.

L90 Series: L90E, L90F, L90GZ.

L110 Series: L110E, L110F.

L120 Series: L120E, L120F, L120GZ.

VOE11708990 Hydraulic Pump for Volvo Articulated Hauler A25D A30D A35D A40D DA25D DA30D

VOE11708990 (or 11708990) is a Hydraulic Axial Piston Pump specifically designed for Volvo Articulated Haulers and other heavy-duty machinery. It serves as a core component for converting mechanical energy into hydraulic pressure to power steering and dump mechanisms.

Equipment Compatibility

This pump is an OEM replacement part for a wide range of Volvo heavy equipment:

Articulated Haulers: A25D, A30D, A35D, A40D, DA25D, DA30D, and E-series (A25E, A30E).

Wheel Loaders: L90E, L110E, L120E, L150E, L180E.

Excavators: EC140, EC160, EC180.

Scraper Haulers: T450D.

Technical Specifications

Manufacturer: Bosch Rexroth is the primary OEM manufacturer (Part No: R986110559).

Type: Axial Piston Variable Pump (often referred to as an A10VO28 series in some configurations).

Nominal Pressure: Approximately 250 bar (3600 psi).

Weight: 22kg.

Durability: Rated for a cycle life of ≥ 50,000 operating hours under standard conditions.

VOE15079594 15079594 Hydraulic Pump for Volvo Articulated Haulers A25F A30F A35F A40F A25G A30G A35G A40G

VOE15079594 (also known by part number 15079594) is a high-pressure Hydraulic Axial Piston Pump primarily used as a main hydraulic pump for Volvo Articulated Haulers (dump trucks). It is responsible for powering critical functions such as steering, dump mechanisms, and attachments during heavy-duty off-road transport.

Compatible Volvo Models

This part is a standard replacement for several generations of Volvo trucks, including:

F-Series: A25F, A30F, A35F, A40F.

G-Series: A25G, A30G, A35G, A40G.

E-Series: A35E, A40E.

Technical Specifications

Pump Type: Axial Piston / Variable Displacement.

Weight: Approximately 28kg

Material: High-strength metal housing with corrosion-resistant finishes.

Mounting: Gear-driven hydraulic pump designed for direct OEM replacement.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879