SPARKLING Bobcat Cooling System Parts – Durable & Reliable

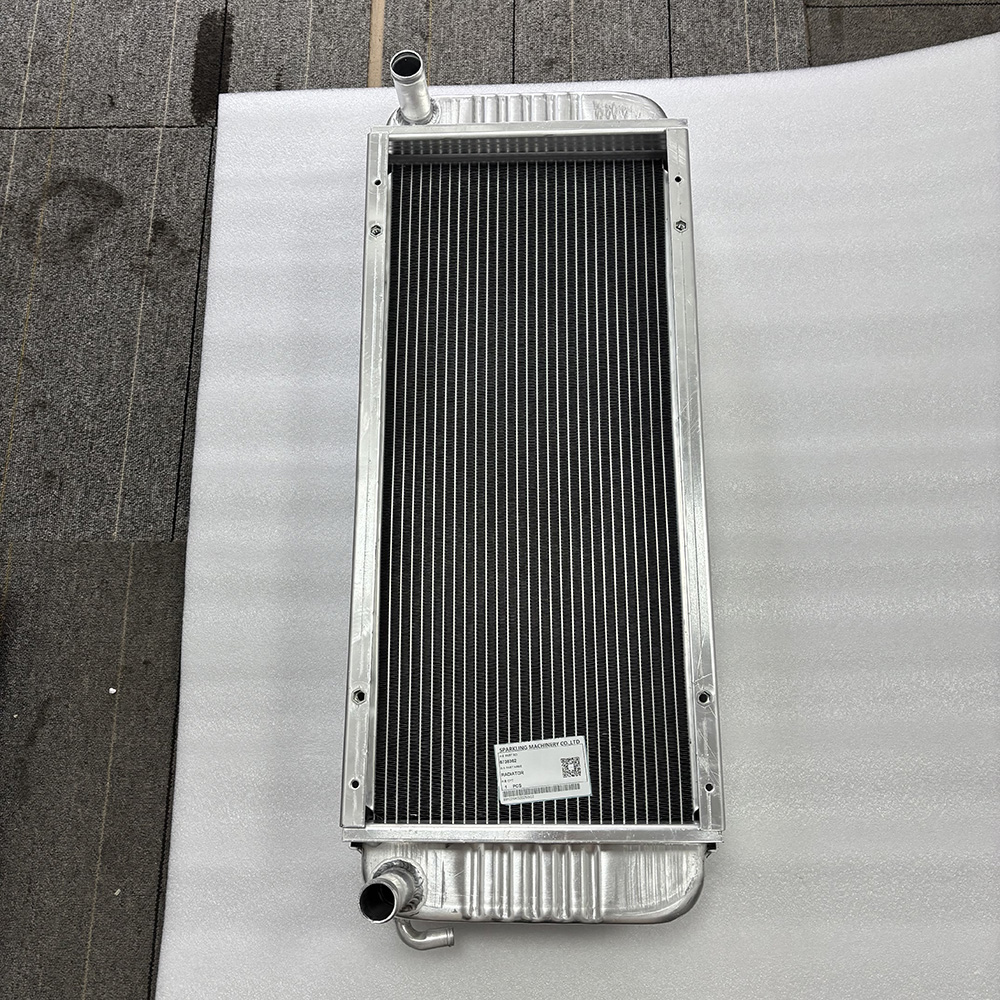

he BOBCAT 6736362 Radiator from SPARKLING MACHINERY is a high-performance cooling component specifically designed for Bobcat compact equipment. Engineered to match OEM specifications, this radiator ensures optimal engine cooling and long-lasting durability under heavy-duty working conditions.

Whether you're dealing with demanding job sites or routine operation, this China-made radiator provides exceptional heat dissipation to protect your engine and reduce the risk of overheating. The aluminum core structure, precision-welded tanks, and leak-tested design make it a reliable, cost-effective replacement for your original Bobcat 6736362 radiator.

Discover the reliability and performance of SPARKLING’s Bobcat cooling system parts, designed to keep your excavators running smoothly under demanding conditions. SPARKLING MACHINERY, established in 2013, is your trusted partner for high-quality excavator parts, specializing in components that ensure stability, precision, and longevity. Our Bobcat cooling system parts are engineered with meticulous craftsmanship and rigorous quality control to optimize heat dissipation, prevent overheating, and extend the life of your machinery.

SPARKLING’s commitment goes beyond providing parts — we offer tailored solutions and technical support that address your specific needs. Whether you're maintaining older models or upgrading your fleet, our cooling system parts are compatible with Bobcat machines, delivering dependable performance at a competitive price. We understand how vital efficient cooling is to excavator function and focus on delivering parts that protect your investment while minimizing downtime.

Backed by a global sales network and our dedication to innovation and customer care, choosing SPARKLING means you receive not only superior products but also attentive service and expert consultation. Our broad product range complements the Bobcat cooling system, helping you manage hydraulic components, engine parts, and electrical systems seamlessly. Trust SPARKLING to reduce your operational costs without sacrificing quality, helping you maintain peak productivity every day.

Product Images

Frequently Asked Questions

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

SPARKLING MACHINERY BOBCAT 6736362 RADIATOR

he BOBCAT 6736362 Radiator from SPARKLING MACHINERY is a high-performance cooling component specifically designed for Bobcat compact equipment. Engineered to match OEM specifications, this radiator ensures optimal engine cooling and long-lasting durability under heavy-duty working conditions.

Whether you're dealing with demanding job sites or routine operation, this China-made radiator provides exceptional heat dissipation to protect your engine and reduce the risk of overheating. The aluminum core structure, precision-welded tanks, and leak-tested design make it a reliable, cost-effective replacement for your original Bobcat 6736362 radiator.

ZGAQ-02033 Piece-Thrust Compatible with Hyundai Wheel Excavators R140W-7 / R140W-9 / HW140 / DX140W

The ZGAQ-02033 Piece-Thrust is a genuine Hyundai Construction Equipment (HCE) spare part used in the transmission coupling assembly of various Hyundai wheel excavators.

Key Features

· OEM direct-fit design: Exact replication of original dimensions, thickness, and mounting clearances for Hyundai R140W-7/R140W-9/HW140/DX140W—plug-and-play installation without modifications.

· Axial load absorption: Precision-engineered to bear and distribute axial forces, protecting gears and bearings from excessive thrust damage during heavy-duty operation.

· Low-friction wear resistance: High-carbon alloy steel with heat treatment and ground surfaces (Ra ≤ 0.8μm) reduce friction coefficient, minimizing power loss and component wear.

Compatible Models: This part fits a wide range of Hyundai wheel excavators, including:

· 7-Series: R140W-7, R140W-7A, R170W-7, R170W-7A, R200W-7, R200W-7A.

· 9-Series: R140W-9, R140W-9A, R140W-9S, R160W-9A, R170W-9, R170W-9S, R180W-9A, R180W-9S, R210W-9, R210W-9A, R210W-9S.

· HW-Series: HW140, HW210.

· Other models like DX140W.

Fuel Level Sender for Caterpillar 422E 428E 432E 442E – CA3032933 303-2933 3032933

Product Specifications

Part Name: Sender As - Fuel Level

Material: Features steel pipes and a plastic flange for durability and corrosion resistance.

Dimensions:

Overall Height: ~256 mm (10.08 in).

Overall Length: ~456 mm (17.95 in).

Connector Type: Uses a 2-pin DT connector.

Function: This float mechanism adjusts its position based on the fuel level, sending corresponding signals to the fuel gauge.

Key Features

OEM-Compatible Fit: Direct replacement for Caterpillar part numbers CA3032933 / 303-2933 / 3032933, ensuring precise fit and function.

Accurate Fuel Monitoring: Provides reliable, real-time fuel level readings to the gauge.

Durable Construction: Designed to withstand harsh operating conditions, including vibrations, heat, and fuel exposure.

Easy Installation: Plug-and-play design simplifies replacement and maintenance.

Long Service Life: High-quality materials and engineering ensure extended durability in heavy-duty applications.

31N5-15011 Hydraulic Main Pump for Hyundai Excavators | SPARKLING MACHINERY

The 31N5-15011 hydraulic main pump assembly is a critical hydraulic component widely used in Hyundai wheel excavators and related construction machinery. As the main power source of the hydraulic system, this pump draws hydraulic oil from the tank, pressurizes it, and delivers stable flow to drive the boom, arm, bucket, and other working functions efficiently.

This hydraulic main pump is typically designed as a variable displacement axial piston pump, allowing the excavator to automatically adjust output according to different working conditions. It is commonly used as a replacement for Kawasaki K5V80DTP hydraulic pumps, including versions with PTO output shafts, ensuring smooth operation, high efficiency, and reliable performance in heavy-duty applications.

The 31N5-15011 / 31N515011 part numbers are often used interchangeably to refer to the same hydraulic pump assembly. This pump is mainly applied to Hyundai R170W series wheel excavators, such as R170W-7, R170W-7A, and R170W-9, and is suitable for high-load construction environments where durability and consistent hydraulic power are required.

With a robust structure and an approximate weight of 102.8 kg, the 31N5-15011 hydraulic main pump is designed to work seamlessly with hydraulic motors, control valves, and hydraulic pipelines, helping improve overall machine efficiency and operating stability.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879