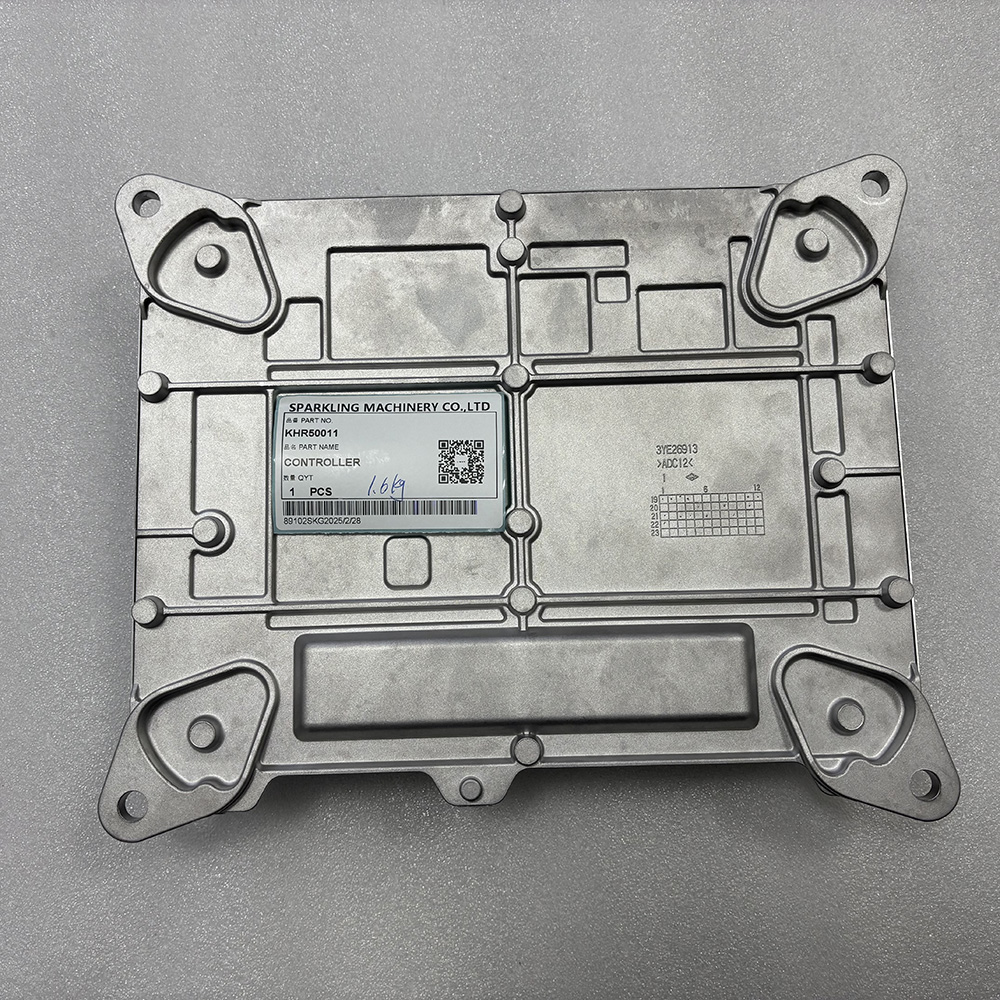

SPARKLING CASE CX490DLC ECU – Reliable Excavator Control Unit

The KHR-series Electronic Control Units (ECUs) are advanced engine and hydraulic control modules specially designed for CASE CX-series crawler excavators, including CX130DLC, CX250DLC, CX300DLC, and CX490DLC. These ECUs—part numbers KHR50000 to KHR50017—manage core operational functions such as engine response, fuel injection, hydraulic system regulation, and machine diagnostics, ensuring smooth operation, fuel efficiency, and maximum productivity on-site. Engineered for OEM-level compatibility and reliability, each unit is: Pre-programmed and ready for installation

SPARKLING CASE CX490DLC ECU – Precision Control for Maximum Excavator Performance

SPARKLING Machinery, established in 2013, proudly presents the CASE CX490DLC ECU—an advanced electronic control unit designed to optimize your excavator’s performance with unmatched precision and reliability. Developed with cutting-edge technology and strict quality standards, the SPARKLING CASE CX490DLC ECU ensures seamless engine and hydraulic system management, delivering superior fuel efficiency, enhanced operational stability, and reduced downtime.

Manufactured under rigorous quality control protocols, this ECU is engineered for durability and consistent performance across various working conditions. Compatible with CASE CX490DLC excavators, it integrates perfectly into your machine’s electrical system, guaranteeing reliable communication between engine components and hydraulic controls. Whether you are tackling heavy-duty construction or precision earthmoving, the SPARKLING CASE CX490DLC ECU supports your equipment to operate at peak capability.

With a heritage of expertise in excavator parts and a commitment to excellence, SPARKLING MACHINERY offers comprehensive support including customized technical solutions and attentive consultation. Our global sales network ensures timely delivery and responsive after-sales service, making us a trusted partner in the industry. By choosing SPARKLING, you gain a high-quality product at a competitive price, designed to reduce operational costs and increase your machine’s lifecycle.

Choose the SPARKLING CASE CX490DLC ECU for a reliable, efficient, and durable electronic control solution engineered to elevate your excavator’s performance and productivity.

Product Image

Frequently Asked Questions

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

If you have any questions about our goods or services, please feel free to contact us.

CX130DLC CX300DLC CX490DLC CX250DLC CRAWLER EXCAVATOR KHR50000 KHR50008 KHR50009 KHR50011 KHR50013 KHR50014 KHR50015 KHR50017 ELECTRONIC CONTROL UNIT

The KHR-series Electronic Control Units (ECUs) are advanced engine and hydraulic control modules specially designed for CASE CX-series crawler excavators, including CX130DLC, CX250DLC, CX300DLC, and CX490DLC. These ECUs—part numbers KHR50000 to KHR50017—manage core operational functions such as engine response, fuel injection, hydraulic system regulation, and machine diagnostics, ensuring smooth operation, fuel efficiency, and maximum productivity on-site. Engineered for OEM-level compatibility and reliability, each unit is: Pre-programmed and ready for installation

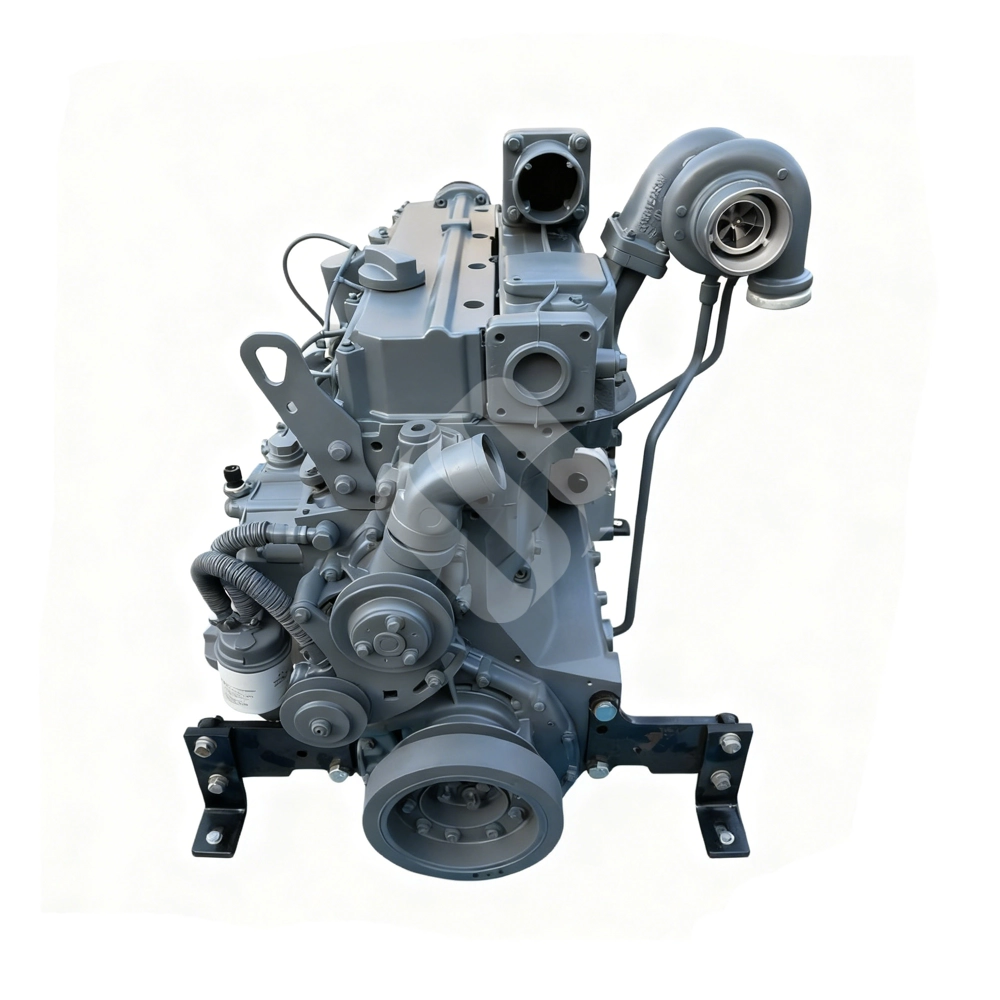

DEUTZ BF4M1012 Diesel Engine Assembly - High-Efficiency & Reliable Industrial Power Solution

Wheel Loader 423-22-32662 PLANET CARRIER FOR WA380-5 WA380-6 WA430-5 WA400-5 WA380-7 WA380-8

The 423-22-32662 planet carrier from SPARKLING MACHINERY is a durable, OEM-compatible component for Komatsu WA380 wheel loaders. Made from heat-treated alloy steel with precision-machined teeth, it ensures reliable power transmission in tough job sites. Fast global shipping and factory pricing are available.

ZGAQ-01202 & ZGAQ-01207 Axle Assembly Compatible with Hyundai Wheel Excavators R200W-7, R200W-7A, R210W-9

ZGAQ-01202 (Front Axle) and ZGAQ-01207 (Rear Axle) are OEM-compatible drive axle assemblies, the core of the travel system for Hyundai R200W-7, R200W-7A, and R210W-9 wheel excavators. They deliver 18–22 kN·m drive torque and support a maximum travel speed of 33 km/h, ensuring stable, efficient mobility and load-bearing capacity in construction, road maintenance, and urban infrastructure projects.

Key Features

· OEM direct-fit design: Exact replication of mounting points, spline dimensions, and hydraulic interfaces—plug-and-play installation without modifications for Hyundai R200W-7/R200W-7A/R210W-9.

· High-torque & load-bearing: Heavy-duty differential and planetary gear train maintain 18–22 kN·m drive torque, supporting 20.5-ton operating weight and 33 km/h travel speed.

· Durable construction: High-strength cast steel housing, 20CrMnTi hardened gears, and NBR oil seals resist wear, corrosion, and impact.

Compatible Machines:Hyundai R200W-7, R200W-7A, R210W-9 Wheel Excavators

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879