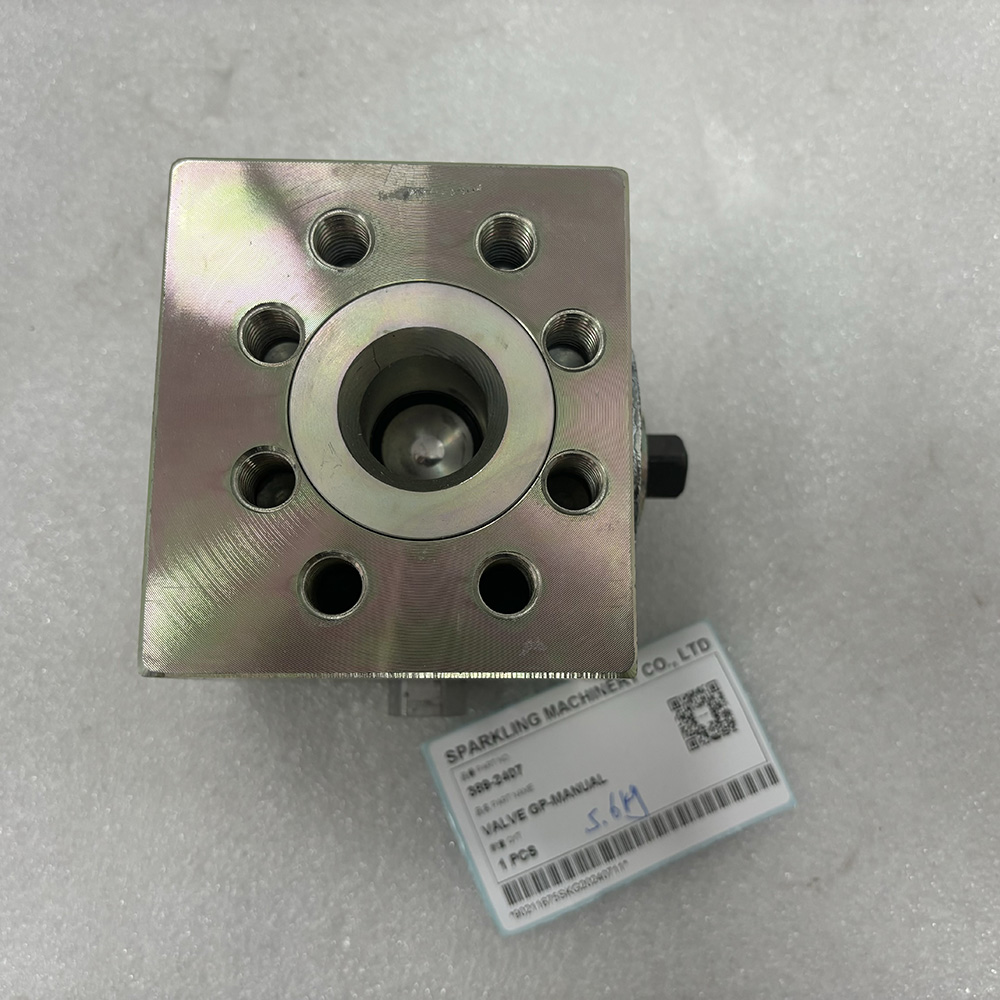

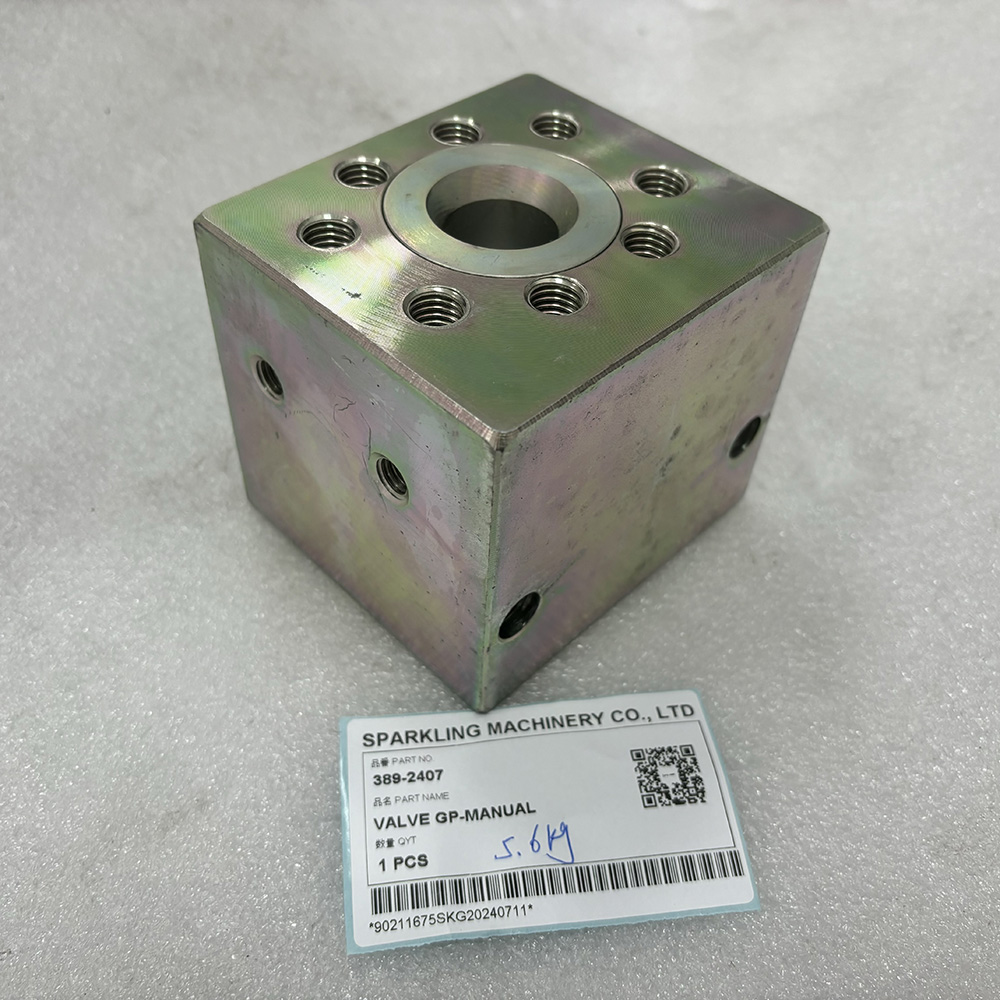

SPARKLING Cat 323F Valve – Reliable Excavator Hydraulic Component

The Valve GP‑Manual (Cat part no. 389‑2407 / CA3892407) is a rugged manual auxiliary shut‑off valve designed for use in heavy-duty Caterpillar excavators—specifically models 352, 323F, 320C, 320D SA, M325D MH/L, 355, and more. It provides dependable two-way hydraulic shut-off control, helping protect critical systems during maintenance or attachments handling. Built to OEM tolerance, this valve ensures reliable operation in the harshest environments, available both as a genuine Cat part and high-quality aftermarket alternative.

Introducing the SPARKLING Cat 323F Valve – engineered for excellence and built to last. As a flagship product from SPARKLING MACHINERY, a trusted name in excavator parts since 2013, this valve embodies our commitment to stability, precision, and durability. Designed specifically for the Cat 323F excavator, it ensures optimal hydraulic performance, enabling smooth, reliable, and efficient operations even in the most demanding environments.

Crafted using advanced manufacturing processes and subjected to rigorous quality controls, the SPARKLING Cat 323F valve guarantees long-lasting performance and resistance to wear. Its precise engineering optimizes fluid flow control, reducing downtime and maintenance costs substantially. Compatible with a wide range of excavators, including Caterpillar, Komatsu, Hitachi, and Volvo, this valve is part of our extensive lineup tailored to various hydraulic needs.

At SPARKLING MACHINERY, we prioritize customer satisfaction by offering customized solutions and dedicated technical support. Our global sales network ensures prompt delivery and continuous after-sales service, reinforcing our dedication to your success. Choosing the SPARKLING Cat 323F valve means investing in High Quality quality at competitive prices, backed by a company that values innovation, altruism, and sustainability.

Elevate your excavator's hydraulic system with the SPARKLING Cat 323F valve — where power meets precision, and reliability drives productivity.

Product Images

Q&A

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Valve GP‑Manual 389‑2407 for Cat 352 / 323F / 320C / 320D / M325D / 355 Excavators

The Valve GP‑Manual (Cat part no. 389‑2407 / CA3892407) is a rugged manual auxiliary shut‑off valve designed for use in heavy-duty Caterpillar excavators—specifically models 352, 323F, 320C, 320D SA, M325D MH/L, 355, and more. It provides dependable two-way hydraulic shut-off control, helping protect critical systems during maintenance or attachments handling. Built to OEM tolerance, this valve ensures reliable operation in the harshest environments, available both as a genuine Cat part and high-quality aftermarket alternative.

Construction Spare Parts VOE114589235/14524582 VALVE for Volvo Construction Equipment EC120D EC140B EC140C EC140D EW145B EW205D

SPARKLING MACHINERY NEW EC140B EC140C EC160B EC160C EC180B EC180C VOE114589235/14524582 Valve is a dedicated, high-precision hydraulic control component exclusively engineered for VOLVO EC140B/EC140C, EC160B/EC160C, and EC180B/EC180C crawler excavators—versatile mid-sized equipment widely used in construction, municipal engineering, and light mining projects. As a core part of the excavator’s hydraulic system, it precisely regulates the flow direction and pressure of hydraulic oil to key operational mechanisms (boom, arm, bucket), ensuring smooth, responsive, and synchronized movement during tasks like trench digging, material loading, and site grading. This function is critical for maintaining stable hydraulic performance, preventing operational lags or uneven force distribution, and avoiding costly downtime caused by hydraulic system malfunctions.

Engineered to meet VOLVO’s original equipment (OEM) standards and compatible with dual part numbers VOE114589235 and 14524582, the valve withstands harsh working conditions: high hydraulic pressure (up to 36 MPa), extreme temperature fluctuations (-25°C to 105°C), and continuous vibration from heavy-duty use. It resists oil contamination, mechanical wear, and corrosion, maintaining long-lasting control accuracy. Backed by strict performance verification, it guarantees seamless compatibility and reliable operation for all six VOLVO excavator models.

Excavator Spare Parts 5V-12V DC VOE20482772 SENSOR for Volvo Construction Equipment Excavators EC160 EC160B EC180B Wheel Loaders L60E L70E L90E

The Excavator Spare Parts 5V-12V DC VOE20482772 SENSOR is a premium multi-voltage sensing component for Volvo excavators and wheel loaders. It delivers accurate operational data, adapts to dual voltage ranges, integrates seamlessly, and performs reliably in harsh construction environments.

Key Features

· Dual voltage compatibility (5V-12V DC) for versatile equipment adaptation

· Custom-engineered for Volvo EC-series excavators and L-series wheel loaders

· High-precision data detection for real-time system feedback

Vibration, dust, and extreme temperature resistant design

· Strict adherence to Volvo OEM specifications for consistent functionality

Compatible Models

· Volvo Construction Equipment Excavators: EC160, EC160B, EC180B

Volvo Construction Equipment Wheel Loaders: L60E, L70E, L90E

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW A35E EC330B EC330C EC360B L220F PL4608 VOE21243114 ROCKER SPARKLING MACHINERY

SPARKLING MACHINERY NEW A35E EC330B EC330C EC360B L220F PL4608 VOE21243114 Rocker is a key operational component for 6 Volvo heavy equipment models (mining/construction use). It enables precise actuation of core functions (e.g., hydraulic controls, auxiliary operations) with responsive performance, ensuring smooth equipment maneuvering.

Meeting Volvo OEM standards (VOE21243114), it resists -30°C to 85°C temps, wear, and vibration, guaranteeing seamless compatibility and long-term reliable operation.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879