SPARKLING Cat Hydraulic Shut-Off Valve – Precision & Durability

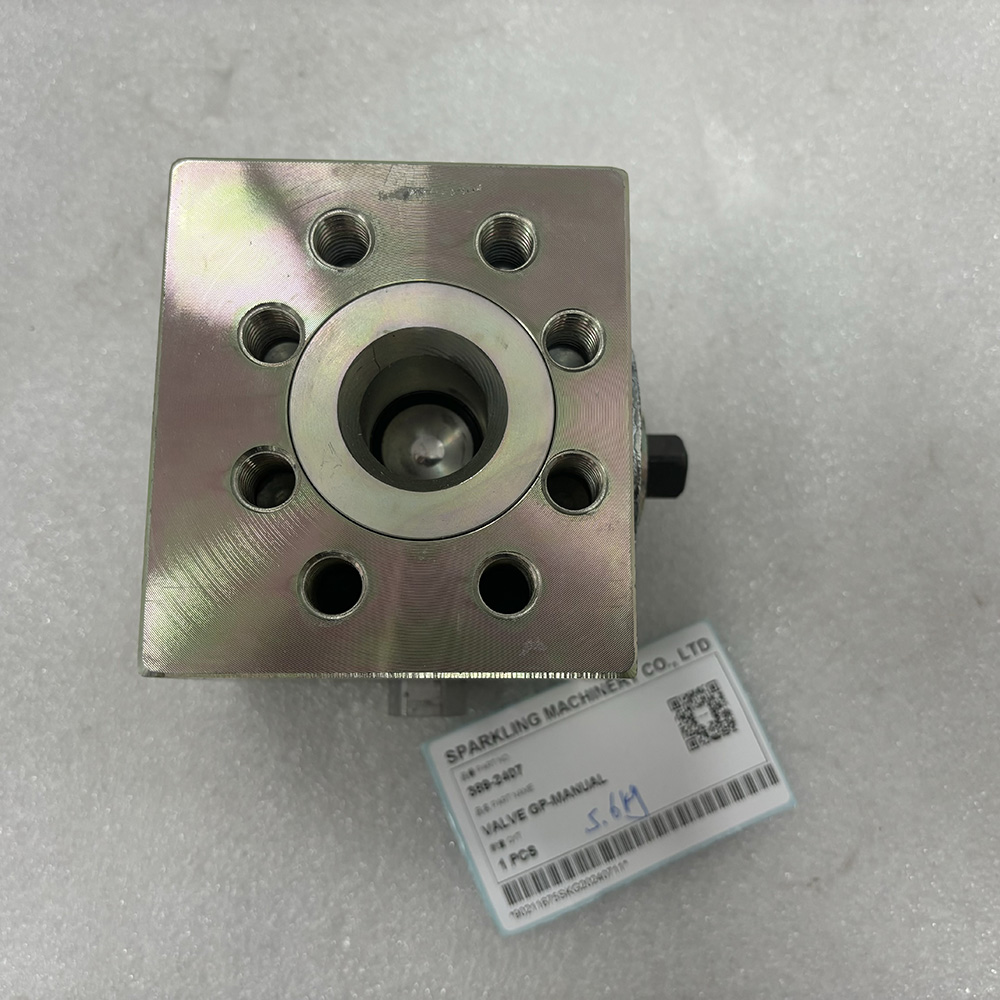

The Valve GP‑Manual (Cat part no. 389‑2407 / CA3892407) is a rugged manual auxiliary shut‑off valve designed for use in heavy-duty Caterpillar excavators—specifically models 352, 323F, 320C, 320D SA, M325D MH/L, 355, and more. It provides dependable two-way hydraulic shut-off control, helping protect critical systems during maintenance or attachments handling. Built to OEM tolerance, this valve ensures reliable operation in the harshest environments, available both as a genuine Cat part and high-quality aftermarket alternative.

SPARKLING Cat Hydraulic Shut-Off Valve: Precision and Reliability You Can Trust

SPARKLING MACHINERY, established in 2013, proudly presents the Cat hydraulic shut-off valve, engineered to meet the highest standards of performance and durability. Designed specifically for Caterpillar excavators, our valve ensures optimal hydraulic flow control, enhancing machine efficiency and safety in demanding environments.

Manufactured with precision and rigorously tested, the SPARKLING Cat hydraulic shut-off valve guarantees stable operation even under extreme pressure and wear. Our commitment to quality and stability means your excavator’s hydraulic system experiences reduced downtime and prolonged service life. With SPARKLING, you receive not just a part but a reliable component that supports your machinery’s peak performance.

At SPARKLING MACHINERY, we combine advanced manufacturing techniques with thorough quality control to deliver components compatible with major brands such as Caterpillar, Komatsu, Hitachi, and Volvo. Our Cat hydraulic shut-off valve exemplifies our dedication to stability, precision, and perseverance — values that have helped us become a trusted name in the excavator parts industry worldwide.

We also offer customized solutions and professional technical support, ensuring seamless integration and continuous service. SPARKLING provides competitive pricing without compromising on quality, helping you reduce operational costs while maintaining reliability. Partner with SPARKLING MACHINERY for your hydraulic component needs and experience peace of mind with every excavator project.

Product Image

Question you may concern

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Valve GP‑Manual 389‑2407 for Cat 352 / 323F / 320C / 320D / M325D / 355 Excavators

The Valve GP‑Manual (Cat part no. 389‑2407 / CA3892407) is a rugged manual auxiliary shut‑off valve designed for use in heavy-duty Caterpillar excavators—specifically models 352, 323F, 320C, 320D SA, M325D MH/L, 355, and more. It provides dependable two-way hydraulic shut-off control, helping protect critical systems during maintenance or attachments handling. Built to OEM tolerance, this valve ensures reliable operation in the harshest environments, available both as a genuine Cat part and high-quality aftermarket alternative.

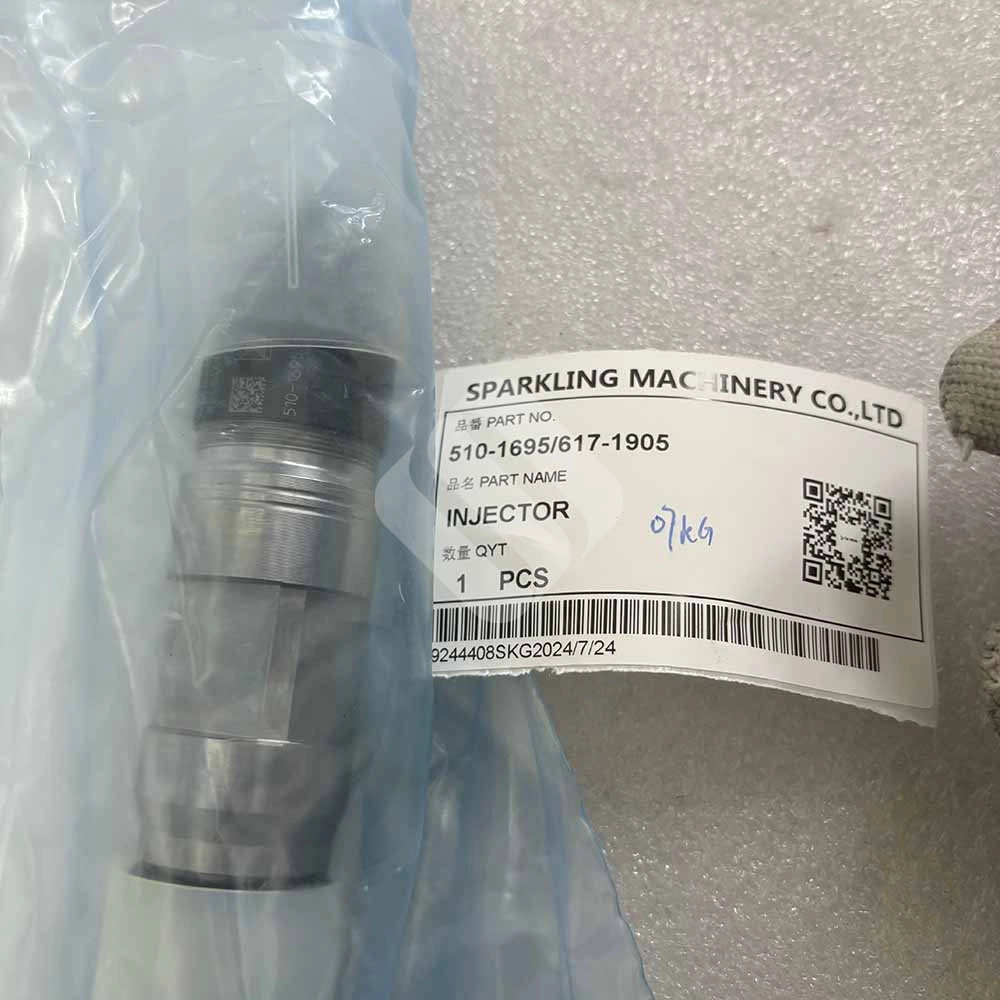

Caterpillar EXCAVATOR PARTS MADE IN CHINA NEW 336GC 340GC 345GC 350GC 510-1695/617-1905 INJECTOR SPARKLING MACHINERY

SPARKLING MACHINERY NEW 336GC 340GC 345GC 350GC 510-1695/617-1905 Injector is a core engine fuel injection component for Caterpillar 336GC, 340GC, 345GC, and 350GC excavators (widely used in heavy construction, mining, and large-scale infrastructure projects). As the "fuel atomization core", it precisely sprays fuel into the combustion chamber—ensuring efficient fuel combustion during high-intensity tasks like rock breaking, deep digging, and heavy lifting, while maintaining stable engine power output and reducing fuel waste.

Meeting Caterpillar OEM standards (part nos. 510-1695/617-1905), it endures -30°C to 200°C engine temperatures, resists fuel corrosion and vibration, and guarantees consistent injection pressure. Strict testing ensures seamless compatibility with the four Caterpillar models and long-term engine reliability.

KOMATSU HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW D155AX D65EX D65PX HB205 HB215 ND116420-7450 HEATER CORE SPARKLING MACHINERY

SPARKLING MACHINERY NEW ND116420-7450 Heater Rad Set is a core climate control assembly for Komatsu D155AX/D65EX/D65PX/HB205/HB215 excavators (construction/mining use). It integrates a heater radiator and matching components, heating cabin air via engine coolant circulation to ensure comfortable and safe operation in low temperatures.

Excavators: PC200-7, PC200-8M0, PC210, PC220-8M0, PC300-8M0, PC350-8.

Bulldozers/Loaders: D155AX, D65EX

Atlas Copco HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 1089037601 TEMPERATURE SWITCH SPARKLING MACHINERY

SPARKLING MACHINERY's new 1089037601 Temperature Switch is a core sensing component specifically designed for Atlas Copco excavators, suitable for construction and mining applications. It monitors the temperature of key systems (e.g., engine, hydraulic oil) in real time and triggers protection mechanisms when overheating occurs.

Compliant with Atlas Copco OEM standards (Part No.: 1089037601), this component exhibits excellent temperature sensing accuracy and operational stability, ensuring seamless compatibility with original equipment and long-term safe operational performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879