SPARKLING Cat OEM Radiator – Reliable Cooling for Excavators

The SEM Radiator 539‑1100 is a durable cooling system designed for SEM and Caterpillar machinery. Precisely engineered by Cat, this radiator maintains optimal engine temperature under heavy-duty conditions. Featuring premium materials and OEM-grade construction, it delivers enhanced corrosion resistance and long-term reliability—backed by Cat’s global parts support network

Discover the SPARKLING Cat OEM Radiator — engineered for superior cooling performance and unmatched durability in your excavator. As part of SPARKLING MACHINERY’s trusted lineup, this radiator is precisely manufactured to meet Cat’s rigorous OEM standards, ensuring perfect compatibility and reliable operation under demanding conditions.

Since 2013, SPARKLING MACHINERY has specialized in high-quality excavator parts, emphasizing stability, precision, and perseverance. Our Cat OEM radiator benefits from strict quality control and advanced manufacturing techniques, delivering excellent heat dissipation to keep your engine running at optimal temperatures. Whether you work in extreme climates or tough terrains, this radiator maintains consistent cooling performance, preventing overheating and prolonging engine life.

Compatible with various Cat excavator models, the SPARKLING radiator offers a hassle-free replacement solution that minimizes downtime. We also provide customized options and expert technical support to meet your unique needs. With our commitment to innovation, altruism, and competitive pricing, SPARKLING MACHINERY stands out as a reliable partner for hydraulic components, undercarriage systems, engine parts, and more — trusted by operators worldwide.

Choose the SPARKLING Cat OEM radiator for dependable quality, excellent value, and peace of mind. Enhance your excavator’s performance today with a product designed to reduce maintenance costs and maximize efficiency.

Detailed display

Q&A

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

If you have any questions or concern, please contact us.

SEM Radiator 539‑1100 – OEM Cat Cooling System for Heavy Equipment

The SEM Radiator 539‑1100 is a durable cooling system designed for SEM and Caterpillar machinery. Precisely engineered by Cat, this radiator maintains optimal engine temperature under heavy-duty conditions. Featuring premium materials and OEM-grade construction, it delivers enhanced corrosion resistance and long-term reliability—backed by Cat’s global parts support network

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 307D 312D 312D2 313D2 320D 245-7836 EVAPORATOR SPARKLING MACHINERY

SPARKLING MACHINERY NEW 245-7836 Evaporator is a core climate control component for Caterpillar 307D/312D/312D2/313D2/320D excavators (construction/mining use). It realizes cabin cooling by evaporating refrigerant in the air conditioning system, ensuring comfortable operating conditions in high temperatures.

Meeting Caterpillar OEM standards (245-7836), it resists -30°C to 120°C temps, corrosion, and moisture, guaranteeing seamless compatibility and reliable long-term refrigeration performance.

KOMATSU HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW BR200S BR550JG BR580JG PC270 PC270LL 702-75-04600 RELIEF VALVE SPARKLING MACHINERY

SPARKLING MACHINERY NEW BR200S BR550JG BR580JG PC270 PC270LL 702-75-04600 Relief Valve is a core hydraulic safety component for Komatsu BR200S/BR550JG/BR580JG/PC270/PC270LL excavators (heavy-duty construction/mining use). It regulates and limits maximum hydraulic system pressure to prevent overload damage to pumps, hoses, and actuators.

Meeting Komatsu OEM standards (702-75-04600), it resists -30°C to 100°C temps, pressure fluctuations, and contamination, ensuring seamless compatibility and long-term reliable pressure protection.

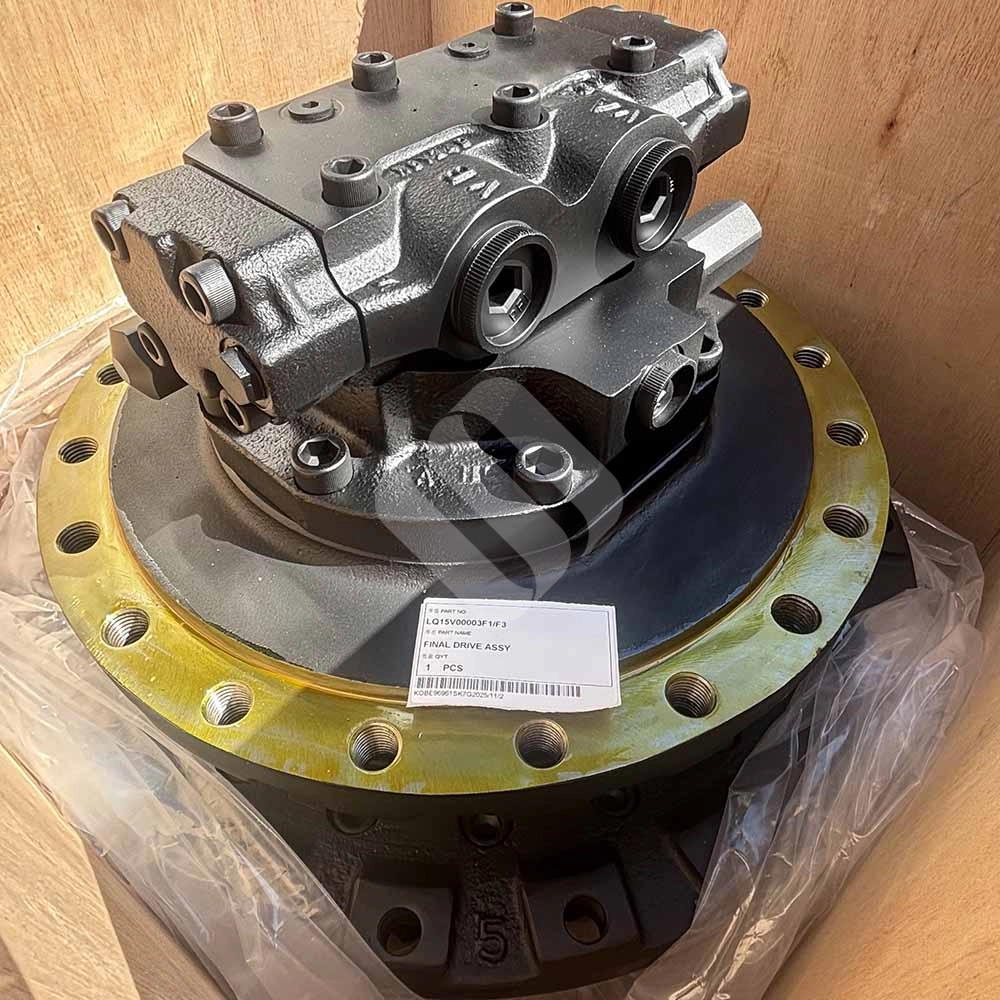

Final Drive Assy for Kobelco Excavator SK250NLC SK220LC SK250LC LQ15V00003F1 LQ15V00003F3 From SPARKLING MACHINERY

SPARKLING MACHINERY NEW SK250NLC SK220LC SK250LC LQ15V00003F1/F3 Final Drive Assy is a core power transmission component for 3 Kobelco excavator models (construction/mining use). It converts hydraulic energy to rotational force for track movement, ensuring stable traction during heavy-load tasks.

Meeting Kobelco OEM standards (dual part numbers), it resists -30°C to 100°C temps, high torque, and wear, guaranteeing seamless compatibility and long-term reliable driving performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879