SPARKLING Caterpillar OEM Valve – Reliable Excavator Part

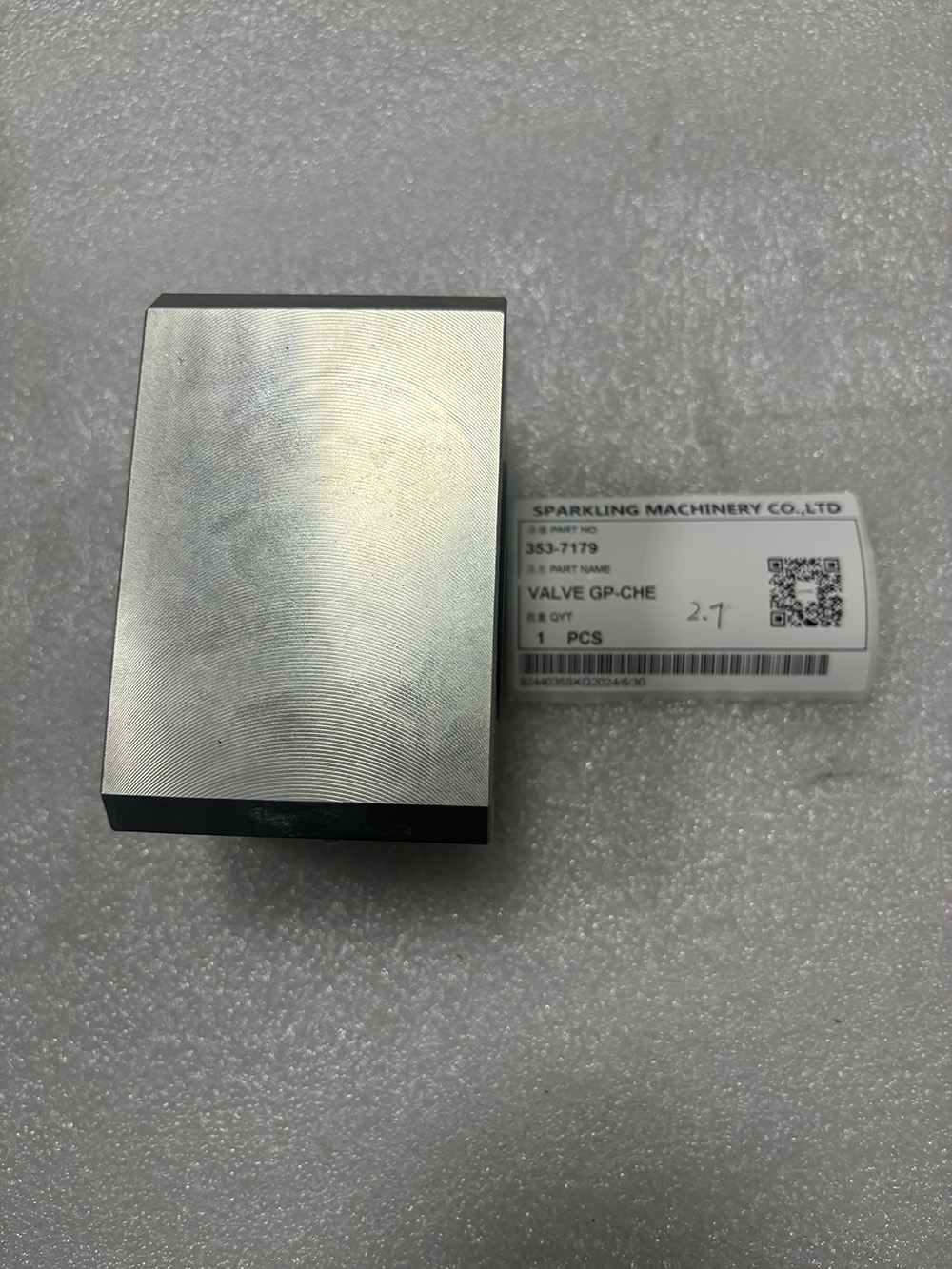

The VALVE GP‑CHECK (part no. 353‑7179 / 3537179) is a precision-engineered in-line check valve designed for heavy‑duty Caterpillar equipment—including 980, 982, 982M, 982 XE wheel loaders, and the D10T2 track‑type tractor. This valve ensures reliable hydraulic pressure control and one‑way fluid flow, crucial for maintaining system integrity and preventing backflow. Built to Cat’s exacting standards, it delivers long-lasting performance in demanding environments and is available as both genuine OEM and high-quality aftermarket options.

SPARKLING Caterpillar OEM Valve – Precision and Reliability You Can Trust

At SPARKLING MACHINERY, we understand that high-quality components are vital for your excavator’s performance. Our Caterpillar OEM valve is engineered with precision and durability, crafted to meet the exact standards of Caterpillar machinery. Since 2013, SPARKLING has specialized in producing reliable excavator parts, including hydraulic components, undercarriage systems, and engine parts, all designed to ensure optimal machine efficiency.

The SPARKLING Caterpillar OEM valve undergoes rigorous quality control, guaranteeing superior stability and long-lasting functionality even in the most demanding environments. Compatible with a wide array of Caterpillar models, this valve maintains fluid control and supports the hydraulic system’s performance, minimizing downtime and maintenance costs.

As industry professionals committed to excellence and innovation, SPARKLING MACHINERY offers customized solutions and expert technical support to meet your unique needs. Our passion for altruism drives us to deliver competitive pricing without compromising quality, helping you reduce overall operating costs.

With a global sales network and a commitment to customer satisfaction, SPARKLING MACHINERY is your trusted partner for dependable excavator parts. Choose our Caterpillar OEM valve to experience peace of mind and consistent performance in your heavy machinery operations.

Picture Show

Frequently Asked Questions

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

If you have any other questions, please write email to us or call us , we will reply you as soon as possible.

VALVE GP-CHECK 353‑7179 for Cat 980 / 982 / 982M XE Wheel Loaders & D10T2 Tractor

The VALVE GP‑CHECK (part no. 353‑7179 / 3537179) is a precision-engineered in-line check valve designed for heavy‑duty Caterpillar equipment—including 980, 982, 982M, 982 XE wheel loaders, and the D10T2 track‑type tractor. This valve ensures reliable hydraulic pressure control and one‑way fluid flow, crucial for maintaining system integrity and preventing backflow. Built to Cat’s exacting standards, it delivers long-lasting performance in demanding environments and is available as both genuine OEM and high-quality aftermarket options.

SPARKLING MACHINERY EC300D EC330B EC360B VOE14604301 14689663 VOE 14689663 SPROCKET

Thank you for exploring our Volvo Sprocket VOE14604301 and VOE14689663, expertly crafted for EC300D, EC330B, and EC360B excavators. We understand how essential a reliable undercarriage is to ensure your excavators operate safely and efficiently, day in and day out.

At SPARKLING MACHINERY, we are committed to providing premium-quality spare parts that meet or exceed OEM standards, giving you the confidence to keep your projects moving forward without costly interruptions. Our mission is to help you minimize downtime, extend equipment life, and reduce operating costs.

We truly appreciate your interest and your trust in our products. Whether you’re managing a single excavator or a large fleet, we’re here to support your success with fast delivery, technical expertise, and dedicated customer service.

💬 Have questions about compatibility, pricing, or technical details? Please don’t hesitate to reach out — our team is always ready to assist.

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EC135B EC140B EC140C EC160B EC160C VOE14564772 MIRROR SPARKLING MACHINERY

SPARKLING MACHINERY NEW EC135B EC140B EC140C EC160B EC160C VOE14564772 Mirror is a dedicated visibility component for VOLVO EC135B, EC140B, EC140C, EC160B, and EC160C crawler excavators (widely used in construction, municipal engineering, and medium-scale earthmoving). As a key part of the excavator’s cab safety system, it provides clear, wide-angle visibility of the surrounding work area—enabling operators to monitor blind spots during tasks like digging, loading, and equipment maneuvering, thus reducing collision risks.

Meeting VOLVO OEM standards (part no. VOE14564772), it endures -30°C to 85°C temperatures, resists impact, UV radiation, and dust, and maintains anti-glare clarity. Strict testing guarantees seamless compatibility with the five VOLVO models and long-term reliable visibility performance.

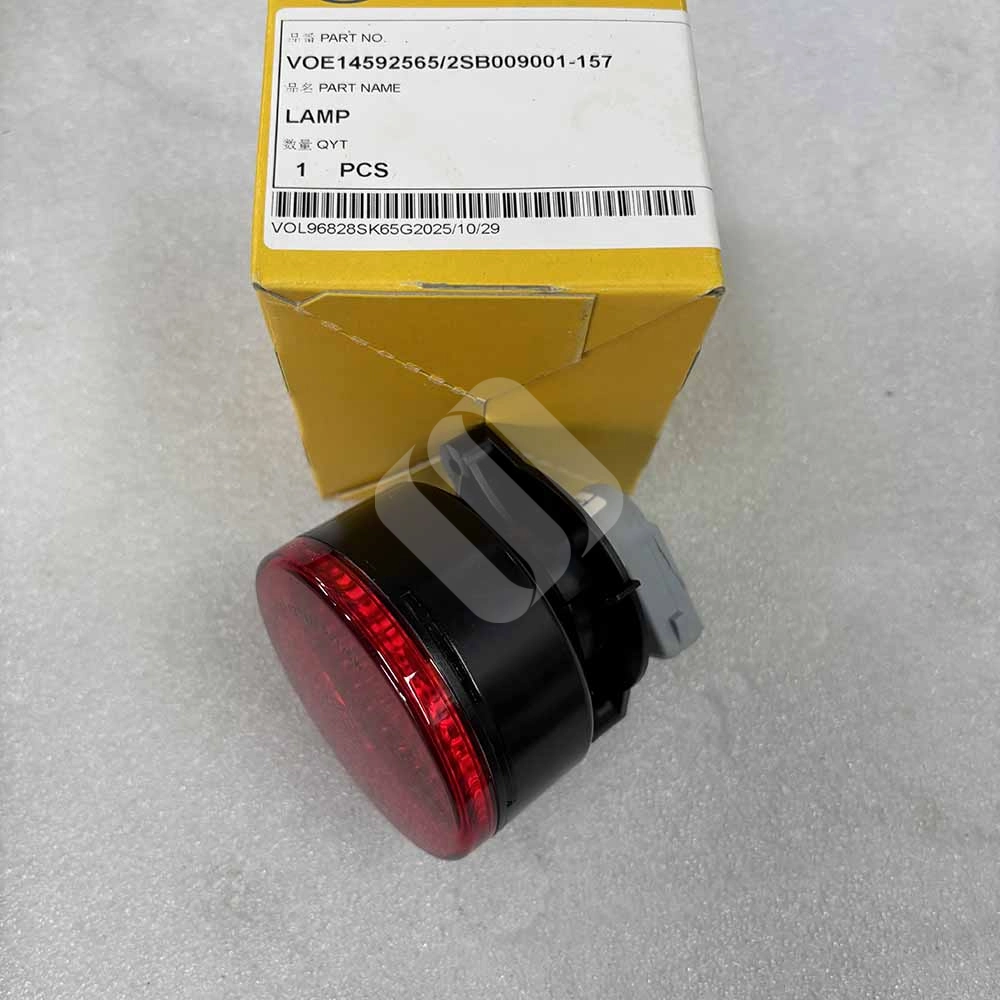

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EW140C EW145B EW160C EW180C VOE14592565/2SB009001-157 LAMP SPARKLING MACHINERY

SPARKLING MACHINERY NEW EW140C EW145B EW160C EW180C VOE14592565 2SB009001-157 Lamp is a critical lighting component for 4 Volvo excavator models (construction/municipal use). It delivers bright, stable illumination for work areas—essential for low-light/nighttime operations—to ensure operator visibility and safety.

Meeting Volvo OEM standards (VOE14592565 & 2SB009001-157), it resists -30°C to 85°C temps, moisture, and vibration, guaranteeing seamless compatibility and long-term reliable performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879