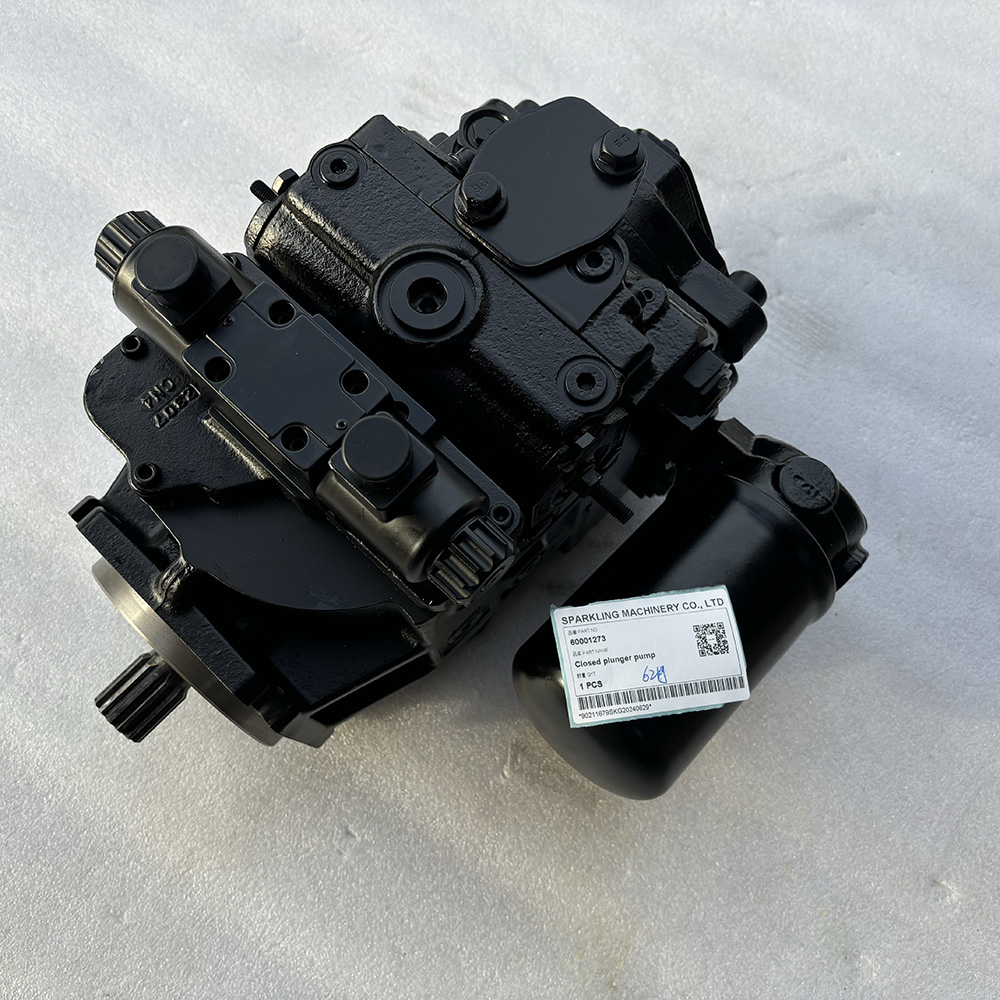

SPARKLING Closed Plunger Pump – Precision Hydraulic Solutions

The 60001273 Closed Plunger Pump is a high-performance hydraulic plunger pump designed for industrial machinery and heavy equipment applications. Featuring a closed plunger design, this pump ensures excellent sealing and durability, preventing hydraulic fluid leaks and maintaining stable system pressure. Built to withstand high-pressure environments, it delivers reliable and efficient hydraulic power, making it an ideal replacement part to keep your equipment running smoothly and effectively.

SPARKLING Closed Plunger Pump – Precision & Reliability You Can Trust

At SPARKLING MACHINERY, founded in 2013, we bring you the highest quality closed plunger pump designed specifically for excavator hydraulic systems. Our closed plunger pump is engineered to deliver exceptional stability and precise hydraulic performance, ensuring your equipment operates smoothly even in the most demanding environments.

Crafted with advanced manufacturing techniques and rigorous quality control, the SPARKLING closed plunger pump offers outstanding durability and efficient power transmission. Compatible with leading excavator brands such as Caterpillar, Komatsu, Hitachi, and Volvo, it integrates seamlessly into your hydraulic system to optimize productivity and reduce downtime.

Understanding the critical role hydraulic components play in your operations, we provide customized solutions tailored to your exact needs. Our expert team offers meticulous consultation and ongoing technical support to help you select the right pump and maintain it effectively. With SPARKLING, you gain a reliable partner committed to lowering maintenance costs while enhancing performance.

We pride ourselves on our values of altruism and innovation, ensuring every closed plunger pump delivers competitive pricing without compromising quality. Our global sales network guarantees timely delivery and customer care, making SPARKLING MACHINERY your trusted source for hydraulic components worldwide.

Choose the SPARKLING closed plunger pump for unmatched precision, reliability, and value – because your equipment deserves the best.

Product Images

Question you may concern

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

60001273 CLOSED PLUNGER PUMP

The 60001273 Closed Plunger Pump is a high-performance hydraulic plunger pump designed for industrial machinery and heavy equipment applications. Featuring a closed plunger design, this pump ensures excellent sealing and durability, preventing hydraulic fluid leaks and maintaining stable system pressure. Built to withstand high-pressure environments, it delivers reliable and efficient hydraulic power, making it an ideal replacement part to keep your equipment running smoothly and effectively.

Caterpillar EXCAVATOR PARTS MADE IN CHINA NEW M313C M313D M315C M315D 196-7486 SOLENOID VALVE SPARKLING MACHINERY

SPARKLING MACHINERY NEW M313C M313D M315C M315D 196-7486 Solenoid Valve is a key hydraulic control component for 4 Caterpillar excavator models (construction/municipal use). It regulates hydraulic oil flow direction and on/off status, ensuring precise operation of boom, bucket, and other functions. Meeting Caterpillar OEM standards (196-7486), it resists -30°C to 95°C temps, oil corrosion, and vibration, guaranteeing seamless compatibility and reliable performance.

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 301.4C 3792809 TURBOCHARGER SPARKLING MACHINERY

SPARKLING MACHINERY's new 3792809 Turbocharger is a core power-enhancing component specifically designed for Caterpillar 301.4C excavators, suitable for construction and mining applications. It enhances engine power and fuel efficiency by compressing intake air, ensuring the engine operates at optimal performance under high-load conditions. Compliant with Caterpillar OEM standards (Part No.: 3792809), this component exhibits excellent high-temperature resistance and rotational stability, ensuring seamless compatibility with original equipment and long-term reliable operational performance.

HIGH-QUALITY 2549-9112 PRESSURE SWITCH SENSOR FOR DOOSAN(DAEWOO) CONSTRUCTION EQUIPMENT DH220-5 DH215-5 DH225-5 DH220-7 DH225-7 DH300-7 EXCAVATOR

The HIGH-QUALITY 2549-9112 Pressure Switch Sensor is a premium electronic monitoring component meticulously engineered for Doosan (Daewoo) Construction Equipment, specifically tailored to meet the precision pressure detection needs of DH220-5, DH215-5, DH225-5, DH220-7, DH225-7, DH300-7, DH300-9, and DX140W excavators. As a critical part of the machinery’s hydraulic and electrical control systems, this pressure switch sensor accurately detects and transmits pressure signals in real time, enabling the excavator’s control unit to regulate system pressure, prevent overloading, and ensure safe, efficient operation in demanding construction environments.

It is designed to seamlessly integrate with Doosan (Daewoo)’s excavator architecture, delivering consistent performance that enhances machinery reliability and operational safety.

Key Features

· Custom-engineered for perfect compatibility with Doosan (Daewoo) DH220-5, DH215-5, DH225-5, DH220-7, DH225-7, DH300-7, DH300-9, DX140W excavators

· High-precision pressure detection with fast response time for real-time system monitoring

· Robust structural design resistant to vibration, moisture, dust, and extreme temperature fluctuations

· Stable electrical performance and anti-interference capability for accurate signal transmission

· Strict adherence to Doosan (Daewoo) OEM specifications for seamless integration and consistent functionality

Compatible Models

· Doosan (Daewoo) Construction Equipment Excavators: DH220-5, DH215-5, DH225-5, DH220-7, DH225-7, DH300-7, DH300-9, DX140W

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879