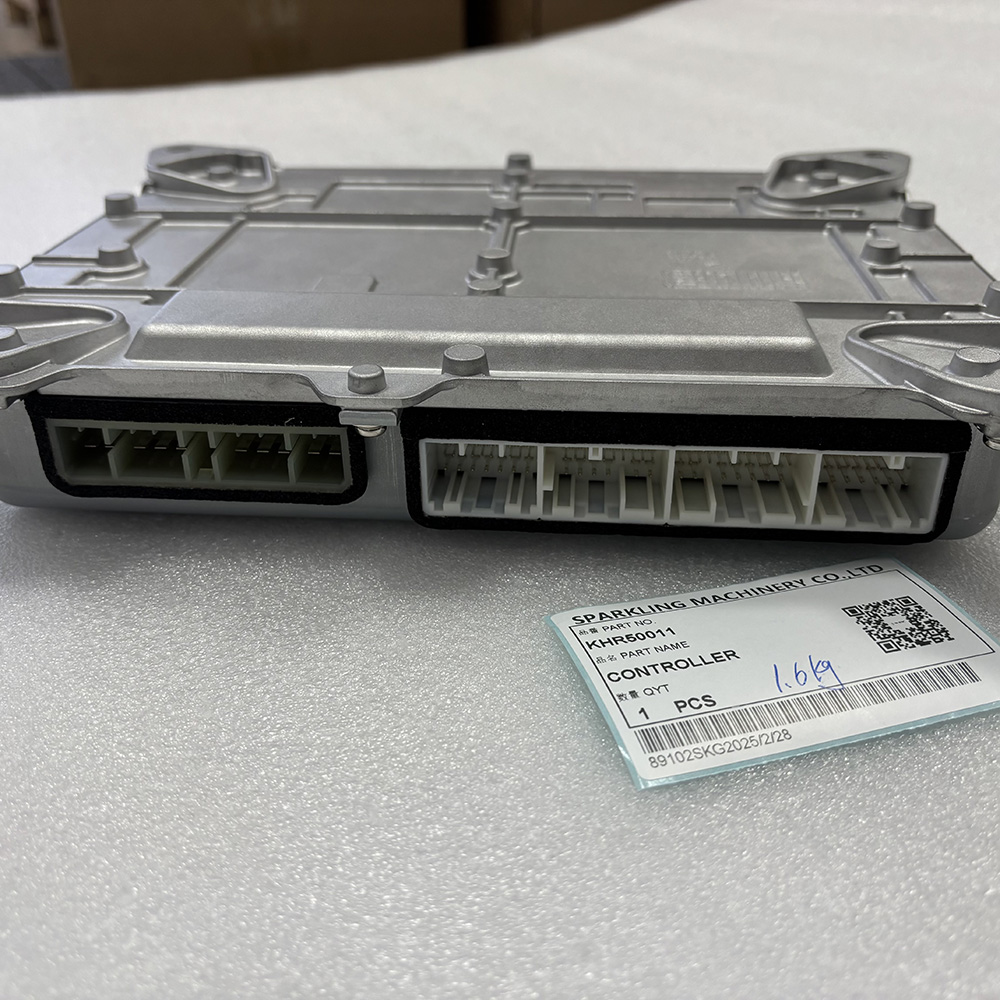

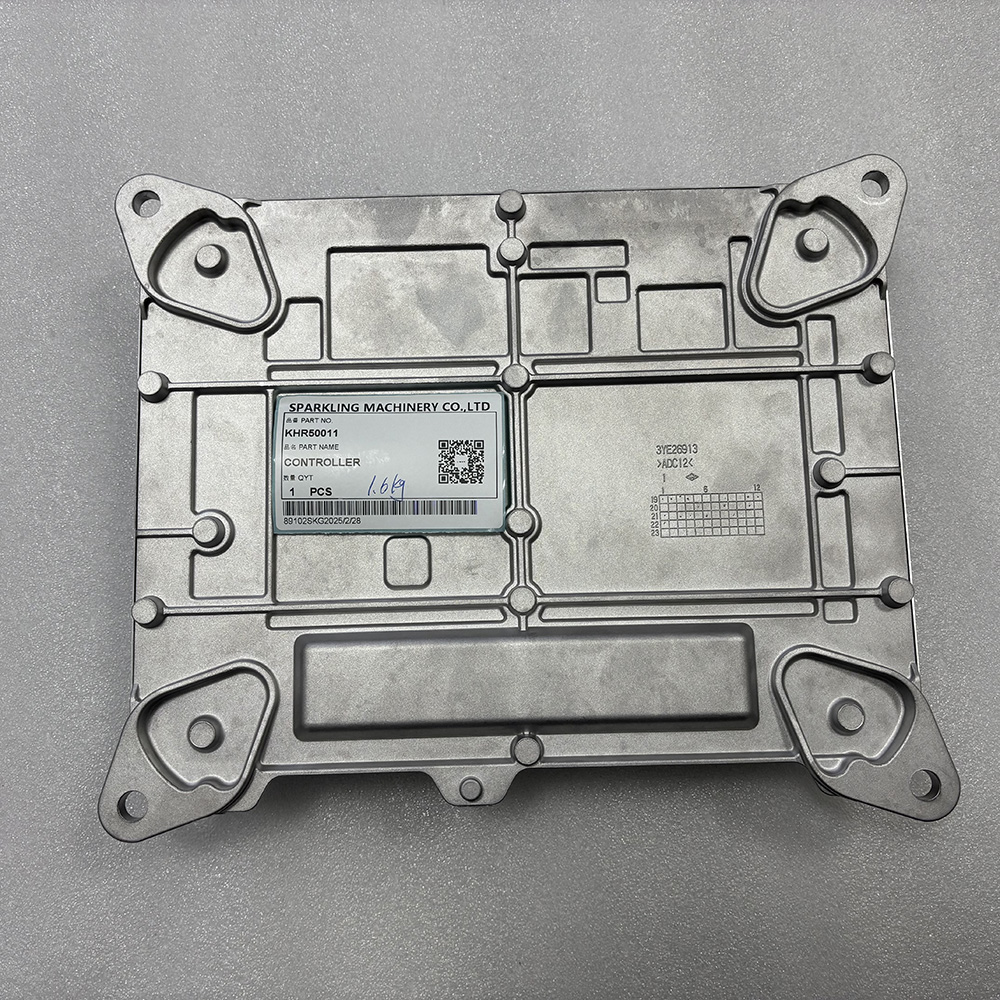

SPARKLING CX130DLC ECU – Reliable Excavator Control Unit

The KHR-series Electronic Control Units (ECUs) are advanced engine and hydraulic control modules specially designed for CASE CX-series crawler excavators, including CX130DLC, CX250DLC, CX300DLC, and CX490DLC.

These ECUs—part numbers KHR50000 to KHR50017—manage core operational functions such as engine response, fuel injection, hydraulic system regulation, and machine diagnostics, ensuring smooth operation, fuel efficiency, and maximum productivity on-site.

Engineered for OEM-level compatibility and reliability, each unit is:

-

Pre-programmed and ready for installation

Ideal for repair, replacement, or equipment upgrading, this electronic control system ensures optimal machine performance with minimal downtime.

SPARKLING CX130DLC ECU – Precision Control for Optimal Excavator Performance

The SPARKLING CX130DLC ECU is a High Quality electronic control unit designed specifically for excavators, ensuring seamless engine management and enhanced machine efficiency. Engineered with precision and durability, this ECU meets the highest standards of quality and reliability demanded by modern construction environments.

At SPARKLING MACHINERY, founded in 2013, we dedicate ourselves to producing high-quality excavator parts that deliver stability, precision, and long-lasting performance. Our CX130DLC ECU is compatible with leading excavator brands like Caterpillar, Komatsu, Hitachi, and Volvo, making it a versatile and trusted component for various models.

This ECU optimizes fuel efficiency, reduces emissions, and improves engine responsiveness, providing operators with smooth and reliable control. Manufactured under stringent quality standards, the CX130DLC ECU withstands diverse operating conditions, ensuring your excavator runs consistently and effectively on every job site.

Beyond supplying exceptional parts, SPARKLING MACHINERY offers customized solutions and expert technical support to meet your unique needs. We combine innovation with altruistic values by providing competitive pricing while maintaining superior product quality. Our global sales network guarantees accessible and responsive service wherever your projects take you.

Choose the SPARKLING CX130DLC ECU for a dependable upgrade that enhances your excavator’s performance, cuts down operational costs, and supports your equipment’s longevity. Experience the precision and trust that come from partnering with a world-class excavator parts manufacturer committed to your success.

Picture Show

Frequently Asked Questions

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

About other questions pls contact me directily.

CX130DLC CX300DLC CX490DLC CX250DLC CRAWLER EXCAVATOR KHR50000 KHR50008 KHR50009 KHR50011 KHR50013 KHR50014 KHR50015 KHR50017 ELECTRONIC CONTROL UNIT

The KHR-series Electronic Control Units (ECUs) are advanced engine and hydraulic control modules specially designed for CASE CX-series crawler excavators, including CX130DLC, CX250DLC, CX300DLC, and CX490DLC. These ECUs—part numbers KHR50000 to KHR50017—manage core operational functions such as engine response, fuel injection, hydraulic system regulation, and machine diagnostics, ensuring smooth operation, fuel efficiency, and maximum productivity on-site. Engineered for OEM-level compatibility and reliability, each unit is: Pre-programmed and ready for installation

Excavators Spare Parts 294-0286 COVER for Caterpillar Engines CAT C4.4 C6.6 C7.1 Excavator 320D, 320D L, 320D2, 320D2 GC, 320D GC

The Excavators Spare Parts 294-0286 COVER is a premium protective component meticulously engineered for Caterpillar Engines (CAT C4.4, C6.6, C7.1) and specifically tailored to meet the safeguarding demands of 320D, 320D L, 320D2, 320D2 GC, and 320D GC excavators. As a critical protective part of the machinery’s engine system, this cover shields key engine components (such as wiring harnesses, sensors, and auxiliary mechanisms) from external hazards—including dust, debris, moisture, and mechanical impact—encountered in harsh construction environments. It maintains the integrity of the engine’s sensitive parts, ensures unobstructed airflow for heat dissipation, and contributes to stable engine operation even during prolonged heavy-duty digging, lifting, or earthmoving tasks.

Designed to seamlessly integrate with Caterpillar’s engine and excavator architecture, it enhances engine reliability, extends component service life, and reduces maintenance frequency.

Key Features

· Custom-engineered for perfect compatibility with Caterpillar Engines CAT C4.4, C6.6, C7.1 and 320D-series excavators (320D, 320D L, 320D2, 320D2 GC, 320D GC)

· Robust structural design for exceptional impact resistance and long-term durability

· Optimized ventilation and fit to ensure unimpeded engine heat dissipation

· Precision-molded edges for tight sealing against dust, moisture, and debris ingress

· Strict adherence to Caterpillar OEM specifications for seamless integration and consistent protective performance

Compatible Models

· Caterpillar Excavators (Equipped with CAT C4.4 / C6.6 / C7.1 Engines): 320D, 320D L, 320D2, 320D2 GC, 320D GC

HITACHI MADE IN CHINA SPARKLING MACHINERY NEW ZX350LC-5B ZX350LCN-5B 8970241240 8943925532 GASKET

SPARKLING MACHINERY NEW ZX350LC-5B ZX350LCN-5B 8970241240 8943925532 Gasket is a dedicated sealing component exclusively designed for ZX350LC-5B and ZX350LCN-5B excavators. As a core part of the excavators’ engine, hydraulic, or fuel systems, it creates a tight, leakproof barrier between mating components (e.g., engine cylinder heads, hydraulic valve covers, or fuel system housings). This function is critical for preventing fluid (oil, coolant, fuel) or gas leakage during heavy-duty operations like construction digging, mining loading, and infrastructure maintenance—directly protecting internal components from contamination, maintaining system pressure stability, and avoiding unplanned downtime caused by leakage-related failures.

Engineered to match original equipment performance standards, it maintains strong sealing performance even under harsh working conditions, including extreme temperatures (-20°C to 180°C), continuous excavator vibration, and exposure to oil or coolant additives. It resists deformation and material degradation, avoiding seal failure that could lead to costly component damage or environmental pollution. Backed by strict performance verification, it guarantees reliable sealing to support uninterrupted operation of ZX350LC-5B/ZX350LCN-5B excavators.

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 31Q7-51120 CYLINDER ASS'Y, RH BOOM SPARKLING MACHINERY

SPARKLING MACHINERY NEW 31Q7-51120 Cylinder Assy, RH Boom is a core hydraulic actuator for Hyundai excavators (construction/mining use). It drives the right-hand boom’s lifting and lowering, ensuring stable force output for heavy-load operations.

Meeting Hyundai OEM standards (31Q7-51120), it resists -30°C to 100°C temps, high hydraulic pressure, and wear, guaranteeing seamless compatibility and long-term reliable boom control performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879