SPARKLING DOOSAN DX190W Parts – Reliable Excavator Components

The K9001469 Bevel Gear is a critical drivetrain component specifically engineered for DOOSAN wheeled excavators including models DX140W, DX170W, DX190W, and SOLAR 185W-V. It is designed to efficiently transmit power between intersecting shafts at precise angles, enabling smooth and reliable torque delivery in the swing or travel reduction gear systems.

Manufactured with premium-grade alloy steel and finished with precision gear-cutting technology, this bevel gear ensures high wear resistance, quiet operation, and extended service life — even in rugged construction environments.

SPARKLING DOOSAN DX190W Parts – Reliable Quality You Can Trust

Since 2013, SPARKLING MACHINERY has dedicated itself to delivering top-quality excavator parts, specializing in DOOSAN DX190W parts that promise durability and precision. Engineered with stability and long-lasting performance in mind, our DOOSAN DX190W parts are crafted through stringent manufacturing processes and rigorous quality control. Whether you need hydraulic components, engine parts, electrical systems, or undercarriage replacements, SPARKLING ensures compatibility and excellence.

Our extensive product range covers essential parts designed to meet the demanding needs of DOOSAN excavators. We offer customized solutions and expert technical support to help you optimize your machinery’s efficiency and lifespan. With a commitment to reducing your operational costs without compromising quality, SPARKLING MACHINERY stands as a reliable partner for professionals worldwide.

Experience peace of mind with parts that maintain your DOOSAN DX190W excavator’s optimal performance in challenging conditions. Our global sales network and customer-focused service emphasize continuous support, innovative solutions, and competitive pricing. Choose SPARKLING for trusted, durable, and high-precision DOOSAN DX190W parts—engineered to power your productivity.

Picture Show

Question you may concern

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

If you have another questions, please feel free to contact us.

K9001469 Bevel Gear for DOOSAN DX140W DX170W DX190W SOLAR 185W-V | Wheel Excavator Transmission Gear Parts

The K9001469 Bevel Gear is a critical drivetrain component specifically engineered for DOOSAN wheeled excavators including models DX140W, DX170W, DX190W, and SOLAR 185W-V. It is designed to efficiently transmit power between intersecting shafts at precise angles, enabling smooth and reliable torque delivery in the swing or travel reduction gear systems.

Manufactured with premium-grade alloy steel and finished with precision gear-cutting technology, this bevel gear ensures high wear resistance, quiet operation, and extended service life — even in rugged construction environments.

EXCAVATOR PARTS MADE IN CHINA NEW 201-45342/201-46298 FUEL PUMP SPARKLING MACHINERY

SPARKLING MACHINERY NEW 201-45342 201-46298 Fuel Pump is a critical engine fuel supply component designed for a wide range of excavator models (widely used in construction, mining, municipal engineering, and large-scale earthmoving projects). As the "engine fuel core", it precisely pressurizes and delivers diesel fuel to the combustion chamber—ensuring stable, consistent fuel flow during high-intensity tasks like heavy digging, rock breaking, and long-hour equipment operation, while optimizing fuel atomization to maintain efficient combustion and avoid engine power loss.

Meeting industry OEM standards (part nos. 201-45342 / 201-46298), it endures -30°C to 120°C working temperatures, resists diesel fuel corrosion and equipment vibration, and guarantees reliable fuel pressure output (rated pressure deviation <0.2 bar). Strict performance testing ensures seamless compatibility with applicable excavator models and long-term stability of the engine fuel system.

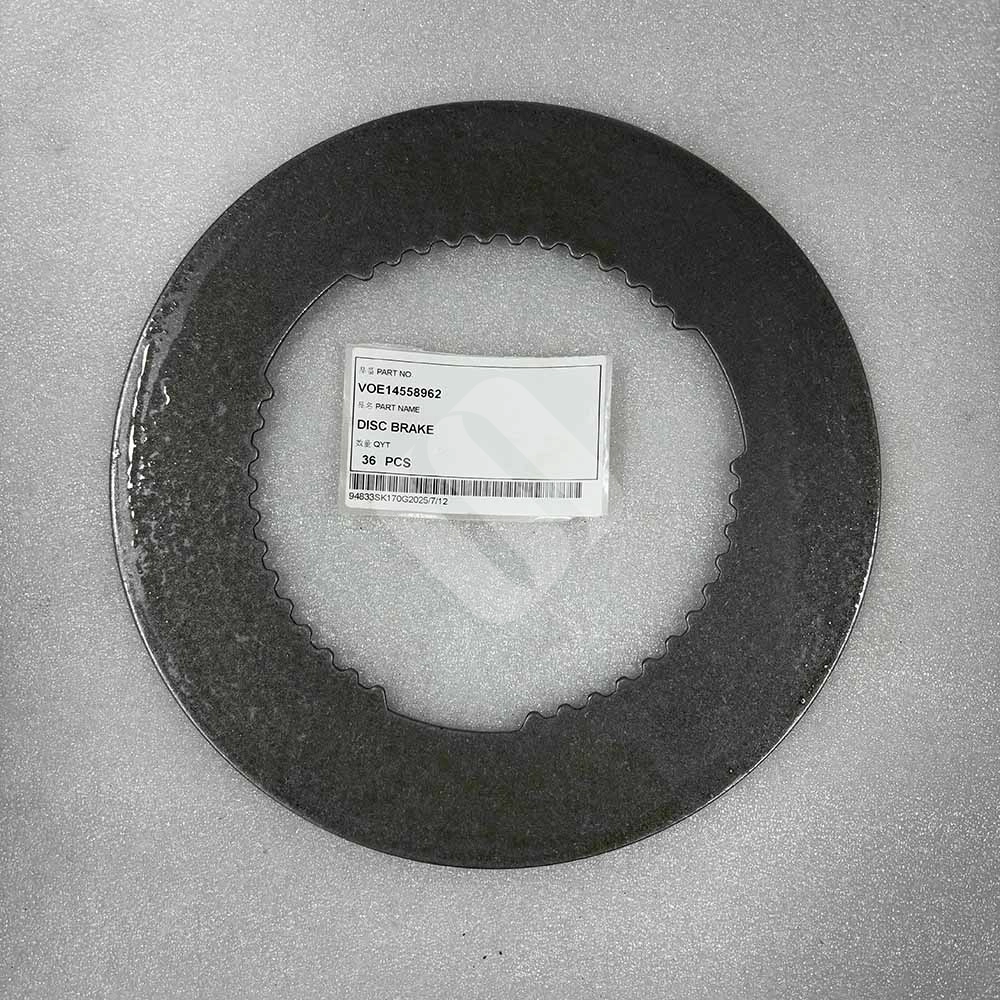

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EW160C EW160D EW160E EW180C EW180D VOE14558962 DISC BRAKE SPARKLING MACHINERY

SPARKLING MACHINERY NEW EW160C EW160D EW160E EW180C EW180D VOE14558962 Disc Brake is a dedicated safety component for VOLVO EW160C/EW160D/EW160E/EW180C/EW180D wheeled excavators (used in road construction, municipal engineering, and material handling). As the core of the braking system, it provides stable stopping force to ensure safe on-road travel and off-road operation, preventing accidents during tasks like loading or navigating uneven terrain.

Meeting VOLVO OEM standards (part no. VOE14558962), it endures high friction, -30°C to 90°C temperatures, and vibration. It resists wear and corrosion, ensuring long-term braking reliability for the five VOLVO models, with strict testing guaranteeing compatibility and safe performance.

HYUNDAI MADE IN CHINA SPARKLING MACHINERY NEW R55W7 R55-7 11M8-42030 RADIATOR

SPARKLING MACHINERY NEW R55W7 R55-7 11M8-42030 Radiator is a dedicated cooling system core component exclusively designed for R55W7 and R55-7 wheel excavators. As the heart of the excavators’ engine cooling system, it efficiently dissipates excess heat generated by the engine during heavy-duty operations—such as urban construction, small-scale digging, and site material handling—by transferring heat from coolant to the surrounding air. This function is critical for maintaining the engine’s optimal operating temperature (82–95°C), preventing overheating that could cause power loss, component warping, or irreversible engine damage.

Engineered to match original equipment performance standards, it maintains high heat dissipation efficiency even under harsh working conditions, including high ambient temperatures (up to 45°C), continuous excavator vibration, and exposure to dust, debris, or rain. It resists coolant leakage and core corrosion, avoiding cooling system failures that lead to unplanned downtime or costly repairs. Backed by strict performance verification, it guarantees reliable heat management to support uninterrupted operation of R55W7/R55-7 wheel excavators.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879