SPARKLING DX225 & DX340LC Excavator Parts – Reliable, High-Quality

Product Summary:SPARKLING offers durable and precise DX225 and DX340LC excavator parts designed for reliable performance. Compatible with top brands and backed by expert support.

SPARKLING DX225 & DX340LC Excavator Parts – Trusted Quality and Performance

Founded in 2013, SPARKLING MACHINERY has established itself as a leading supplier of high-quality excavator parts. Our DX225 and DX340LC parts are engineered to meet the highest standards of stability, precision, and durability, ensuring your equipment runs smoothly in any working condition.

Compatible with major excavator brands such as Caterpillar, Komatsu, Hitachi, and Volvo, our parts cover a comprehensive range of components including hydraulic systems, undercarriage parts, engine components, electrical units, and more. Whether you need replacement parts for maintenance or custom solutions tailored to your specifications, SPARKLING is ready to support your project with expert advice and attentive service.

Each DX225 and DX340LC part undergoes strict quality control to guarantee long-lasting performance. Our commitment to precise manufacturing and rigorous testing means our components withstand harsh environments and heavy workloads. This reliability reduces downtime and lowers maintenance costs, helping you maximize your excavator’s efficiency.

SPARKLING MACHINERY believes in combining innovation with value. We offer competitive pricing without compromising on quality, making our products an excellent choice for contractors and operators worldwide. Backed by a global sales network, professional technical support, and ongoing customer service, SPARKLING is your dependable partner in the excavator parts industry.

Choose SPARKLING DX225 and DX340LC excavator parts for peace of mind that your machinery will perform optimally. With a focus on durability, compatibility, and precision, our products help you keep your operations running smoothly and cost-effectively.

Why Choose SPARKLING DX225 & DX340LC Parts?

- Precision-engineered for durability and stability

- Compatible with leading excavator brands

- Wide product range: hydraulic, engine, electrical, and undercarriage parts

- Strict quality control and testing procedures

- Customized solutions and expert technical support

- Competitive pricing with consistent product quality

- Trusted worldwide since 2013

Experience reliable performance and reduce operational costs with SPARKLING's DX225 and DX340LC excavator parts – built to keep your machinery moving forward.

Picture Show

Frequently Asked Questions

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

If you have any questions about our goods or services, please feel free to contact us.

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EC220D EC235D EC250D EC250E EC300D 14592299 RELIEF VALVE SPARKLING MACHINERY

SPARKLING MACHINERY NEW EC220D EC235D EC250D EC250E EC300D 14592299 Relief Valve is a dedicated hydraulic safety component for VOLVO EC220D/EC235D/EC250D/EC250E/EC300D crawler excavators (heavy-duty equipment for construction/mining). As the hydraulic system’s core safety guard, it precisely limits max pressure to protect pumps, cylinders, and pipelines from overload damage during rock breaking or bulk loading.

Meeting VOLVO OEM standards (part no. 14592299), it endures 34 MPa pressure, -25°C to 105°C temps, and heavy vibration. It resists oil contamination and wear, ensuring long-term reliability for the five VOLVO models, with strict testing guaranteeing compatibility and safe operation.

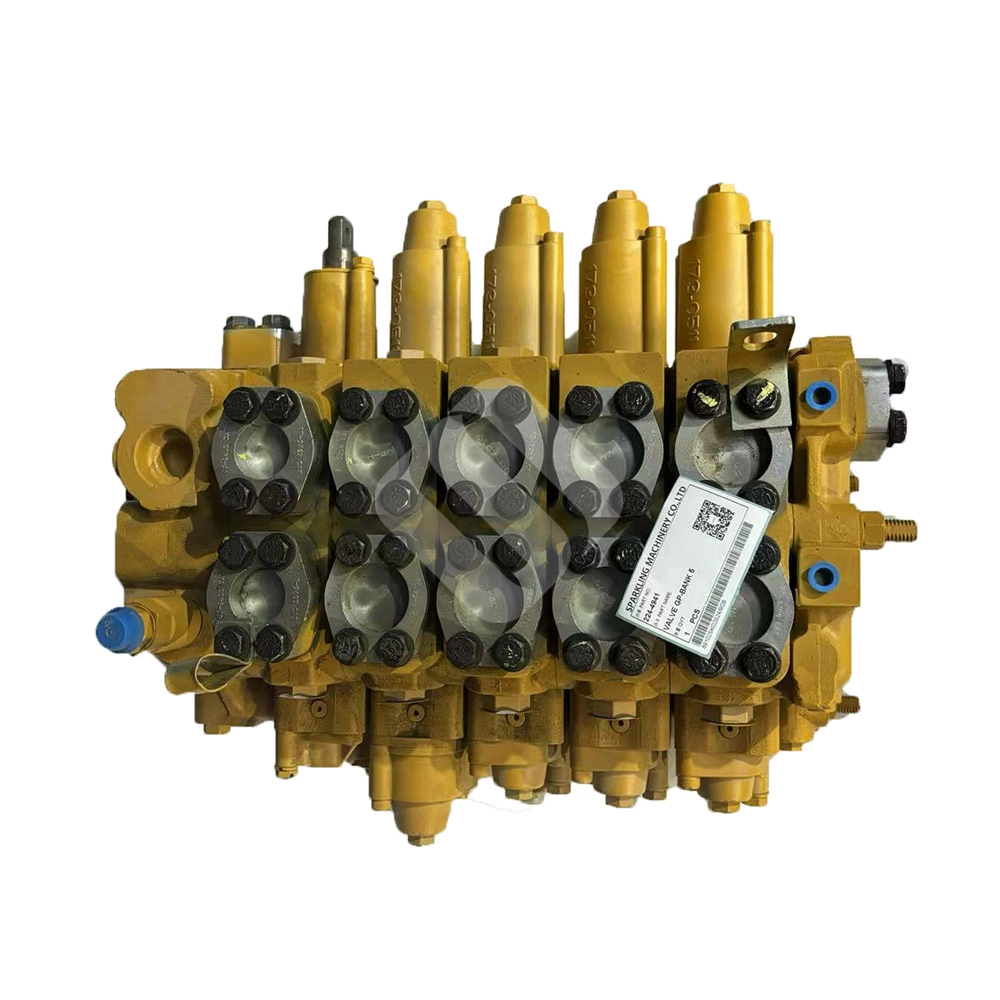

BULLDOZER SPARE PARTS 224-4941 2244941 CA2244941 CONTROL VALVE FOR D7R D7R II D7R XR D7R LGP

Keep your CAT D7R series bulldozers running at peak performance with the CA2244941 Control Valve Assembly, also known by part numbers 224-4941 and 2244941. This essential hydraulic component ensures precise operation of critical functions such as blade lift, tilt, and ripper control.

Key Features:

-

Genuine-fit replacement for CAT D7R / D7R II / D7R XR / D7R LGP

-

Robust construction to withstand high-pressure hydraulic environments

-

Tested and inspected for leakage, performance, and reliability

-

Long service life, minimizing downtime and improving machine productivity

SHANTUI EXCAVATOR PARTS MADE IN CHINA NEW SD16 SD22 SD32 23Y-58D-15000-1 CONTROL PANEL SPARKLING MACHINE

SPARKLING MACHINERY NEW SD16 SD22 SD32 23Y-58D-15000-1 Control Panel is a dedicated integrated control component for Shantui SD16, SD22, and SD32 crawler dozers/excavators (widely used in construction, mining, and land reclamation). As the "central command hub" of the equipment’s cab, it integrates key controls for engine operation, hydraulic functions, and safety systems—enabling operators to monitor real-time data (e.g., speed, temperature) and execute precise commands during heavy tasks like pushing soil, grading terrain, or earthmoving.

Meeting Shantui OEM standards (part no. 23Y-58D-15000-1), it endures -30°C to 85°C temperatures, resists dust and vibration, and maintains stable signal transmission. Strict testing guarantees seamless compatibility with the three Shantui models and long-term reliable cab control.

KHR44570 KHR24470 Converter Compatible with Case CX130C CX160C CX210D Excavators & Sumitomo SH120 A2 730

The KHR44570/KHR24470 converter is a core electrical power regulation component for Case and Sumitomo excavators, ensuring stable DC-DC power conversion.

Key Features

· Stable DC-DC power conversion for reliable electrical supply to excavator systems

· Direct OEM fit for seamless integration with specified Case and Sumitomo models

· Strong anti-interference performance to adapt to complex job site electrical environments

· Wide compatibility covering multiple Case CX-series and Sumitomo SH-series excavators

· Easy installation to reduce equipment downtime during replacement

Compatible Models

· Case Excavators: CX130C, CX160C, CX210D (including variants like CX210D LC, CX210D NLC, CX210D LC LR)

· Sumitomo Excavators: SH120 A2, SH730 (also fits SH120-2, SH75-3B, SH75X-3B, SH125, SH135)

· Interchangeable Part Numbers: KHR44570, KHR24470

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879