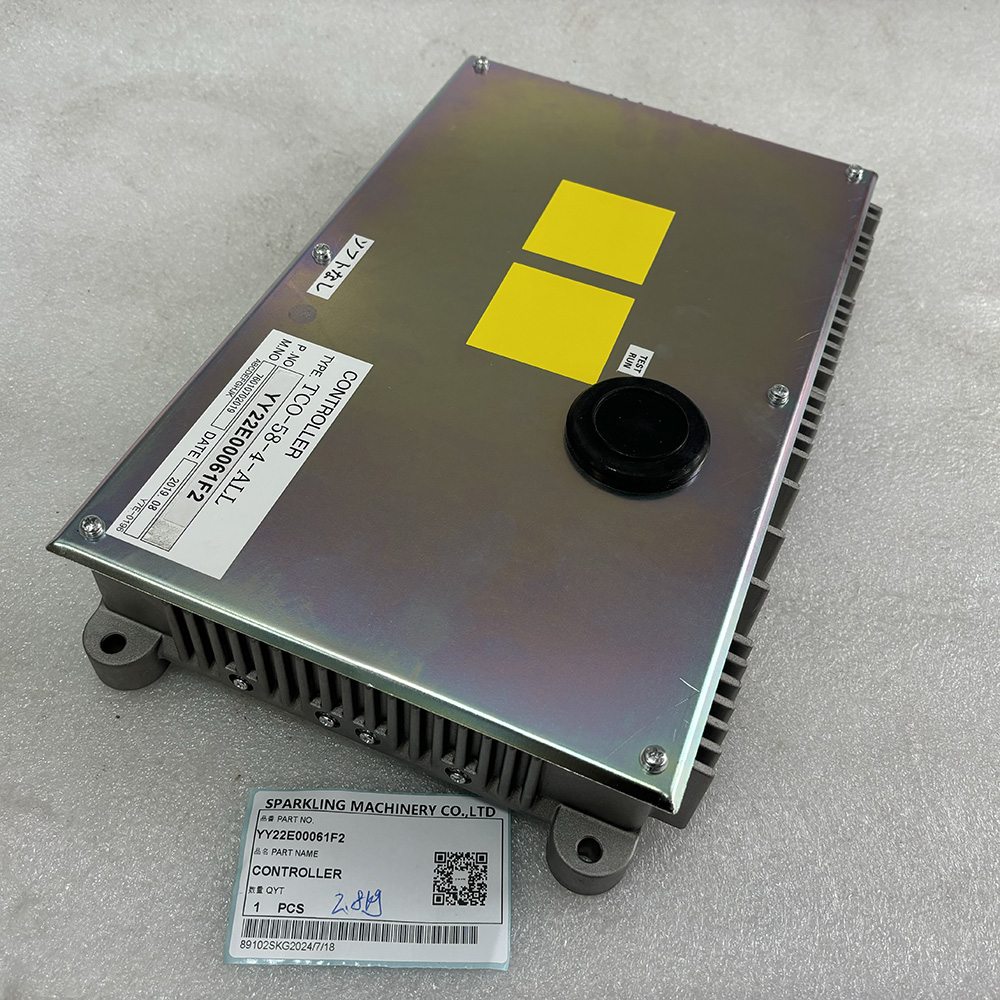

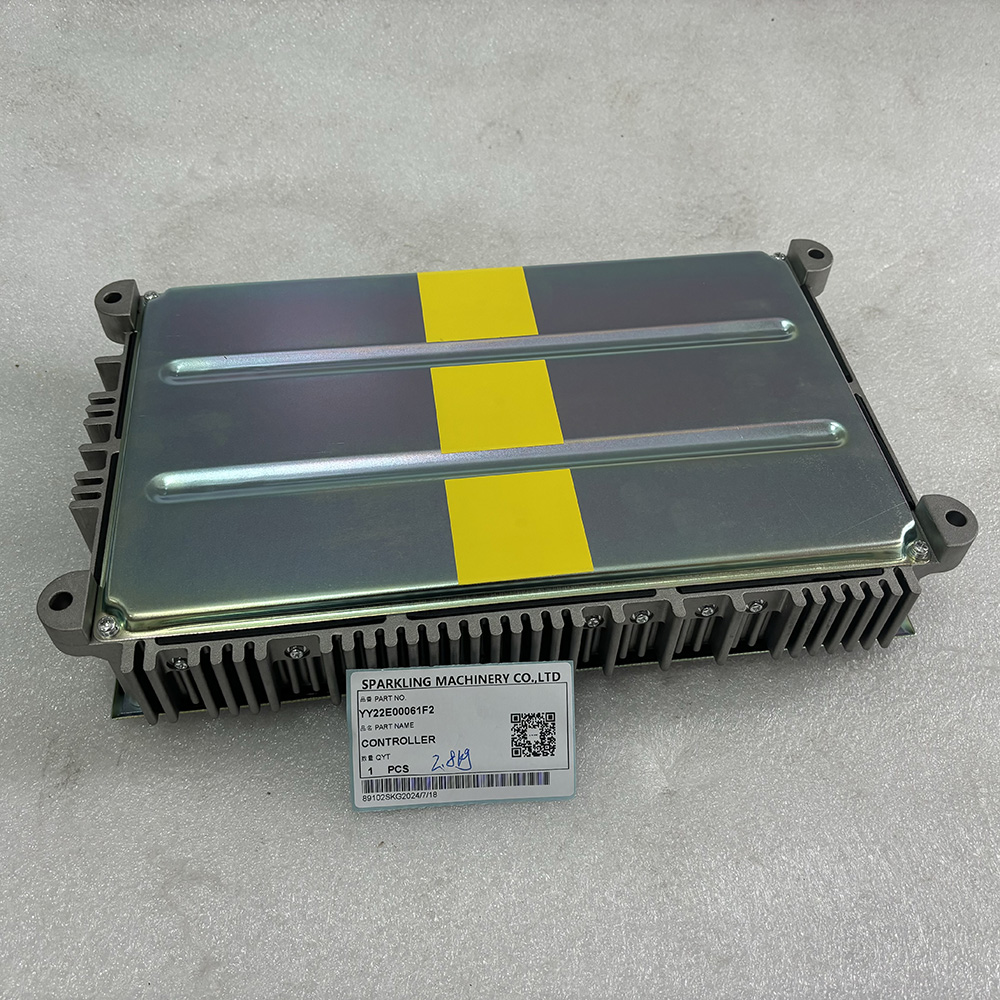

SPARKLING E135SR Control Unit – Reliable Excavator Performance

The YY22E00061F1 / F2 / F5 / F6 Control Unit is an essential electronic component designed for use in New Holland Kobelco E135SRLC and E135SR excavators. This control unit is responsible for managing the excavator’s core electronic systems, including engine, hydraulic functions, and machine diagnostics, ensuring optimal performance and operational efficiency.

This series of controllers is known for its fast data processing, stable communication, and durable circuit design that can withstand the tough environments excavators operate in.

SPARKLING E135SR Control Unit – Precision and Reliability You Can Trust

The SPARKLING E135SR control unit is engineered to meet the highest standards for excavator performance and durability. As a vital component in excavator operation, this control unit ensures smooth, precise control of the machine’s functions, enhancing productivity and operational safety. Perfectly compatible with various brands, including Caterpillar, Komatsu, Hitachi, and Volvo, the E135SR control unit delivers consistent performance under demanding conditions.

SPARKLING MACHINERY, established in 2013, specializes in manufacturing High Quality excavator parts with a strong focus on stability, precision, and enduring quality. Our commitment to strict production standards and quality control guarantees the E135SR control unit’s exceptional reliability and longevity. Designed with advanced technology and robust materials, it withstands harsh environments while maintaining optimal functionality.

Customers benefit from SPARKLING’s comprehensive service, including customized solutions, expert technical support, and ongoing maintenance advice, ensuring maximum uptime and cost-efficiency. Our global sales network and competitive pricing make the E135SR control unit an accessible, smart investment for operators looking to upgrade or replace excavator components without sacrificing quality.

Choose SPARKLING’s E135SR control unit for superior control, trusted durability, and precise performance. Experience peace of mind with a product backed by innovation, expertise, and commitment to excellence—helping you keep your excavator running at its best.

Product Images

Question you may concern

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

If you have any questions about our goods or services, please feel free to contact us.

E135SRLC E135SR Control Unit YY22E00061F1 F2 F5 F6 | Excavator ECU ECM Module | SPARKLING MACHINERY

The YY22E00061F1 / F2 / F5 / F6 Control Unit is an essential electronic component designed for use in New Holland Kobelco E135SRLC and E135SR excavators. This control unit is responsible for managing the excavator’s core electronic systems, including engine, hydraulic functions, and machine diagnostics, ensuring optimal performance and operational efficiency.

This series of controllers is known for its fast data processing, stable communication, and durable circuit design that can withstand the tough environments excavators operate in.

376-9483 Control GP Handle for Caterpillar Excavators & Wheel Loaders | Fits CAT 312D2, 312D, 320D, 950K, 962K, 966K

· Function: This is an ergonomic joystick handle used to control secondary machine functions, such as auxiliary hydraulics, attachment movements (e.g., thumb or grapple), and transmission shifting.

· Design: It typically features multiple integrated thumb buttons and/or rocker switches to allow for multi-function operation without the operator releasing the joystick.

· Durability: Built to withstand heavy vibration, dust, and moisture common in construction and mining environments.

Compatible Equipment - The 376-9483 assembly is found across several Caterpillar product lines:

· Excavators: 312D2, 320D2, 323D2, 329D2, 330D2, 336D2, 349D2.

· Wheel Loaders: 950K, 962K, 966K, 972K, 980K.

· Motor Graders: 12M, 14M, 16M, 120M, 140M, 160M.

Other Specialized Equipment

· Pipelayers: PL61.

· Material Handlers: M318D MH, M322D MH, MH3049, MH3059.

VOLVO MADE IN CHINA SPARKLING MACHINERY NEW EC160C EC180C EC210C EC235C EC240B EC240C EC250D VOE14531612 FAN MOTOR

SPARKLING MACHINERY NEW VOE14531612 Fan Motor is a critical cooling system component designed for compatible construction machinery, such as excavators and loaders. As the "power source" of the machinery’s cooling fan, it drives the fan to generate consistent airflow, which dissipates heat from key systems including the engine radiator, hydraulic oil cooler, and intercooler. This function is essential for preventing overheating—especially during heavy-duty operations like prolonged digging, high-load lifting, and continuous idling in construction, mining, or infrastructure projects—ensuring the machinery maintains optimal operating temperatures and stable performance.

Engineered to match original equipment performance standards, it maintains reliable rotational speed and torque output even under harsh working conditions, such as high ambient temperatures, intense vibration, and dust or moisture exposure. It prevents fan stalling or speed fluctuations, avoids cooling inefficiencies that lead to system damage, and supports uninterrupted machinery operation. Backed by strict performance verification, it guarantees long-term reliability for the cooling system.

Construction Spare Parts 4307226 Relief Valve For Cummins Engine Isx15 Cm2350 x101, Qsx15 Cm2350 x105

- Manufacturer: Cummins.

- Function: Safeguards the engine by precisely regulating pressure within the fuel, lubrication, and cooling systems. It automatically releases excess fluid when the pressure exceeds a set threshold.

- Compatible Engines: The 0.3KG valve is compatible with several Cummins engine models, including the ISX15 CM2350 X101, QSX15 CM2350 X105, X15 CM2350 X116B, X15 CM2350 X123B, and X15 CM2450 X134B.

- Construction: Features a robust design crafted from high-quality, durable materials to withstand demanding conditions.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879