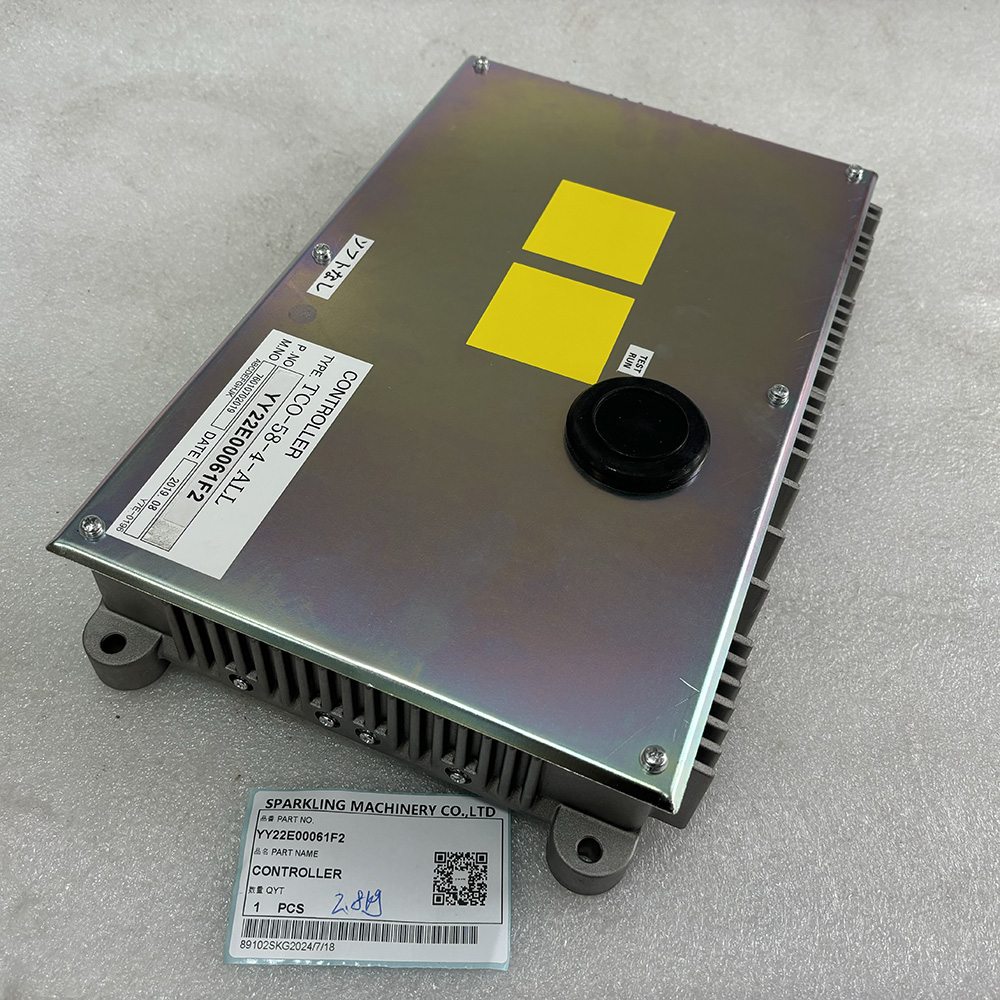

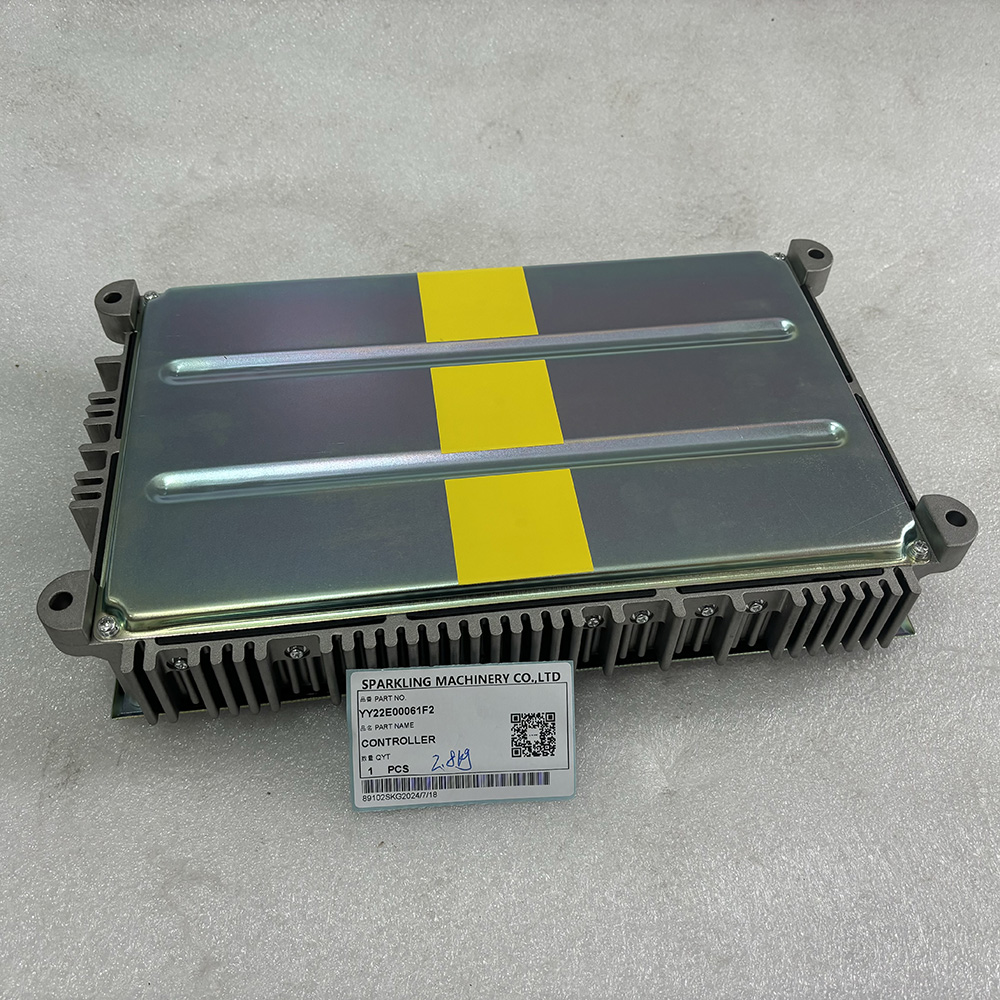

SPARKLING E135SRLC ECM – Reliable Excavator Engine Control Module

The YY22E00061F1 / F2 / F5 / F6 Control Unit is an essential electronic component designed for use in New Holland Kobelco E135SRLC and E135SR excavators. This control unit is responsible for managing the excavator’s core electronic systems, including engine, hydraulic functions, and machine diagnostics, ensuring optimal performance and operational efficiency.

This series of controllers is known for its fast data processing, stable communication, and durable circuit design that can withstand the tough environments excavators operate in.

SPARKLING E135SRLC ECM: Precision, Reliability, and Performance You Can Trust

SPARKLING MACHINERY, a leader in high-quality excavator parts since 2013, proudly presents the E135SRLC ECM—a cutting-edge Engine Control Module designed to optimize your excavator’s performance with unmatched stability and precision. Engineered to meet the rigorous demands of top excavator brands such as Caterpillar, Komatsu, Hitachi, and Volvo, the E135SRLC ECM seamlessly integrates into your machinery ensuring smooth and efficient engine management.

With a dedicated focus on endurance and reliability, the SPARKLING E135SRLC ECM undergoes meticulous manufacturing and rigorous quality control processes. This ensures optimal performance under a variety of operating conditions, reducing downtime and enhancing productivity. Our commitment to innovation and precision means this ECM not only improves engine efficiency but also helps reduce fuel consumption and emissions, contributing to more sustainable operations.

SPARKLING MACHINERY offers tailored solutions and expert technical support for the E135SRLC ECM, ensuring each installation is optimized for your specific excavator model and working environment. Our worldwide sales and service network guarantees timely delivery and ongoing professional consultation, providing peace of mind every step of the way.

Choose SPARKLING E135SRLC ECM to experience superior control, consistent reliability, and cost-effective maintenance. Trust in our expertise and dedication to quality—your excavator deserves nothing less.

Detailed display

FAQ

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

If you have any other questions, please write email to us or call us , we will reply you as soon as possible.

E135SRLC E135SR Control Unit YY22E00061F1 F2 F5 F6 | Excavator ECU ECM Module | SPARKLING MACHINERY

The YY22E00061F1 / F2 / F5 / F6 Control Unit is an essential electronic component designed for use in New Holland Kobelco E135SRLC and E135SR excavators. This control unit is responsible for managing the excavator’s core electronic systems, including engine, hydraulic functions, and machine diagnostics, ensuring optimal performance and operational efficiency.

This series of controllers is known for its fast data processing, stable communication, and durable circuit design that can withstand the tough environments excavators operate in.

Komatsu EXCAVATOR PARTS MADE IN CHINA NEW HB205 HB215 PC200 PC200LL PC210 PC220 708-2L-07710 VALVE ASSY SPARKLING MACHINERY

SPARKLING MACHINERY NEW HB205 HB215 PC200 PC200LL PC210 PC220 708-2L-07710 Valve Assy is a dedicated hydraulic control assembly for Komatsu HB205, HB215, PC200, PC200LL, PC210, and PC220 crawler excavators (widely used in construction, mining, and infrastructure projects). As the "hydraulic control hub", it integrates multiple valves to regulate oil flow, pressure, and direction—powering key functions like boom lifting, bucket digging, and swing movements, ensuring smooth, precise operation during high-intensity tasks while maintaining system stability.

Meeting Komatsu OEM standards (part no. 708-2L-07710), it endures 30 MPa working pressure, -30°C to 95°C temperatures, resists hydraulic oil corrosion and vibration, and ensures leak-free performance. Strict testing guarantees seamless compatibility with the six Komatsu models and long-term hydraulic system reliability.

HIGH-QUALITY 270-6217 GEAR IDLER for Caterpillar Construction Equipment 303.5C, 303.5D, 303C CR, 304C CR, 304D CR Mini Hydraulic Excavators

The HIGH-QUALITY 270-6217 GEAR IDLER is a premium power transmission component meticulously engineered for Caterpillar Construction Equipment, specifically tailored to meet the precision alignment and durability demands of 303.5C, 303.5D, 303C CR, 304C CR, and 304D CR Mini Hydraulic Excavators. As a critical part of the machinery’s drive system, this gear idler maintains optimal tension and alignment of drive gears or chains, ensuring smooth power distribution, reducing mechanical wear, and preventing component misalignment during compact-scale construction tasks.

Designed to seamlessly integrate with Caterpillar’s mini excavator architecture, it delivers consistent performance that enhances machinery operational efficiency, extends drive system service life, and ensures reliable performance in tight or demanding workspaces.

Key Features

· Custom-engineered for perfect compatibility with Caterpillar 303.5C, 303.5D, 303C CR, 304C CR, 304D CR Mini Hydraulic Excavators

· Precision-machined tooth profile and outer diameter for seamless meshing and consistent tension control

· Enhanced structural rigidity to withstand continuous mechanical stress and prevent deformation

· Superior wear resistance for long-term reliability in frequent-use, high-cycle operation

· Strict adherence to Caterpillar OEM specifications for seamless integration and consistent drive system performance

Compatible Models

· Caterpillar Construction Equipment Mini Hydraulic Excavators: 303.5C, 303.5D, 303C CR, 304C CR, 304D CR

Caterpillar EXCAVATOR PARTS MADE IN CHINA NEW 312D2 312E 313D2 360-3986 CONNECTING ROD BEARING SPARKLING MACHINERY

SPARKLING MACHINERY NEW 312D2 312E 313D2 360-3986 Connecting Rod Bearing is a critical engine lubrication and load-bearing component for Caterpillar 312D2, 312E, and 313D2 excavators (widely used in construction, municipal engineering, and medium-scale mining). As the "engine motion buffer", it reduces friction between the connecting rod and crankshaft, while absorbing impact loads from piston reciprocation—ensuring smooth power transmission during tasks like digging, lifting, and material handling, and protecting the engine’s core moving parts from wear.

Meeting Caterpillar OEM standards (part no. 360-3986), it endures -30°C to 150°C engine temperatures, resists oil oxidation and metal fatigue, and maintains stable lubrication performance. Strict testing guarantees seamless compatibility with the three Caterpillar models and long-term engine operational reliability.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879