SPARKLING EC140D Switch - Reliable Excavator Electrical Component

The Volvo Switch (VOE 14643925) is a high-quality electrical switch designed for Volvo excavators including models EC120D, EC140D/E, EC160E, EC170D, EC180E, EC200D, EC210D, EC220D/E, EC250D/E, EC300D/E, EC350D/E, EC380D/E, EC480D/E and more amazon.co.uk+15avspare.com+15zzyexcavatorparts.com+15. This durable push-button or console-mounted switch ensures reliable operation of working hydraulic or accessory systems such as hammer/shear pedals. Manufactured to OE specifications, it guarantees a precise fit, consistent performance, and comes with a workmanship warranty—ideal for both genuine and aftermarket applications.

SPARKLING EC140D Switch – Precision and Reliability You Can Trust

The SPARKLING EC140D switch is engineered to meet the highest standards of performance and durability, designed specifically for excavators requiring dependable electrical components. Since 2013, SPARKLING MACHINERY has built a reputation for delivering High Quality excavator parts focused on stability, precision, and perseverance. Our EC140D switch exemplifies these values, ensuring seamless control and long-lasting operation in demanding working environments.

Manufactured with strict quality control processes, the EC140D switch guarantees compatibility with leading excavator brands such as Caterpillar, Komatsu, Hitachi, and Volvo. This attention to detail makes it the ideal choice for maintaining optimal machine performance and reducing downtime. Whether used in standard or heavy-duty applications, the EC140D switch delivers reliable electrical function, minimizing risks of malfunctions and breakdowns.

SPARKLING MACHINERY offers not only high-quality parts but also customized solutions tailored to your specific operational needs. Our experienced technical support team provides meticulous consultation to help you select the best product and troubleshoot any challenges. With a comprehensive warranty and worldwide after-sales service, customers can have peace of mind when choosing the SPARKLING EC140D switch.

Committed to innovation and customer satisfaction, SPARKLING MACHINERY continuously strives to improve product quality while offering competitive pricing and cost-effective solutions. Trust in our EC140D switch to enhance your excavator’s efficiency and durability, backed by a global network known for excellence and reliability.

Picture Show

Frequently Asked Questions

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

About other questions pls contact me directily.

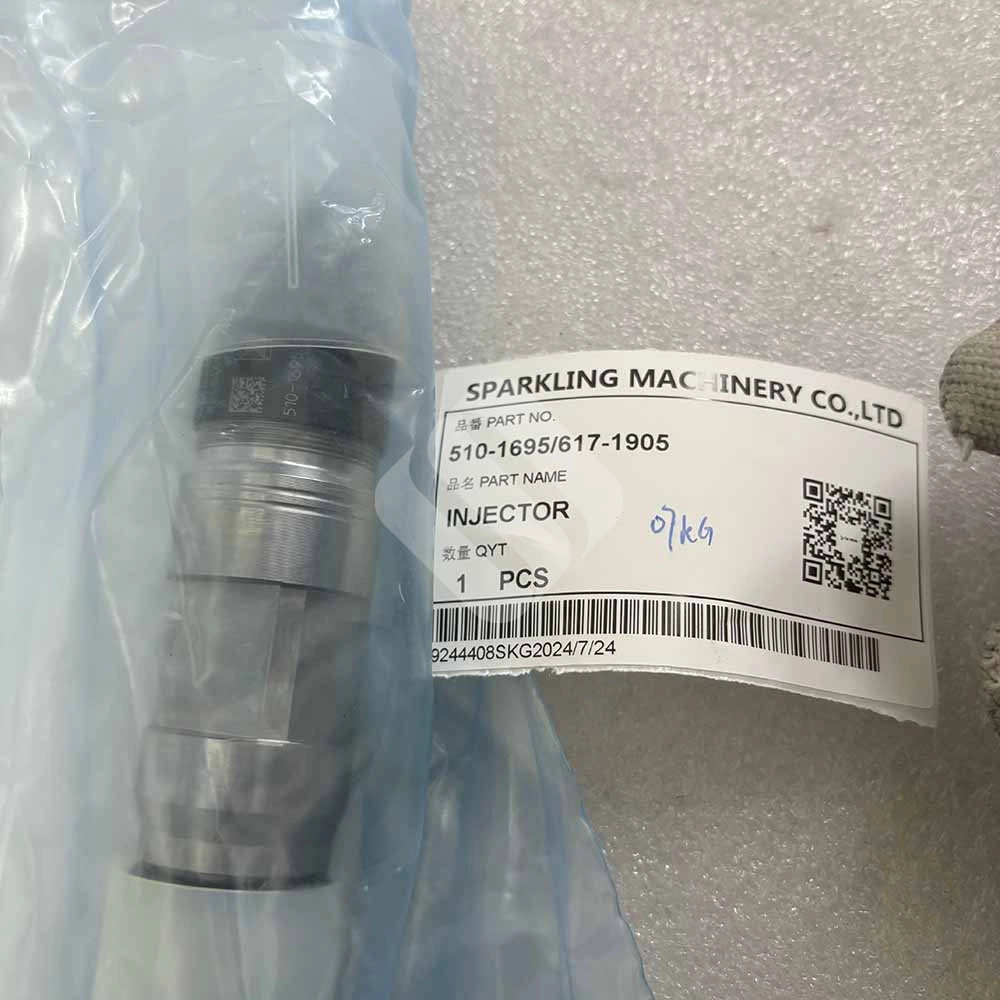

Caterpillar EXCAVATOR PARTS MADE IN CHINA NEW 336GC 340GC 345GC 350GC 510-1695/617-1905 INJECTOR SPARKLING MACHINERY

SPARKLING MACHINERY NEW 336GC 340GC 345GC 350GC 510-1695/617-1905 Injector is a core engine fuel injection component for Caterpillar 336GC, 340GC, 345GC, and 350GC excavators (widely used in heavy construction, mining, and large-scale infrastructure projects). As the "fuel atomization core", it precisely sprays fuel into the combustion chamber—ensuring efficient fuel combustion during high-intensity tasks like rock breaking, deep digging, and heavy lifting, while maintaining stable engine power output and reducing fuel waste.

Meeting Caterpillar OEM standards (part nos. 510-1695/617-1905), it endures -30°C to 200°C engine temperatures, resists fuel corrosion and vibration, and guarantees consistent injection pressure. Strict testing ensures seamless compatibility with the four Caterpillar models and long-term engine reliability.

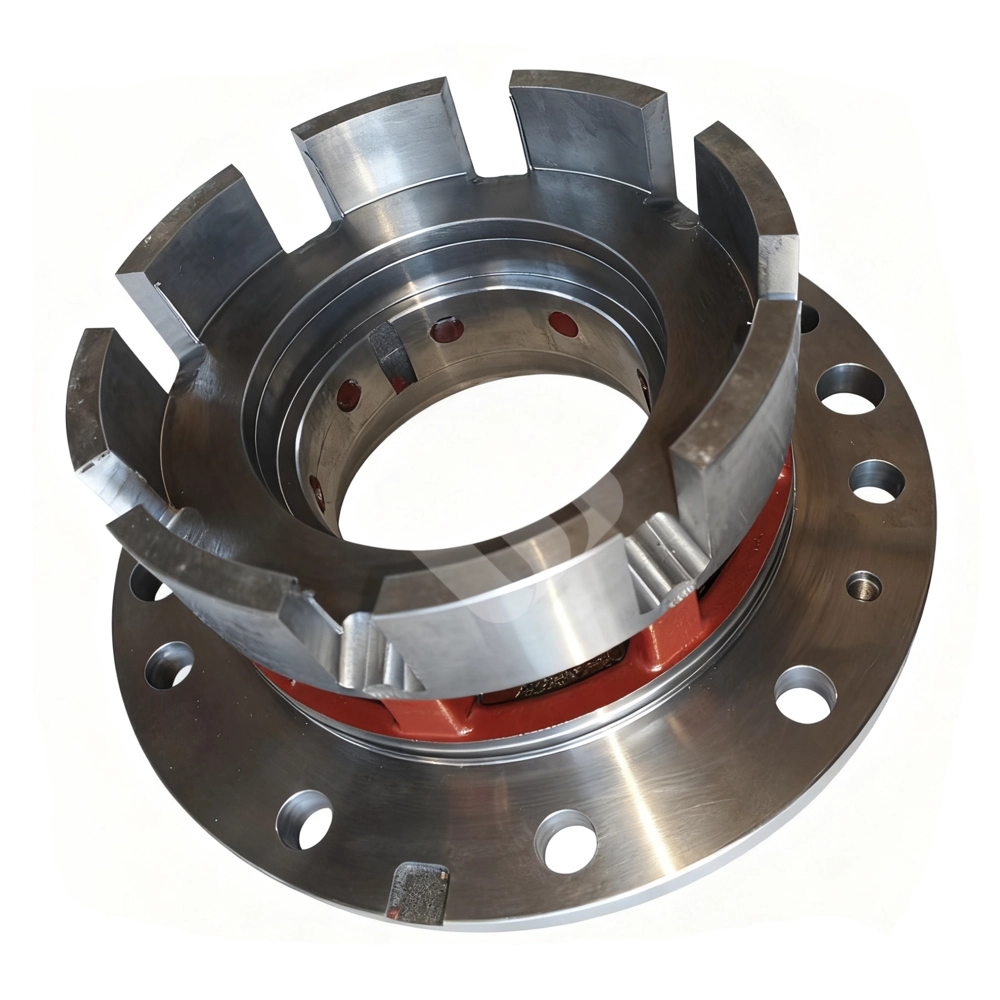

Hub-Axle ZGAQ-03591 For Hyundai Wheel Excavator R160W-9A R170W-7 R170W-7A R170W-9

Part number ZGAQ-03591 refers to a Hub-Axle (also known as a front or rear axle hub) used in Hyundai wheeled excavators.

Part Name: Hub-Axle / HUB, FR AXLE / Axle Hub.

Function: A structural component of the excavator's axle that the wheel mounts onto, crucial for the vehicle's mobility.

Weight: Approximately 34 kg (75 lbs).

Compatibility: Designed specifically for Hyundai R-series wheeled excavators.

The ZGAQ-03591 axle hub is used on various Hyundai wheeled excavator models, typically within the 7-Series and 9-Series ranges:

R160W-9A

R170W-7 and R170W-7A

R170W-9 and R170W-9S

R180W-9A and R180W-9S

R210W-9

Doosan HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW DX340LC 404-00094A GEAR, SWING REDUCTION SPARKLING MACHINERY

SPARKLING MACHINERY NEW DX340LC 404-00094A Swing Reduction Gear is a core transmission component exclusively for Doosan DX340LC excavators (heavy-duty construction/mining use). It reduces engine speed to deliver high torque for smooth, precise upper-structure rotation.

Meeting Doosan OEM standards (404-00094A), it resists -30°C to 100°C temps, wear, and impact, ensuring seamless compatibility and long-term reliable swing performance.

Hyundai MADE IN CHINA SPARKLING MACHINERY NEW R170W7 R170W7A R170W9S ZGAQ-02283 CYLINDER-STEERING

SPARKLING MACHINERY NEW R170W7 R170W7A R170W9S ZGAQ-02283 Cylinder-Steering is a premium China-made hydraulic component specifically engineered for R170W7, R170W7A, and R170W9S wheel excavators. As a critical part of the steering system, it converts hydraulic pressure into linear motion to enable smooth and precise directional control, ensuring stable maneuvering during operation, positioning, and job site navigation.

Designed to original equipment standards, it maintains consistent force output and responsive operation even under heavy loads and continuous use. With optimized seal design for leak resistance and robust structural integrity, it adapts seamlessly to harsh working environments, from muddy construction sites to rough terrain. Backed by strict quality verification, it guarantees reliable performance to support safe and uninterrupted machinery operation.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879