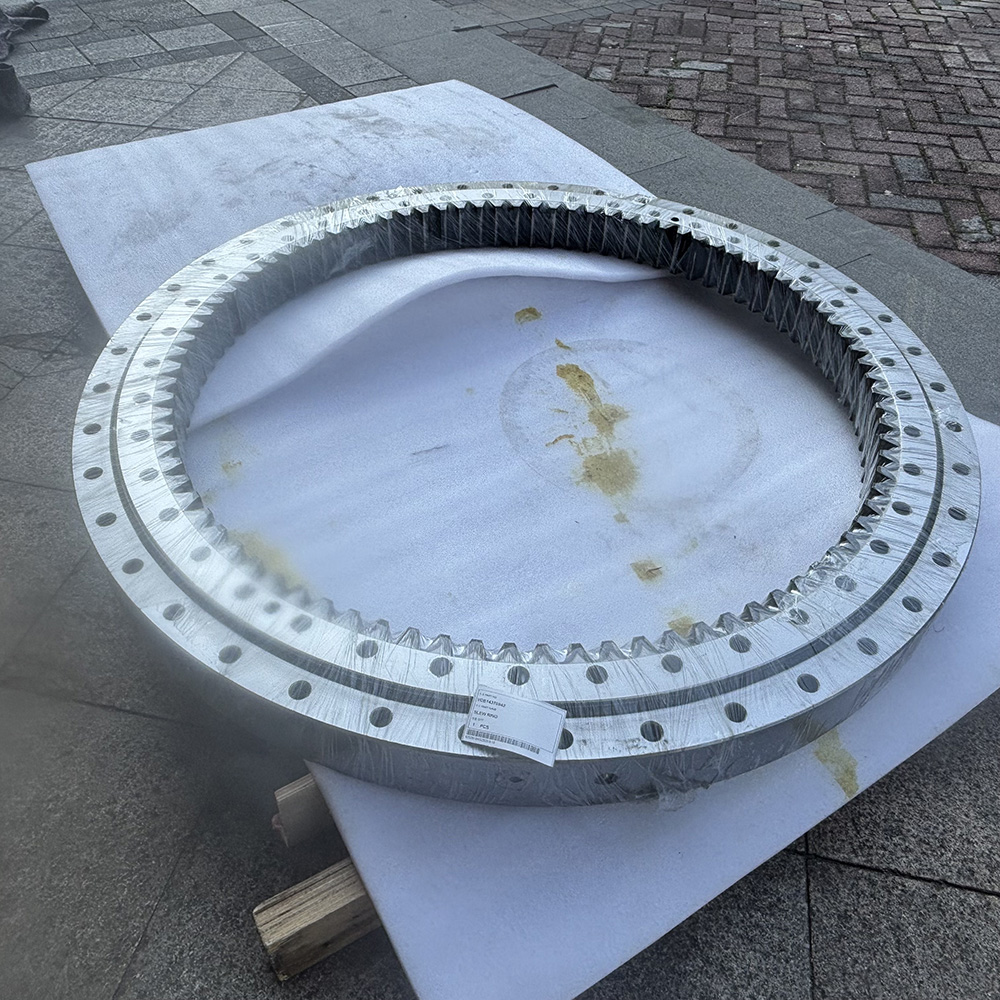

SPARKLING EW160B Excavator Slew Ring – Durable & Precise

slewing ring 14370942:

Outer diameter: 1116 mm

Inner diameter: 883 mm

Number of teeth: 90

Teeth: internal teeth

Number of holes on outer ring: 42 x Ø18 equal spacing

Number of holes on inner ring: 42 x Ø18 equal spacing

Height of outer ring: 83 mm

Height of inner ring: 76 mm

Total height: 92 mm

Height of teeth: 62 mm

Weight: 184 kg

Introducing the SPARKLING EW160B Excavator Slew Ring – engineered for superior durability and precision. As a core component of your excavator’s rotational system, the EW160B slew ring from SPARKLING ensures smooth, reliable operation, even under the most demanding working conditions. Designed with meticulous craftsmanship and advanced manufacturing techniques, this slew ring delivers enhanced stability and longevity, minimizing downtime and maximizing productivity.

At SPARKLING MACHINERY, founded in 2013, we specialize in high-quality excavator parts compatible with major brands like Caterpillar, Komatsu, Hitachi, and Volvo. Our commitment to stability, precision, and perseverance shines through every EW160B excavator slew ring we produce. Rigorous quality control guarantees that our slew rings withstand harsh environments while maintaining optimal performance.

Understanding your needs, SPARKLING offers not just parts but complete customer care: from personalized consultations to tailored solutions and ongoing technical support. We value your investment and work tirelessly to provide competitive pricing without sacrificing quality, helping you reduce operational costs while enhancing machine efficiency.

Choose the SPARKLING EW160B excavator slew ring for a trusted, long-lasting solution that supports your excavator’s core functions. Backed by our global sales network and driven by innovation, SPARKLING MACHINERY is your reliable partner for excavator excellence.

Product Image

Q&A

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

EC160 EW160 EW160B VOE 14370942 VOE14370942 14370942 SLEW RING 184KG

slewing ring 14370942:

Outer diameter: 1116 mm

Inner diameter: 883 mm

Number of teeth: 90

Teeth: internal teeth

Number of holes on outer ring: 42 x Ø18 equal spacing

Number of holes on inner ring: 42 x Ø18 equal spacing

Height of outer ring: 83 mm

Height of inner ring: 76 mm

Total height: 92 mm

Height of teeth: 62 mm

Weight: 184 kg

DISC FRICTION For 0501-213-016 0501213016 DOOSAN DX200 ZGAQ-02025 K9001585

Ensure superior braking and power transmission with the SPARKLING MACHINERY high-performance Friction Disc (Part No. ZGAQ-02025 / K9001585). Specifically designed for Doosan DX200 excavators and ZF axle assemblies (often associated with system seal 0501-213-016), these discs are built to provide consistent friction coefficients and exceptional heat dissipation. In future, upgrade your fleet with SPARKLING MACHINERY's wear-resistant technology to maximize uptime in the most demanding environments.

Key Features from SPARKLING MACHINERY:

Exact OEM Fitment: Fully compatible with Doosan part number K9001585 and Hyundai/ZF part number ZGAQ-02025.

Premium Friction Material: Engineered with advanced composite materials to resist glazing and ensure smooth operation under heavy loads.

Enhanced Durability: Specifically heat-treated to withstand the high-torque requirements of the Doosan DX200 series.

System Synergy: Perfectly matched for use alongside ZF components like the 0501213016 seal for a complete axle overhaul.

Compatible Equipment:

Doosan Excavator: DX200, DX210, and related wheel/crawler models.

Systems: ZF Axles and Transmission assemblies.

250V 13A DRC16-24SA Connector - Construction Machinery Spare Parts

The 250V 13A DRC16-24SA connector is a high-reliability electrical connection component for construction machinery, ensuring stable power and signal transmission. As an OEM-compatible spare part, it meets heavy-duty job site demands, supports equipment electrical system efficiency, and prevents connection failures.

Key Features

· 250V/13A rated specifications for safe and stable electrical transmission

· Secure connection design to resist vibration and harsh environmental impacts

· Direct OEM-compatible fit for seamless integration with machinery electrical systems

· Wide applicability across various construction machinery models

· Easy plug-and-play installation to reduce downtime

Compatible Models

· Construction Machinery: Suitable for a wide range of construction equipment requiring 250V 13A DRC16-24SA specification connectors (including excavators, loaders, rollers, and other heavy machinery)

· Interchangeable Part Numbers: DRC16-24SA

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EC160B EC180B EW160B 14589157 SEAL KIT SPARKLING MACHINERY

SPARKLING MACHINERY NEW EC160B EC180B EW160B 14589157 Seal Kit is a dedicated, all-in-one sealing solution exclusively designed for VOLVO EC160B, EC180B excavators, and EW160B wheeled excavators—versatile equipment widely used in construction, municipal maintenance, and light mining projects. As a core protective component for the machinery’s hydraulic systems, it covers critical areas including hydraulic cylinder rods, valve connections, and pump interfaces, forming reliable leakproof barriers. This function is essential for maintaining stable hydraulic pressure, ensuring smooth and responsive operation of core mechanisms (boom lifting, arm digging, bucket tilting), and preventing dust, debris, or moisture from contaminating internal hydraulic parts. It directly reduces the risk of hydraulic system failures, avoids unplanned downtime, and eliminates costly repairs caused by oil leaks during tasks like trench digging, material loading, and road maintenance.

Engineered to meet VOLVO’s original equipment standards, the seal kit maintains consistent sealing reliability even under harsh conditions: high hydraulic pressure (up to 35 MPa), extreme temperature fluctuations (-25°C to 105°C), and continuous machinery vibration. It resists oil aging and wear, providing long-lasting protection for the hydraulic systems of EC160B/EC180B/EW160B models. Backed by strict performance verification, it guarantees uninterrupted sealing support for these VOLVO machines.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879