SPARKLING Excavator Cooling Parts – Precision & Reliability

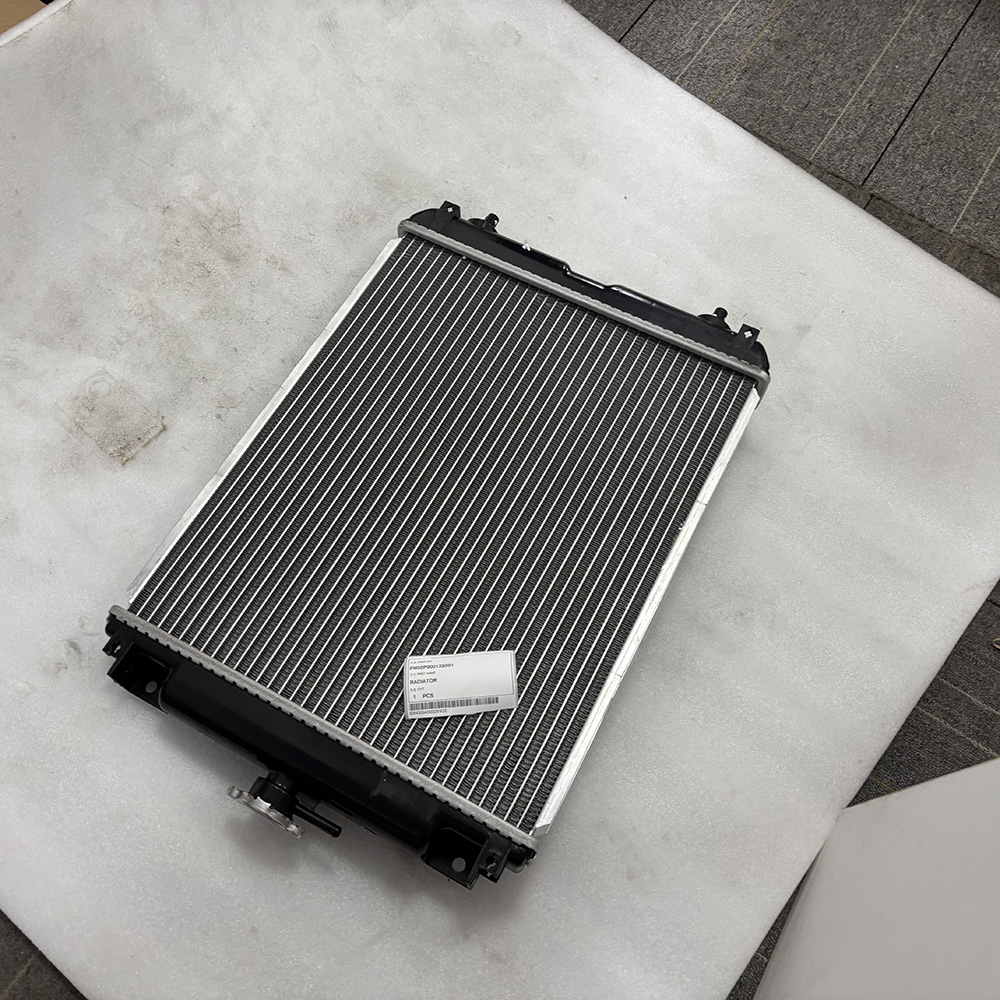

The PM05P00013S001 Radiator, offered by SPARKLING MACHINERY, is a high-quality replacement cooling system component specifically designed for New Holland E27B/E27BSR, CASE CX27B, and Kobelco SK27SR-3 mini excavators.

Built using premium aluminum and designed for efficient heat dissipation, this radiator ensures optimal engine performance and longevity even in demanding work environments. It matches OEM specifications and comes ready to install—making it an ideal choice for maintenance, replacement, or refurbishment.

SPARKLING Excavator Cooling Parts – Reliable Performance You Can Trust

Since 2013, SPARKLING MACHINERY has been a trusted name in the excavator parts industry, specializing in high-quality excavator cooling parts. Designed to meet the rigorous demands of heavy machinery, our cooling components ensure optimal engine temperature management, enhancing the durability and performance of your excavator.

Our excavator cooling parts are engineered with precision and manufactured under strict quality controls, guaranteeing stability and reliability even in challenging working conditions. Compatible with major brands such as Caterpillar, Komatsu, Hitachi, and Volvo, SPARKLING’s cooling parts maintain your equipment’s efficiency and reduce the risk of costly downtime.

At SPARKLING MACHINERY, we understand the critical role cooling systems play in prolonging engine life and maximizing productivity. That’s why we offer tailored solutions, backed by expert technical support and thorough consultation. Our commitment to innovation, altruism, and perseverance drives us to provide superior products at competitive prices—helping you minimize costs without compromising on quality.

With a comprehensive global sales network, SPARKLING is your dependable partner for excavator cooling parts. Trust in our experience and dedication to keep your equipment running smoothly and confidently.

Picture Show

Q&A

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

If you have any questions or concern, please contact us.

SPARKLING MACHINERY E27B E27BSR CX27B SK27SR-3 PM05P00013S001 RADIATOR

The PM05P00013S001 Radiator, offered by SPARKLING MACHINERY, is a high-quality replacement cooling system component specifically designed for New Holland E27B/E27BSR, CASE CX27B, and Kobelco SK27SR-3 mini excavators.

Built using premium aluminum and designed for efficient heat dissipation, this radiator ensures optimal engine performance and longevity even in demanding work environments. It matches OEM specifications and comes ready to install—making it an ideal choice for maintenance, replacement, or refurbishment.

Hitachi HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW ZH200-A ZH200LC-A ZW250-5B ZX200-5G ZX200LC-5G ZX210H-5G XB00001051 CORE SPARKLING MACHINERY

SPARKLING MACHINERY NEW XB00001051 Core is a core functional component for Hitachi ZH200-A/ZH200LC-A/ZW250-5B/ZX200-5G/ZX200LC-5G/ZX210H-5G excavators (construction/mining use). It supports critical system operations (hydraulic/thermal management) with stable performance, meeting Hitachi OEM standards (XB00001051). Resistant to -30°C to 120°C temps, corrosion, and heavy-duty operational stress, it ensures seamless compatibility and reliable long-term functionality for demanding workflows.

This part is a primary replacement for medium to large Hitachi crawler excavators, specifically those in the -5 and -5G generations:

Hitachi ZAXIS-5 Series: ZX200-5G, ZX210H-5G, ZX240-5G, ZX250H-5G, ZX330-5G, ZX350H-5G, ZX360-5, and ZX470-5G.

Other Models: ZX280-5G, ZX290LC-5B, ZX490, ZX520, ZX670, and ZX870

Part Name: Heater Core / Heating Radiator / Water Tank Radiator.

Function: Transfers heat from the engine coolant to the cabin air to provide heating for the operator. It is also listed as assisting in heating the hydraulic system in certain Hitachi models to ensure optimal operation in cold environments.

Construction: Typically features an all-aluminum tube and fin design with metal or plastic end tanks for durability against the high vibrations of heavy machinery.

24VDC 4301854 Coil for Hitachi & John Deere Excavators – Construction Machinery Spare Part

The 4301854 Coil (24VDC) is a high-performance solenoid valve coil for Hitachi and John Deere excavators, a core component of hydraulic control systems. It converts electrical signals into mechanical force to actuate solenoid valves, precisely controlling hydraulic flow and direction for boom, arm, bucket, and swing movements, ensuring responsive and stable operation of excavator working devices.

· Voltage: 24 VDC

· Power Consumption: 14.7 Watts (some aftermarket versions may vary to 17W)

· Initial Current Draw: 0.61 Amps

· Connector Type: Deutsch DT04-2P (mating connector: Deutsch DT06-2S)

· Internal Protection: Features a built-in bidirectional Zener diode for surge protection

· Coil Size: Fits 08 series HydraForce valves with a 1/2" (12.7mm) inner diameter

Compatibility:

· Equipment Brands: Commonly found in Hitachi and John Deere excavators, as well as HydraForce-compatible systems in harvesting and construction equipment.

Hyundai EXCAVATOR PARTS MADE IN CHINA NEW HX260L 39Q7-12101 SWING REDUCTION GEAR SPARKLING MACHINERY

SPARKLING MACHINERY NEW HX260L 39Q7-12101 Swing Reduction Gear is a core transmission component for Hyundai HX260L excavators (construction/mining use). It reduces engine speed to amplify torque for smooth, precise upper-structure swinging—critical for tasks like material loading.

Meeting Hyundai OEM standards (39Q7-12101), it resists -30°C to 100°C temps, heavy loads, and wear, guaranteeing seamless compatibility with HX260L and long-term reliable swing performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879