SPARKLING Excavator Radiator CAT – Durable, Reliable Cooling

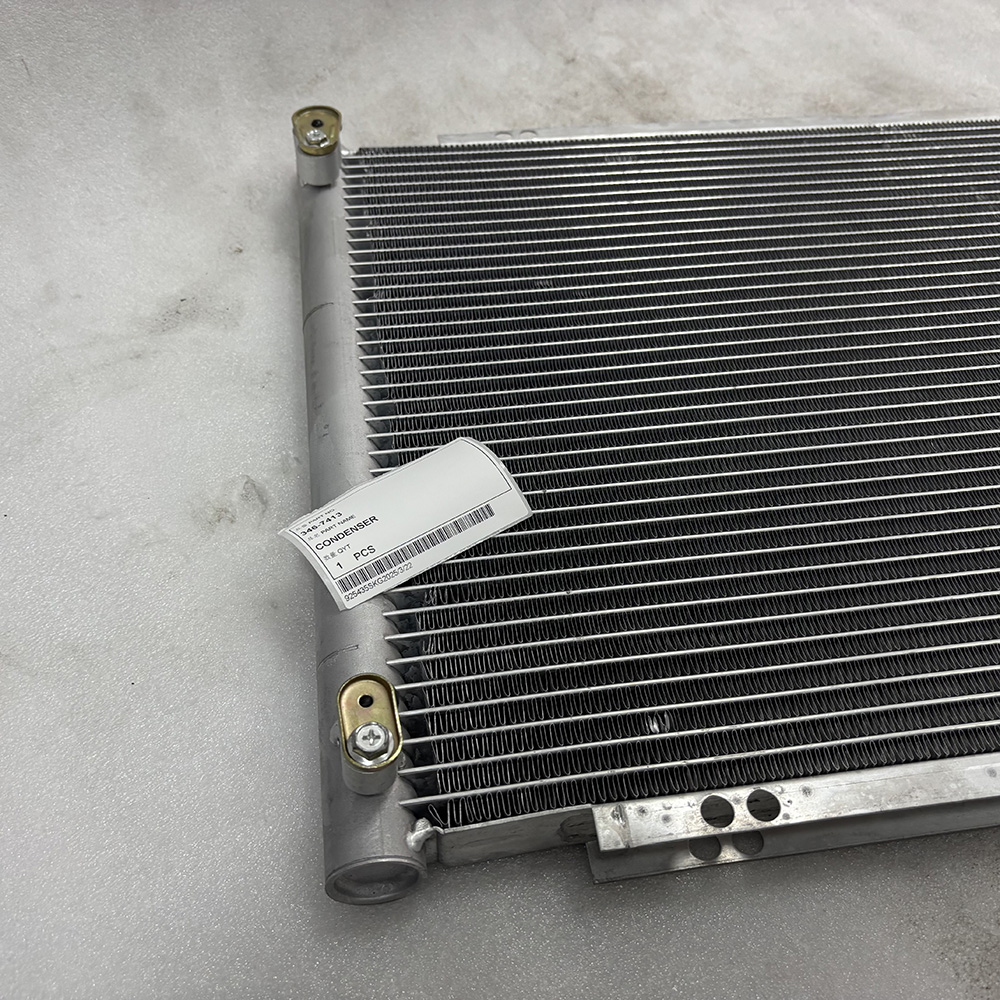

The 346-7413 Condenser Assembly, also known under part numbers CA3467413 and 467413, is a direct-fit refrigerant radiator designed for Caterpillar excavators 316E L, 318E L, 320E, and 320E L.

Manufactured with high-efficiency aluminum fins and durable tubing, this A/C condenser ensures optimal heat exchange, promoting effective cooling of the refrigerant system during high-demand excavation work. Produced by SPARKLING MACHINERY, this aftermarket unit offers excellent performance at a competitive price—perfect for keeping your equipment cool and productive.

SPARKLING Excavator Radiator for CAT – Reliability Meets Precision

SPARKLING MACHINERY, established in 2013, specializes in High Quality excavator parts designed for optimal performance and durability. Our excavator radiator CAT offers unmatched stability and precision, engineered specifically to meet the demanding standards of Caterpillar machinery. Manufactured under strict quality control guidelines, this radiator ensures efficient cooling, preventing engine overheating even in the most challenging working conditions.

As part of SPARKLING’s comprehensive product range—including hydraulic components, undercarriage systems, engine parts, and electrical components—our excavator radiator CAT guarantees compatibility and seamless integration with Caterpillar excavators. We commit to delivering reliable solutions that extend machine life and improve operational efficiency, backed by expert technical support and customized services tailored to your needs.

Trust SPARKLING MACHINERY to provide durable, high-performance excavator radiators that reduce maintenance costs and downtime. Our dedication to innovation, altruism, and quality makes us a preferred partner worldwide. Whether you operate in construction, mining, or agriculture, our excavator radiator CAT will give you peace of mind, ensuring your equipment runs smoothly and reliably.

Choose SPARKLING for quality you can depend on and value that drives your success.

Product Image

FAQ

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

About other questions pls contact me directily.

Caterpillar parts 316E L 318E L 320E 320E L CA3467413 346-7413 467413 CONDENSER AS-REFRIGERANT RADIATOR

The 346-7413 Condenser Assembly, also known under part numbers CA3467413 and 467413, is a direct-fit refrigerant radiator designed for Caterpillar excavators 316E L, 318E L, 320E, and 320E L.

Manufactured with high-efficiency aluminum fins and durable tubing, this A/C condenser ensures optimal heat exchange, promoting effective cooling of the refrigerant system during high-demand excavation work. Produced by SPARKLING MACHINERY, this aftermarket unit offers excellent performance at a competitive price—perfect for keeping your equipment cool and productive.

Komatsu EXCAVATOR PARTS MADE IN CHINA NEW HB205 HB215 PC200 PC210 PC220 PC240 PC290 723-40-94501 RELIEF VALVE SPARKLING MACHINERY

SPARKLING MACHINERY NEW HB205 HB215 PC200 PC210 PC220 PC240 PC290 723-40-94501 Relief Valve is a dedicated hydraulic pressure protection component for Komatsu HB205, HB215, PC200, PC210, PC220, PC240, and PC290 crawler excavators (widely used in construction, mining, and infrastructure projects). As the "hydraulic safety barrier", it automatically relieves excess pressure when it exceeds the set threshold—protecting pumps, cylinders, and hoses from damage during high-intensity tasks like digging, rock breaking, and heavy lifting, while ensuring stable system operation.

Meeting Komatsu OEM standards (part no. 723-40-94501), it maintains a precise pressure range of 28-32 MPa, endures -30°C to 95°C temperatures, resists hydraulic oil corrosion and vibration, and ensures instant pressure relief. Strict testing guarantees seamless compatibility with the seven Komatsu models and long-term hydraulic system safety.

Komatsu HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 421-54-4470 GAS SPARING SPARKLING MACHINERY

SPARKLING MACHINERY NEW 421-54-4470 Gas Sparing is a core fuel-saving component for Komatsu excavators (heavy-duty construction/mining use). It optimizes fuel combustion efficiency, reduces unnecessary fuel consumption, and maintains stable engine power output.

Meeting Komatsu OEM standards (421-54-4470), it resists -30°C to 100°C temps, fuel contamination, and mechanical wear, ensuring seamless compatibility and long-term reliable fuel-saving performance.

CATERPILLAR MADE IN CHINA SPARKLING MACHINERY NEW 416F 420F 422F 273-9190 SWITCH AS-MULTIFUNCTION

SPARKLING MACHINERY NEW 416F 420F 422F 273-9190 Switch AS-Multifunction is a dedicated control component exclusively designed for 416F, 420F, and 422F loaders. As a central part of the loader’s cabin control system, it integrates multiple operational functions into a single, user-friendly interface—allowing operators to seamlessly control key features like work mode selection, auxiliary hydraulic activation, lighting adjustments, and safety lockout. This integrated design simplifies cabin control layout, reduces operational complexity, and enhances response speed, which is critical for maintaining efficiency during tasks such as material loading, site grading, and utility hauling.

Engineered to match original equipment performance standards, it maintains reliable functionality even under harsh working conditions—including cabin vibration, temperature fluctuations, and occasional dust or moisture exposure. It prevents control signal delays or malfunctions, ensuring consistent operation of the loader’s auxiliary systems and safeguarding operator safety. Backed by strict performance verification, it guarantees long-term reliability to support uninterrupted loader operation.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879