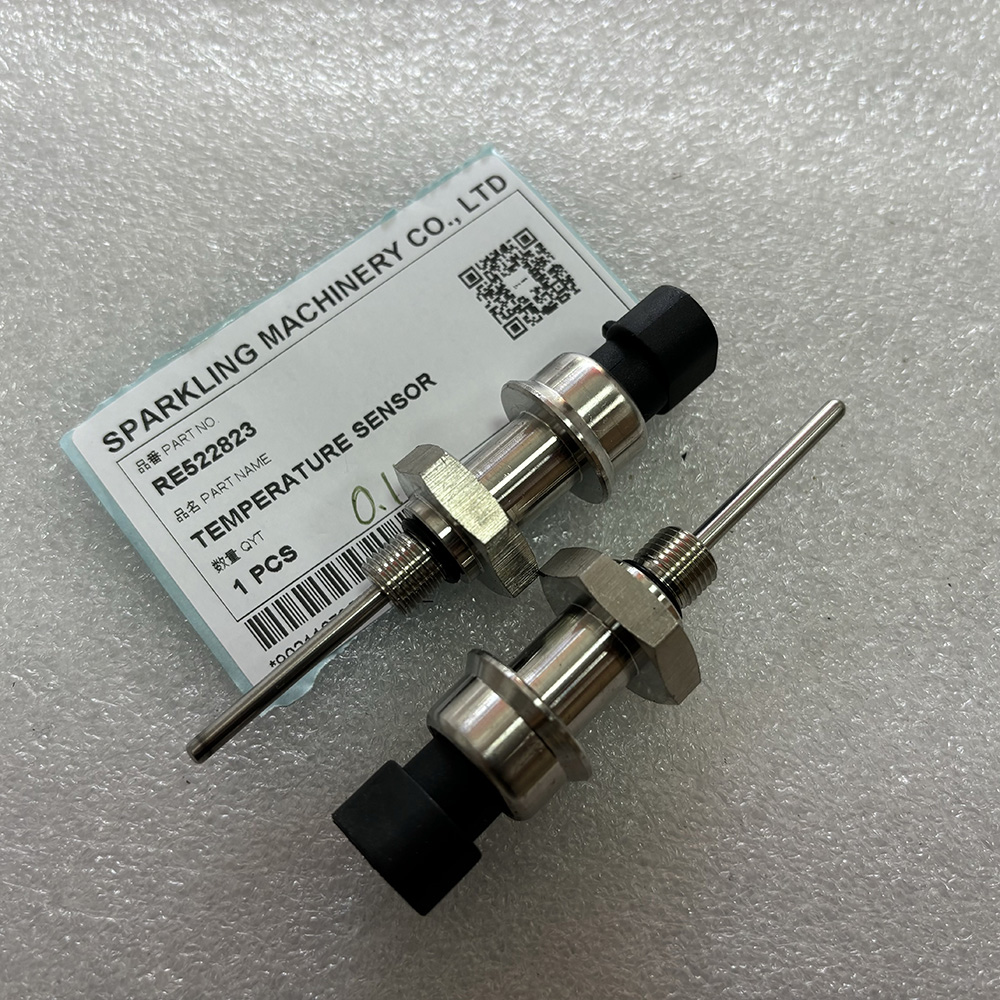

SPARKLING Heavy Equipment Temp Sensor – Precision & Reliability

The John Deere Temperature Sensor (RE522823) is a vital engine and hydraulic monitoring component for mid-to-large John Deere equipment—optimizing operational safety across models like the 1210E, 670G, 290GLC, 755D, 624K, 350DLC, and 953M. Engineered for precise temperature measurement, this two-terminal sensor ensures accurate data feedback to prevent overheating and protect critical engine components. Built to meet or exceed OEM standards, it delivers reliable performance in rugged environments.

SPARKLING Heavy Equipment Temp Sensor – Precision You Can Trust

Since 2013, SPARKLING MACHINERY has stood at the forefront of excavator parts manufacturing, delivering products defined by stability, precision, and durability. Our Heavy Equipment Temp Sensor exemplifies these values, designed specifically to withstand the demanding environments of heavy machinery operations.

This advanced temperature sensor accurately monitors engine and hydraulic temperatures in real-time, helping to prevent overheating and extend equipment lifespan. Compatible with leading brands like Caterpillar, Komatsu, Hitachi, and Volvo, it integrates seamlessly into your heavy equipment, ensuring reliable performance under all conditions.

Crafted through rigorous quality control and state-of-the-art manufacturing, the SPARKLING Heavy Equipment Temp Sensor offers unmatched reliability and responsiveness. It not only enhances operational safety but also optimizes maintenance schedules, reducing downtime and lowering repair costs.

At SPARKLING, we provide customized solutions and dedicated technical support to meet your specific needs. Our comprehensive after-sales service and competitive pricing make us your trusted partner in heavy equipment reliability.

Choose SPARKLING Heavy Equipment Temp Sensor for precision, endurance, and unmatched value – because your machinery deserves the best.

Picture Show

Question you may concern

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

John Deere Temperature Sensor RE522823 – Fits 1210E • 670G • 290GLC • 755D • 624K • 350DLC • 953M

The John Deere Temperature Sensor (RE522823) is a vital engine and hydraulic monitoring component for mid-to-large John Deere equipment—optimizing operational safety across models like the 1210E, 670G, 290GLC, 755D, 624K, 350DLC, and 953M. Engineered for precise temperature measurement, this two-terminal sensor ensures accurate data feedback to prevent overheating and protect critical engine components. Built to meet or exceed OEM standards, it delivers reliable performance in rugged environments.

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EC240B EC240C EC290B EC290C VOE21814758 CABLE HARNESS SPARKLING MACHINERY

SPARKLING MACHINERY NEW EC240B EC240C EC290B EC290C VOE21814758 Cable Harness is a dedicated electrical connection component for VOLVO EC240B, EC240C, EC290B, and EC290C crawler excavators (widely used in construction, mining, and large-scale infrastructure projects). As the "electrical communication backbone" of the excavator, it transmits stable electrical signals between core components—such as ECUs, sensors, hydraulic valves, and cab instruments—to ensure smooth operation of critical functions like engine control, precision digging, and track movement during high-intensity tasks.

Meeting VOLVO OEM standards (part no. VOE21814758), it endures -30°C to 85°C temperature fluctuations, resists moisture, dust, and mechanical abrasion, and maintains reliable insulation. Strict performance testing guarantees seamless compatibility with the four VOLVO models and long-term stable signal transmission.

High-Performance 343-3677 Joystick Base for Caterpillar Excavators | Fits CAT E374D, 365C, 385C, 390D

· Function: It serves as the mounting and support mechanism for the joystick control inputs, integrating a robust mechanical interface with the necessary electrical wiring.

· Design: The assembly includes a base and wiring harness with a 6-pin DT connection and a straight mounting tube.

· Durability: Made from high-quality, durable materials like steel casting, it is built to withstand the demands of heavy-duty construction, energy, and mining applications. It is also RoHS compliant.

Compatible Equipment

The 343-3677 joystick base is designed to fit several models of Cat equipment, including:

· Excavators: Compatible with models such as the E374D, 365C, 385C, 390D, 320GC, 323GX, and 336GC.

· Track-Type Tractors: Used in D6K, D4K, and D5K track-type tractors.

· Wheel Loaders: Some models, such as the SEM816, utilize this assembly.

KOMATSU HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW SAA6D114E WA430 6745-81-9240 HARNESS SPARKLING MACHINERY

SPARKLING MACHINERY NEW 6745-81-9240 Harness is a core electrical connection component for Komatsu SAA6D114E/WA430 excavators (construction/mining use). It transmits electrical signals and power between key systems, ensuring stable communication and operation.

Meeting Komatsu OEM standards (6745-81-9240), it resists -30°C to 100°C temps, abrasion, and moisture, guaranteeing seamless compatibility and reliable long-term electrical performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879