SPARKLING Hydraulic Heat Exchanger for Hyundai Excavators – Durable & Efficient

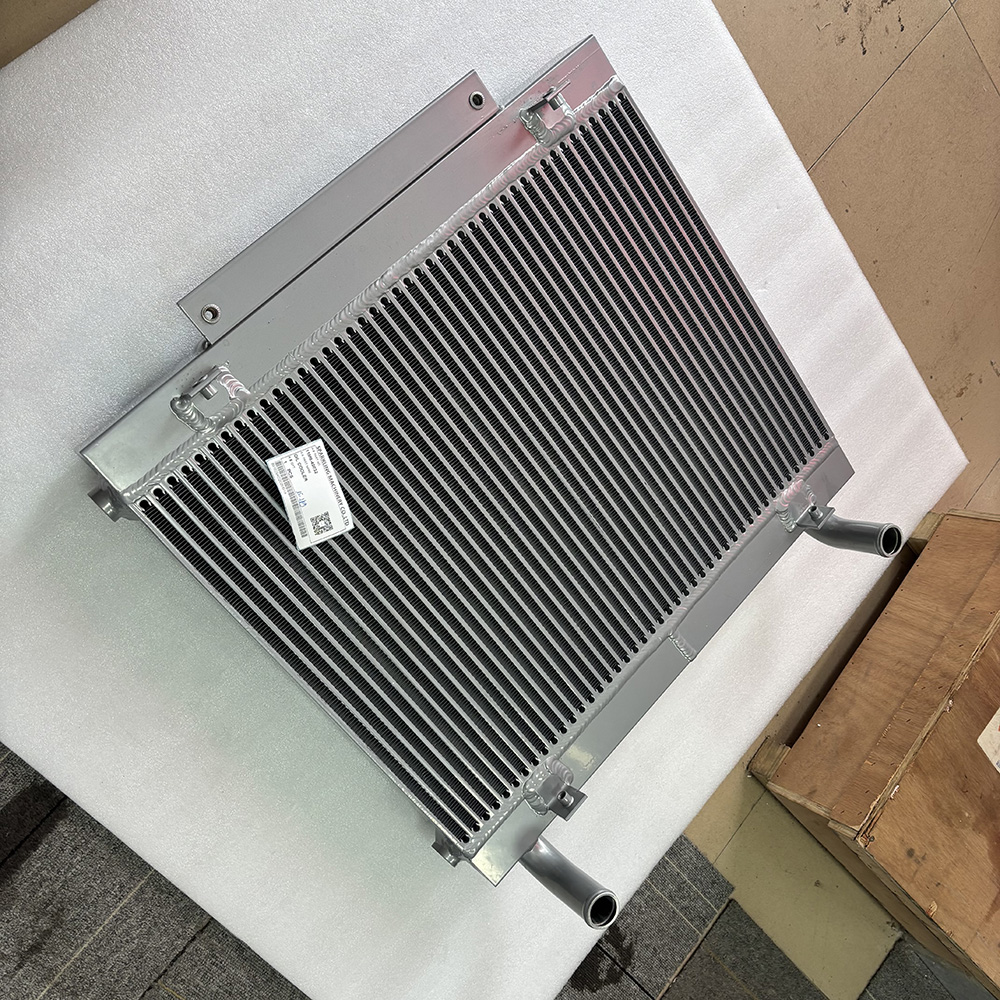

The Hydraulic Oil Cooler Assembly (part no. 11M8‑40032 / 11M8‑43120) is a high-efficiency, all‑aluminum plate‑fin heat exchanger engineered for Hyundai compact excavators—specifically R55‑7 and R55W‑7 (also fitting R60‑7). Built free of epoxy, this OEM‑spec cooler ensures optimal heat dissipation and withstands continuous high pressure (up to 2 MPa), making it a reliable drop‑in replacement for demanding operation environments

The SPARKLING Hydraulic Heat Exchanger for Hyundai excavators is engineered to deliver superior cooling efficiency and reliable performance in harsh working conditions. Designed with precision and built from High Quality materials, this heat exchanger ensures your excavator’s hydraulic system remains at optimal temperatures, preventing overheating and extending the lifespan of critical components.

At SPARKLING MACHINERY, founded in 2013, we specialize in high-quality excavator parts, combining stability and durability with innovative design. Our hydraulic heat exchanger for Hyundai models undergoes strict quality control to guarantee durability and consistent performance, even during intensive operations.

This product offers a direct fit replacement that meets or exceeds original equipment manufacturer (OEM) standards. With excellent corrosion resistance and efficient heat dissipation, it minimizes downtime and maintenance needs, keeping your equipment running smoothly on-site.

By choosing SPARKLING, you benefit from our comprehensive technical support and customized solutions tailored to your needs. Our competitive pricing does not compromise quality, helping you reduce operational costs without sacrificing reliability.

Compatible with multiple Hyundai excavator models, this hydraulic heat exchanger is an ideal choice for operators seeking both performance and value in their machinery parts.

Upgrade your equipment with SPARKLING Hydraulic Heat Exchanger — where precision meets endurance to maximize your excavator’s productivity.

Detailed display

FAQ

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Hyundai Oil Cooler Assy 11M8‑40032 / 11M8‑43120 for R55‑7 & R55W‑7 Excavators

The Hydraulic Oil Cooler Assembly (part no. 11M8‑40032 / 11M8‑43120) is a high-efficiency, all‑aluminum plate‑fin heat exchanger engineered for Hyundai compact excavators—specifically R55‑7 and R55W‑7 (also fitting R60‑7). Built free of epoxy, this OEM‑spec cooler ensures optimal heat dissipation and withstands continuous high pressure (up to 2 MPa), making it a reliable drop‑in replacement for demanding operation environments

KOMATSU EXCAVATOR PARTS MADE IN CHINA NEW PC27MR PC27MRX PC28UU PC30MR PC30MRX 708-1S-13370/708-3S-13370 GUIDE, RETAINER SPARKLING MACHINERY

KOMATSU HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW BR200S BR550JG BR580JG PC270 PC270LL 702-75-04600 RELIEF VALVE SPARKLING MACHINERY

SPARKLING MACHINERY NEW BR200S BR550JG BR580JG PC270 PC270LL 702-75-04600 Relief Valve is a core hydraulic safety component for Komatsu BR200S/BR550JG/BR580JG/PC270/PC270LL excavators (heavy-duty construction/mining use). It regulates and limits maximum hydraulic system pressure to prevent overload damage to pumps, hoses, and actuators.

Meeting Komatsu OEM standards (702-75-04600), it resists -30°C to 100°C temps, pressure fluctuations, and contamination, ensuring seamless compatibility and long-term reliable pressure protection.

Caterpillar EXCAVATOR PARTS MADE IN CHINA NEW DL200 DL250 DL300 DL400 DL500 301419-00106/K1001858A IGNITION SWITCH SPARKLING MACHINERY

SPARKLING MACHINERY NEW DL200 DL250 DL300 DL400 DL500 301419-00106 K1001858A Ignition Switch is a core startup component for 5 Caterpillar excavator models (construction/mining use). It controls engine ignition and power supply to key systems, ensuring safe and reliable startup. Meeting Caterpillar OEM standards (301419-00106/K1001858A), it resists -30°C to 85°C temps, moisture, and vibration, guaranteeing seamless compatibility and long-term performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879