SPARKLING Hydraulic Pump for JCB Loader – Durable & Precise

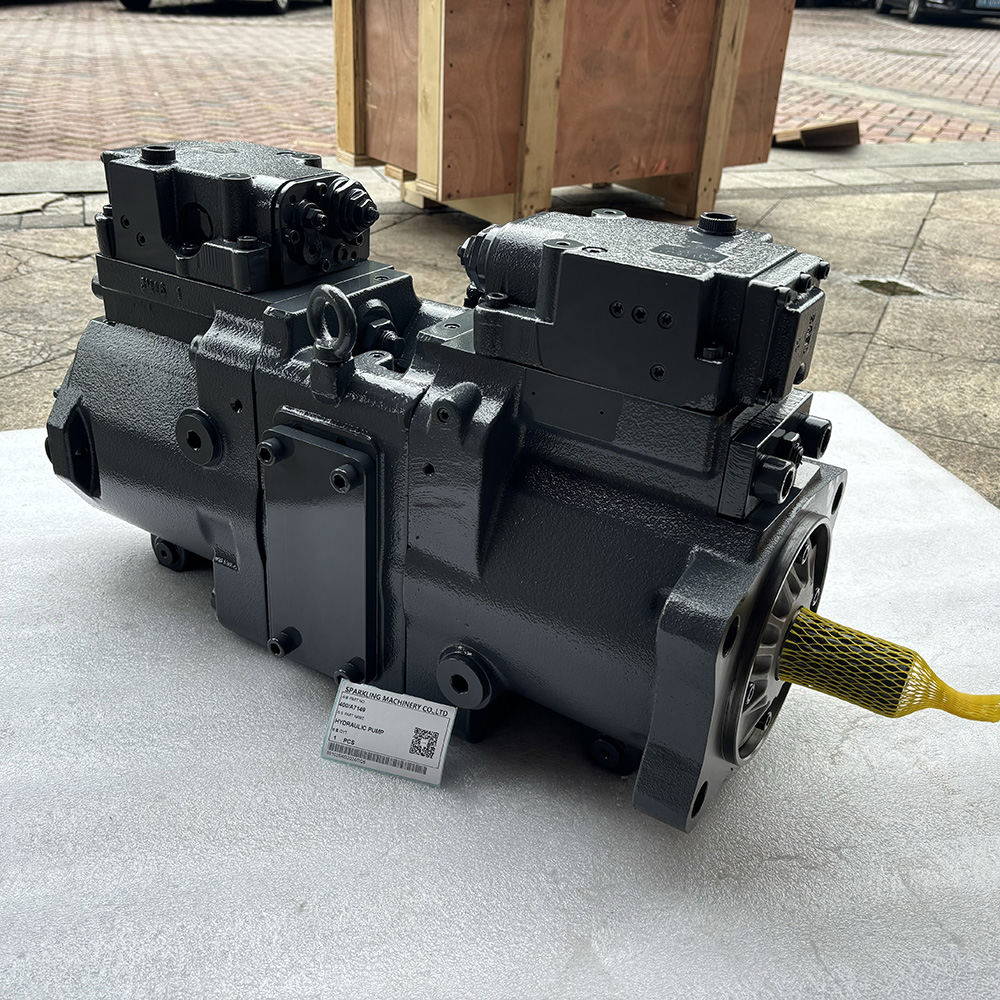

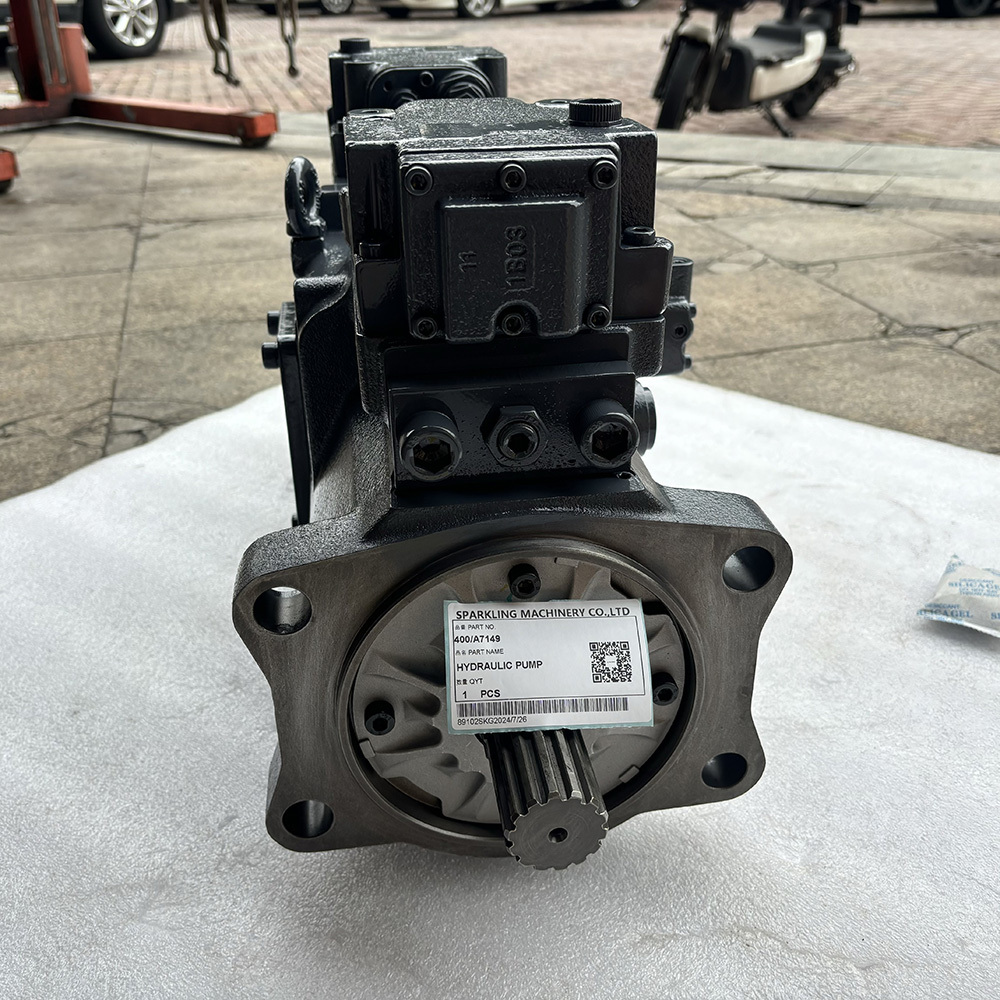

The 400/A7149 Hydraulic Main Pump Assembly is a high-efficiency, China-manufactured replacement pump designed to match or exceed original JCB standards. Engineered with precision and built using upgraded internal components, this pump ensures strong flow delivery, stable pressure, and reliable performance in heavy-duty construction and excavation applications.

It is a direct-fit solution for JCB models using this pump reference, providing excellent value without compromising on quality. Each unit is 100% factory-tested to guarantee durability and smooth operation under tough working conditions.

SPARKLING Hydraulic Pump for JCB Loader – Precision and Reliability You Can Trust

Introducing the SPARKLING hydraulic pump for JCB loader—designed to deliver exceptional performance, durability, and efficiency for your heavy machinery needs. Since 2013, SPARKLING MACHINERY has been committed to providing high-quality excavator parts, focusing on stability, precision, and perseverance to meet and exceed customer expectations.

Our hydraulic pump is engineered with advanced technology and stringent quality controls to ensure smooth operation and consistent hydraulic power under diverse working conditions. Compatible specifically with JCB loaders, it optimizes machine functionality and prolongs service life, minimizing downtime and maintenance costs. Every pump undergoes meticulous testing to guarantee reliability and excellence.

At SPARKLING MACHINERY, we care about your operational success. That’s why we offer not only High Quality products but also tailored customer support and customized solutions—helping you maintain peak productivity effortlessly. Our competitive pricing combined with unwavering quality ensures you get outstanding value without compromise.

Backed by a global sales network and comprehensive technical assistance, the SPARKLING hydraulic pump is your trusted choice for sustained performance. As part of a broader product range including hydraulic components, undercarriage systems, engine parts, and more, our pump fits seamlessly into your maintenance plans.

Choose SPARKLING hydraulic pump for your JCB loader and experience dependable power, innovative engineering, and a partner who truly values your business. Let us help you reduce costs while maximizing efficiency, so you can keep your projects moving forward with confidence.

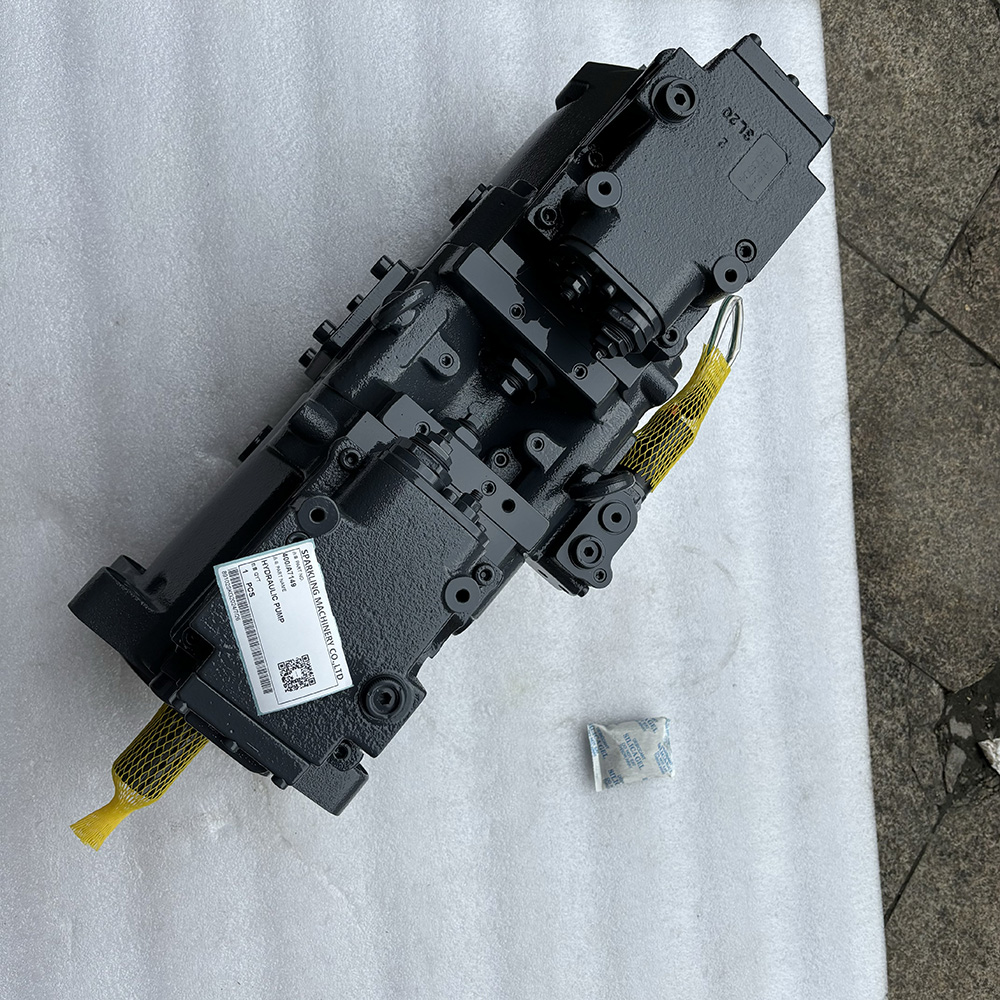

Product Image

Frequently Asked Questions

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

JCB 400/A7149 HYDRAULIC MAIN PUMP ASSY CHINA MADE BETTER QUALITY

The 400/A7149 Hydraulic Main Pump Assembly is a high-efficiency, China-manufactured replacement pump designed to match or exceed original JCB standards. Engineered with precision and built using upgraded internal components, this pump ensures strong flow delivery, stable pressure, and reliable performance in heavy-duty construction and excavation applications.

It is a direct-fit solution for JCB models using this pump reference, providing excellent value without compromising on quality. Each unit is 100% factory-tested to guarantee durability and smooth operation under tough working conditions.

KOMATSU MADE IN CHINA SPARKLING MACHINERY NEW 3078150 SENSOR

SPARKLING MACHINERY NEW 3078150 Sensor is a dedicated precision detection component tailored for compatible heavy-duty construction machinery, such as excavators and loaders. As a core part of the machinery’s operational monitoring system, it real-time collects critical data—including hydraulic pressure, engine temperature, or component position—and transmits accurate signals to the machinery’s control unit. This function is essential for enabling the control system to adjust operations dynamically during heavy-duty tasks like digging, lifting, and grading, directly ensuring stable machinery performance, preventing overloading or overheating, and reducing the risk of unexpected component damage.

Engineered to match original equipment performance standards, it maintains high signal accuracy and stable operation even under harsh working conditions, including continuous vibration, dust exposure, temperature fluctuations (-30°C to 80°C), and hydraulic oil contamination. It resists signal interference and mechanical wear, avoiding data errors or transmission failures that could lead to operational delays or safety hazards. Backed by strict performance verification, it guarantees reliable data feedback to support uninterrupted operation of compatible heavy-duty machinery.

Caterpillar MADE IN CHINA SPARKLING MACHINERY NEW 324F 329E 349E 372-9368 FAN

SPARKLING MACHINERY NEW 324F 329E 349E 372-9368 Fan is a premium China-made cooling system component specifically engineered for 324F, 329E, and 349E excavators. As a core part of the machinery’s engine and hydraulic cooling system, it generates consistent airflow to dissipate heat from the radiator, hydraulic oil cooler, and intercooler—critical for preventing overheating during heavy-duty operations like deep digging, high-load lifting, and continuous mining. This ensures the engine and hydraulic system maintain optimal operating temperatures, safeguarding performance stability and extending component service life.

Designed to original equipment standards, it delivers reliable airflow even under harsh working conditions, including high ambient temperatures (up to 50°C), dust, and vibration from rugged terrain. With optimized blade geometry for efficient air circulation and a robust hub structure for stable rotation, it integrates seamlessly into the excavators’ cooling system. Backed by strict quality verification, it guarantees consistent cooling performance to support uninterrupted work cycles and reduce downtime caused by overheating-related failures.

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 302.7D 386-0875 3860875 RELIEF VALVE SPARKLING MACHINERY

SPARKLING MACHINERY's new 386-0875 (3860875) Relief Valve is a core hydraulic system component specifically designed for Caterpillar 302.7D excavators, suitable for construction and mining applications. It regulates and stabilizes hydraulic system pressure, preventing overpressure damage to hydraulic components.

Compliant with Caterpillar OEM standards (Part No.: 386-0875 / 3860875), this component exhibits excellent pressure control accuracy and sealing performance, ensuring seamless compatibility with original equipment and long-term reliable operational performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879