SPARKLING Hydraulic Replacement Parts for Excavators – Reliable & Precise

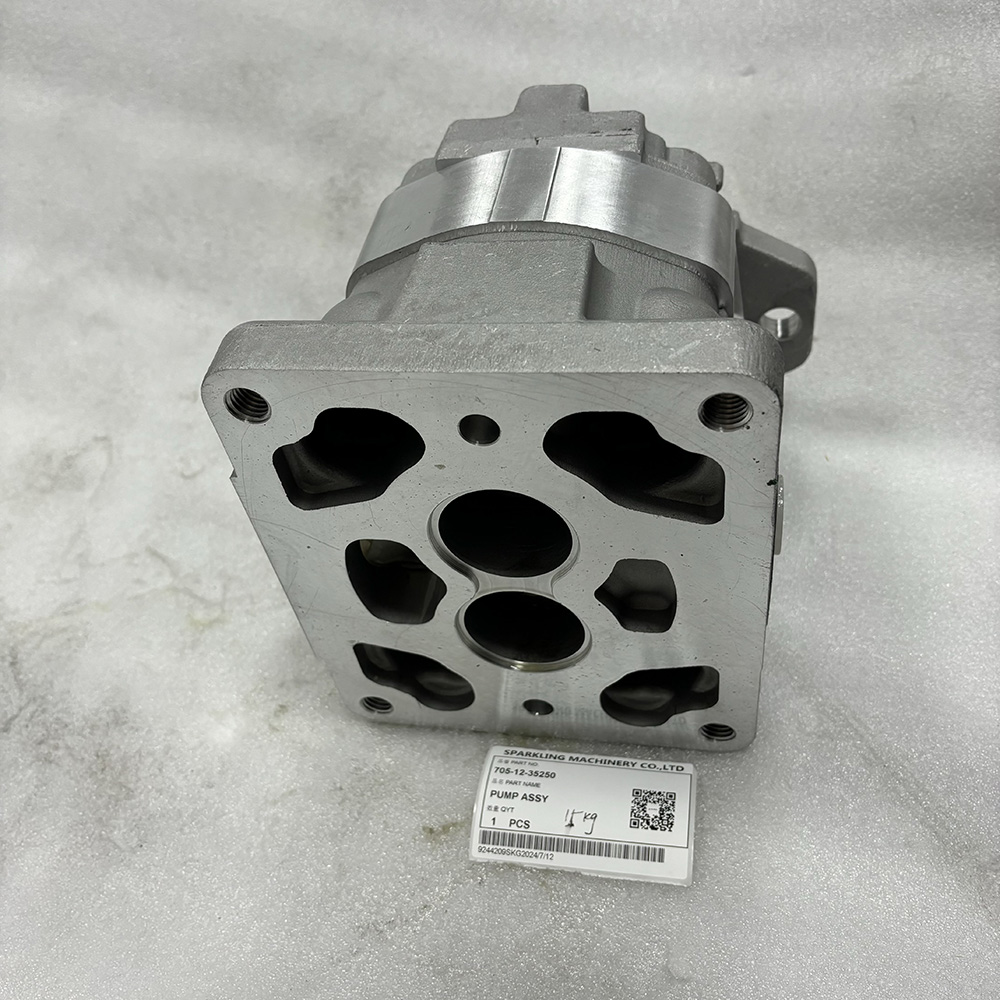

The 705-12-35250 Gear Pump Assembly is a critical hydraulic component designed for KOMATSU HM400-3R Articulated Dump Trucks. This gear pump plays a vital role in ensuring smooth and efficient hydraulic flow for critical systems, including steering, braking, and body lifting functions.

Manufactured with high-precision machining and quality-tested materials, the 7051235250 gear pump offers excellent reliability, extended service life, and consistent performance under extreme working conditions. Whether you're replacing a worn-out unit or conducting scheduled maintenance, SPARKLING MACHINERY's aftermarket gear pump ensures optimal compatibility and long-term value.

SPARKLING Hydraulic Replacement Parts – Precision and Reliability You Can Trust

Since 2013, SPARKLING MACHINERY has been a dedicated leader in providing high-quality hydraulic replacement parts tailored for excavators. Engineered with a focus on stability, precision, and durability, our hydraulic components are designed to meet the demanding requirements of heavy machinery operation. Whether you operate Caterpillar, Komatsu, Hitachi, Volvo, or other leading brands, SPARKLING offers a comprehensive selection of parts compatible with your equipment, ensuring seamless integration and optimal performance.

At SPARKLING, we understand that downtime can be costly. That’s why each hydraulic replacement part undergoes rigorous manufacturing processes and stringent quality control to guarantee reliable operation under diverse working conditions. Our commitment extends beyond just supplying parts; we provide customized solutions and expert technical support, guiding you through product selection and maintenance to maximize efficiency.

Our extensive product range also includes undercarriage systems, engine and electrical components, cabs, mini excavators, and accessories, making SPARKLING your one-stop partner for all excavator needs. With a global sales network and competitive pricing, we are dedicated to helping customers reduce operating costs without compromising on quality.

Choose SPARKLING MACHINERY – where innovation meets altruism, and every hydraulic replacement part is a testament to excellence. Experience stability, precision, and unmatched customer care backed by years of expertise. Let us help you keep your excavators running smoothly and efficiently.

Detailed display

Frequently Asked Questions

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

If you have any other questions, please write email to us or call us , we will reply you as soon as possible.

705-12-35250 Gear Pump for KOMATSU HM400-3R Dump Truck | Hydraulic Pump Assembly

The 705-12-35250 Gear Pump Assembly is a critical hydraulic component designed for KOMATSU HM400-3R Articulated Dump Trucks. This gear pump plays a vital role in ensuring smooth and efficient hydraulic flow for critical systems, including steering, braking, and body lifting functions.

Manufactured with high-precision machining and quality-tested materials, the 7051235250 gear pump offers excellent reliability, extended service life, and consistent performance under extreme working conditions. Whether you're replacing a worn-out unit or conducting scheduled maintenance, SPARKLING MACHINERY's aftermarket gear pump ensures optimal compatibility and long-term value.

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 GEAR-COUPLING SPARKLING MACHINERY

SPARKLING MACHINERY NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 Gear-Coupling is a core power transmission component for 3 Hyundai excavator models (construction/mining use). It connects and transmits torque between mechanical shafts, absorbing vibration and compensating for alignment deviations.

Meeting Hyundai OEM standards (XKAH-00360), it resists -30°C to 100°C temps, wear, and impact, guaranteeing seamless compatibility and long-term reliable transmission performance.

SPARKLING Front Drive Shaft for Komatsu PC200-8 PC228US-8 PC270-8 Excavator for Main Pump HPV95 Shaft 708-2L-32160

The Front Drive Shaft (Part No. 708-2L-32160) is a precision-engineered component designed for Komatsu excavators PC200-8, PC228US-8, and PC270-8, compatible with the HPV95 hydraulic pump.

Manufactured from high-strength alloy steel and processed with strict quality control, this drive shaft ensures reliable torque transmission, smooth rotation, and long-term durability in heavy-duty working environments. It is produced to match OEM specifications, making it a dependable replacement for original Komatsu parts.

With a net weight of 3.1 kg, this front drive shaft offers excellent mechanical balance, helping to reduce vibration and wear on related hydraulic components. It is ideal for excavator maintenance, repair, and hydraulic system overhaul.

Brand: SPARKLING MACHINERY

Condition: New

Weight: 3.1 kg

Part Number: 708-2L-32160

401-00331 Final Drive Gearbox with Travel Motor for Doosan Daewoo S340LC-V S330LC-V

SPARKLING MACHINERY NEW S340LC-V 401-00331 Travel Reducer is a core power transmission component exclusively for Doosan S340LC-V excavators (heavy-duty construction/mining use). It reduces speed and amplifies torque for stable track movement, critical for heavy-load and rough-terrain operations.

Part number 401-00331 identifies a Final Drive Gearbox with Travel Motor (also referred to as a propel motor or travel device assembly) primarily used in heavy excavators.

Compatible Machines

This part is specifically designed for the following Doosan and Daewoo crawler excavator models:

Solar 340LC-V (S340LC-V)、Solar 330LC-V (S330LC-V)、Solar 340LC-7

Technical Specifications

Weight: 458kg

Components: Includes a complete assembly of the hydraulic travel motor and the gear reduction sections.

Alternative Part Numbers: This component may also be listed as 401-00331A, 401-00331B, or replace older numbers such as 2401-9264C and 170401-00027.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879