SPARKLING Hyundai Excavator Check Valve - Durable & Precise

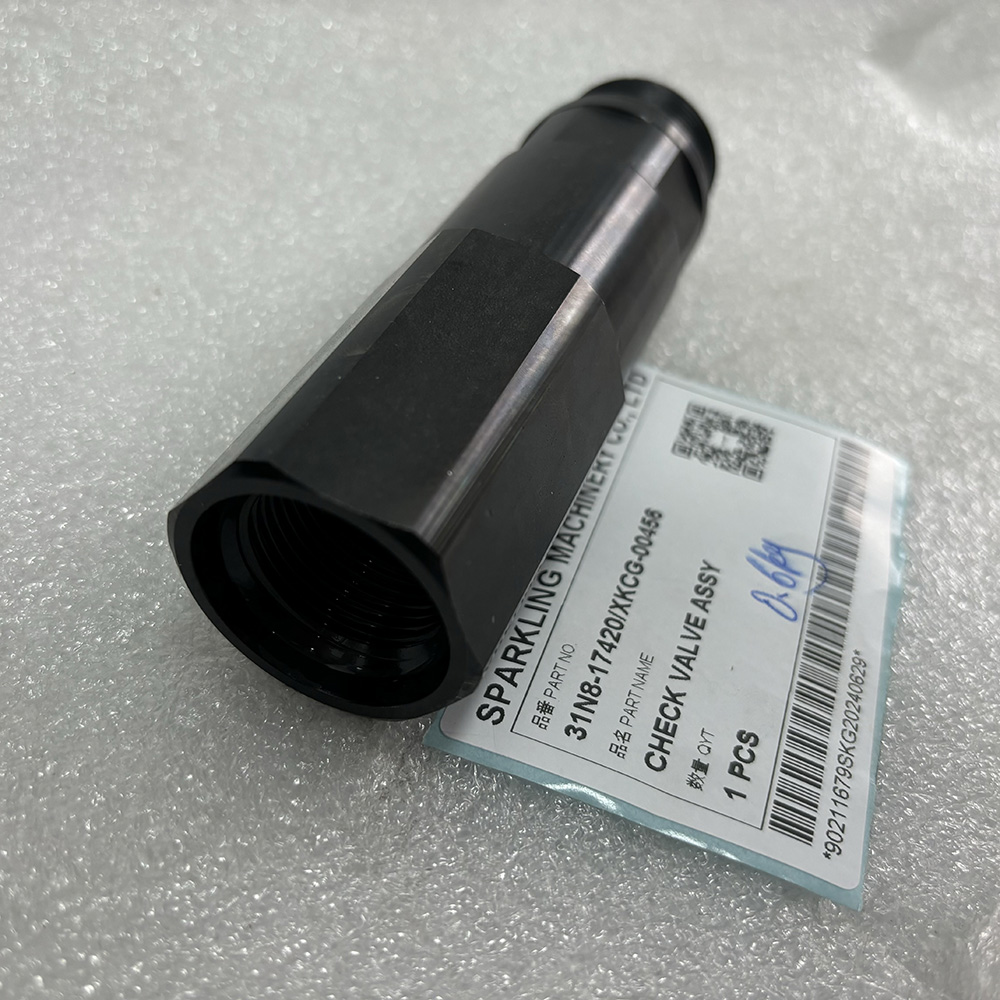

The HYUNDAI Check Valve 31N8-17420 / XKCG-00456 is a genuine replacement component designed for the main control valve system of Hyundai 9-Series crawler excavators, specifically model R300LC-9.

This check valve plays a critical role in hydraulic flow control. It allows fluid to move in one direction while preventing backflow, which protects the hydraulic system from pressure surges and maintains stable performance during demanding excavation operations.

Manufactured to OEM specifications, this valve offers precision engineering, corrosion resistance, and a durable internal seal — ensuring reliable operation, even under extreme pressure and high-duty cycles. It's ideal for both routine maintenance and emergency repairs when performance and safety are non-negotiable.

SPARKLING Hyundai Excavator Check Valve – Reliable Precision for Optimal Performance

When it comes to maintaining the efficiency and durability of your Hyundai excavator, the SPARKLING Hyundai excavator check valve is an essential component designed with precision and reliability in mind. Manufactured by SPARKLING MACHINERY, a trusted name since 2013, this check valve ensures optimal hydraulic system performance by preventing backflow and maintaining consistent pressure, critical for smooth excavation operations.

Crafted with high-quality materials and undergoes rigorous quality controls, the SPARKLING Hyundai excavator check valve is built to withstand harsh working environments and prolonged use. Compatible seamlessly with Hyundai excavators, this valve guarantees a perfect fit and hassle-free installation, minimizing downtime and maximizing productivity for both professionals and heavy machinery operators.

SPARKLING MACHINERY prides itself on providing not just parts but comprehensive solutions. Our Hyundai excavator check valve is part of an extensive range of excavator components, including hydraulic systems, undercarriages, engine parts, and more, all tailored to meet the demands of leading brands like Caterpillar, Komatsu, Hitachi, and Volvo. We offer dedicated technical support and customized consultation, reflecting our commitment to helping customers reduce operational costs while maintaining equipment excellence.

By choosing SPARKLING, you invest not only in a high-quality Hyundai excavator check valve but also in a partnership that values stability, precision, and innovation. Experience superior performance and prolonged machinery life with SPARKLING’s trusted solutions designed for your peace of mind.

Picture Show

Question you may concern

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Hyundai 31N8-17420 / XKCG-00456 Check Valve | R300LC-9 Excavator Main Control Valve Part

The HYUNDAI Check Valve 31N8-17420 / XKCG-00456 is a genuine replacement component designed for the main control valve system of Hyundai 9-Series crawler excavators, specifically model R300LC-9.

This check valve plays a critical role in hydraulic flow control. It allows fluid to move in one direction while preventing backflow, which protects the hydraulic system from pressure surges and maintains stable performance during demanding excavation operations.

Manufactured to OEM specifications, this valve offers precision engineering, corrosion resistance, and a durable internal seal — ensuring reliable operation, even under extreme pressure and high-duty cycles. It's ideal for both routine maintenance and emergency repairs when performance and safety are non-negotiable.

Hyundai MADE IN CHINA SPARKLING MACHINERY NEW R140W7 R140W7A R140W9 ZTAM-00571 FLANGE

SPARKLING MACHINERY NEW R140W-7 R140W-7A ZTAM-00571 Flange is a premium China-made structural component specifically engineered for R140W-7 and R140W-7A wheel excavators. As a critical connecting element in mechanical systems, it provides stable and secure joining of key components such as hydraulic pipelines, transmission shafts, and structural parts, ensuring reliable force transmission and system integrity during heavy-duty operations.

Designed to original equipment standards, it maintains precise dimensional accuracy and high load-bearing capacity, even under continuous vibration and stress. Crafted with robust structural design and corrosion-resistant properties, it adapts to harsh working environments, from muddy construction sites to humid conditions. Backed by strict quality verification, it ensures consistent performance to support uninterrupted machinery operation.

ZGAQ-02885 AXLE-DIFFERENTIAL for Hyundai R140W-9 R160W-9A R170W-9 R180W-9S | SPARKLING MACHINERY

The ZGAQ-02885 AXLE-DIFFERENTIAL is a high-performance replacement component designed for Hyundai wheel excavators R140W-9, R160W-9A, R170W-9, and R180W-9S. As the heart of the machine's drive system, the differential ensures power is efficiently distributed to the wheels, enabling smooth turns, stable operation, and strong traction even in demanding terrains.

Manufactured with high-precision machining and heavy-duty materials, this differential unit is engineered to match OEM specifications and withstand the harsh conditions of construction, mining, and industrial applications. It is an ideal choice for restoring full drivetrain performance and reliability in your equipment.

China Made Hyundai Construction Equipment Spare Parts Used on R200W-7 R200W-3 ZGAQ-01268 Hub-axle Hub

SPARKLING China-made Hub-axle for Hyundai Construction Equipment, compatible with R200W-7 and R200W-3 models. This durable excavator axle hub ensures reliable performance and easy installation. Optimize your machinery with high-quality spare parts designed for longevity and strength.

The product number ZGAQ-01268 refers to a hub-axle used in Hyundai wheel excavators, specifically models like the R200W-7, R200W/R200W-2, and R200W-3.

The ZGAQ-01268 is an excavator axle spare part that helps connect the wheel to the axle assembly. It is often available from aftermarket parts suppliers and is designed to fit specific Hyundai heavy machinery models.

Part Name: Hub-axle or Hub

Manufacturer: Hyundai Construction Equipment (OEM part number)

Compatible Excavator Models: R200W-7, R200W-3, R200W/R200W-2, R140W-9 (and related series like 9A, 9S)

Weight: Approximately 22.1 KG (kilograms) according to buyaftermarketparts.com.

Alternate Part Numbers: It can also be referred to by the part number 4472-320-094.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879