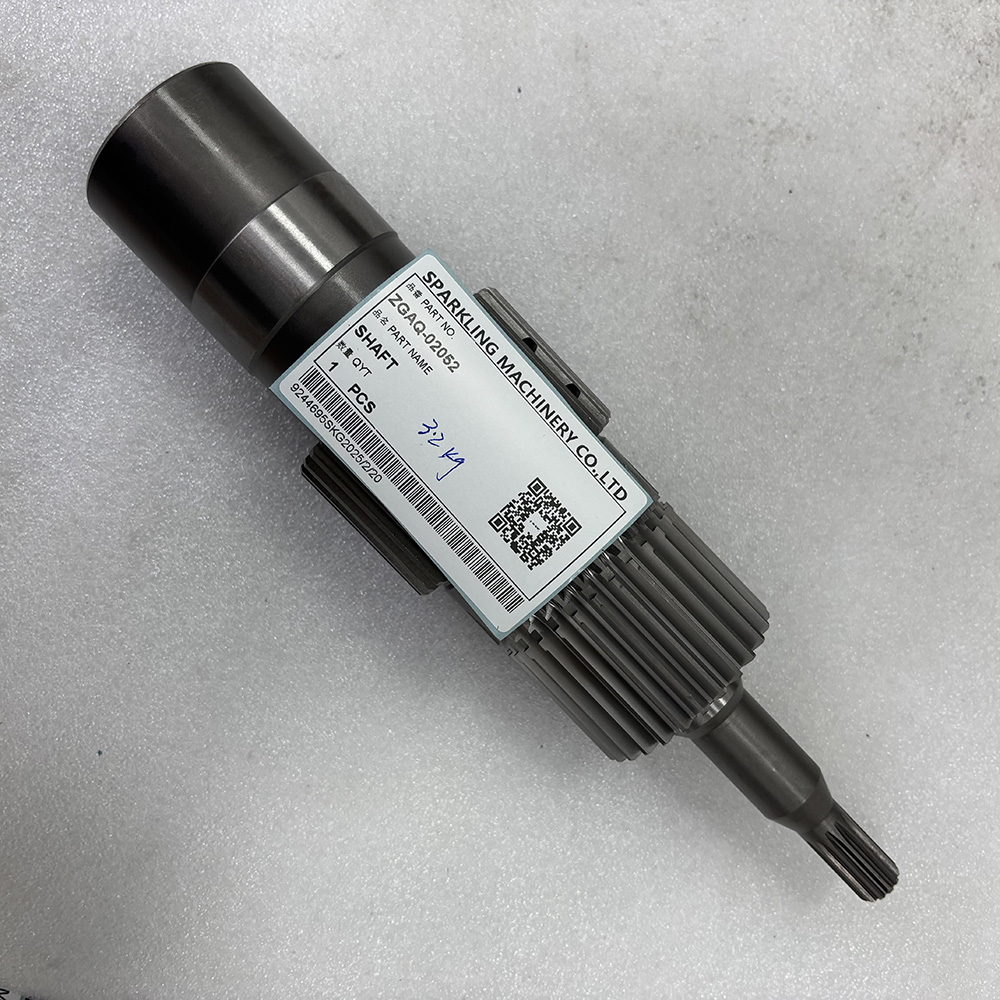

SPARKLING HYUNDAI Input Shaft – Reliable Excavator Part

The ZGAQ-02052 Shaft-Input is a critical drivetrain component specifically designed for HYUNDAI Wheel Excavators, including models R140W-7, R140W-9A, R140W-9S, R170W-7, and R170W-7A. This input shaft is responsible for transmitting torque efficiently from the transmission to the differential or gearbox, ensuring smooth and reliable machine operation.

Manufactured with high-grade alloy steel and precision machining, the ZGAQ-02052 offers excellent durability, high-load resistance, and long service life — even under the harsh conditions of construction and excavation environments.

SPARKLING HYUNDAI Input Shaft

At SPARKLING MACHINERY, we understand the critical role every excavator part plays in ensuring smooth, efficient operation. Our HYUNDAI input shaft is engineered with precision and crafted from High Quality materials to deliver exceptional durability and reliable performance. Designed to meet and exceed OEM standards, this input shaft seamlessly fits HYUNDAI excavators, ensuring optimal compatibility and longevity under demanding conditions.

Backed by SPARKLING’s decade-long expertise in producing high-quality excavator components, our HYUNDAI input shaft is subjected to rigorous manufacturing processes and strict quality control to guarantee stability and resistance against wear and tear. Whether you operate in construction, mining, or heavy-duty excavation, this component offers outstanding torque transmission, helping reduce downtime and maintenance costs.

We prioritize our customers by providing tailored solutions, along with professional technical support and consultation to ensure you get the most efficient and cost-effective parts for your equipment. Our commitment to altruism and innovation drives us to continuously improve, offering products that not only perform well but also support your business goals. With competitive pricing and a global sales network, SPARKLING MACHINERY is your trusted partner in maintaining your HYUNDAI excavators at peak performance.

Choose the SPARKLING HYUNDAI input shaft for reliability, durability, and unmatched value in excavator parts.

Detailed display

Question you may concern

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

HYUNDAI WHEEL EXCAVATOR R140W-7 R140W-9A R140W-9S R170W-7 R170W-7A ZGAQ-02052 SHAFT-INPUT

The ZGAQ-02052 Shaft-Input is a critical drivetrain component specifically designed for HYUNDAI Wheel Excavators, including models R140W-7, R140W-9A, R140W-9S, R170W-7, and R170W-7A. This input shaft is responsible for transmitting torque efficiently from the transmission to the differential or gearbox, ensuring smooth and reliable machine operation.

Manufactured with high-grade alloy steel and precision machining, the ZGAQ-02052 offers excellent durability, high-load resistance, and long service life — even under the harsh conditions of construction and excavation environments.

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R55-3 31M6-50031 HYD PUMP SPARKLING MACHINERY

SPARKLING MACHINERY NEW R55-3 31M6-50031 Hydraulic Pump (HYD PUMP) is a core power component exclusively for Hyundai R55-3 excavators (construction/mining use). It supplies stable hydraulic pressure to drive arms, buckets, and travel systems.

Meeting Hyundai OEM standards (31M6-50031), it resists -30°C to 100°C temps, high pressure, and wear, ensuring seamless compatibility and long-term reliable hydraulic power delivery.

Excavator Spare Parts 221-8318 VALVE AS-BRA for Cat Heavy Machinery 735 735B 740 740B

KOMATSU HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW D155AX D65EX D65PX HB205 HB215 ND116420-7450 HEATER CORE SPARKLING MACHINERY

SPARKLING MACHINERY NEW ND116420-7450 Heater Rad Set is a core climate control assembly for Komatsu D155AX/D65EX/D65PX/HB205/HB215 excavators (construction/mining use). It integrates a heater radiator and matching components, heating cabin air via engine coolant circulation to ensure comfortable and safe operation in low temperatures.

Excavators: PC200-7, PC200-8M0, PC210, PC220-8M0, PC300-8M0, PC350-8.

Bulldozers/Loaders: D155AX, D65EX

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879