SPARKLING JCB JS70 Swing Gearbox – Durable Excavator Part

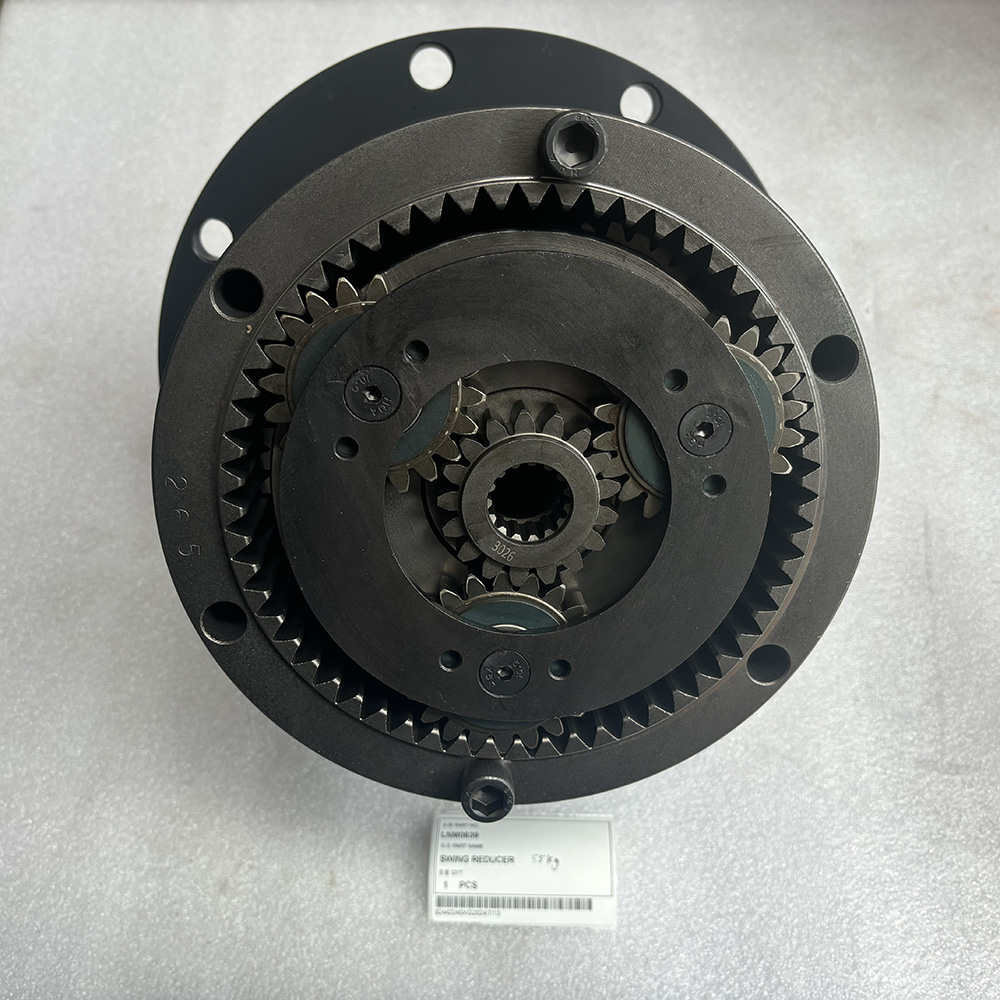

The JCB Swing Gearbox Assembly (suitable for JS70, PC60‑7, and PC70‑7/PC60‑7 excavators) is a precision-engineered swing reducer designed to deliver smooth and reliable rotational performance. Built to OEM standards (e.g., part no. LNM0639 / 201-26‑00130), this gearbox features hardened steel gears and robust bearings—ensuring durable operation under heavy load. It’s designed for easy drop-in replacement and reduces maintenance downtime. Ideal for construction, demolition, and excavation applications.

SPARKLING JCB JS70 Swing Gearbox – Reliable Power for Optimal Excavation

The SPARKLING JCB JS70 swing gearbox is engineered for superior performance, durability, and precision, designed to meet the demanding needs of your excavator operations. Manufactured by SPARKLING MACHINERY, a trusted name since 2013, this swing gearbox delivers exceptional reliability and stability, ensuring smooth, efficient swing function for your JCB JS70 excavator.

Crafted with meticulous attention to quality, the SPARKLING JCB JS70 swing gearbox stands out for its robust construction and precise engineering. It undergoes strict quality control processes to withstand tough working environments, reducing downtime and maintenance costs. Whether working on heavy construction sites or in challenging terrain, this gearbox supports consistent, powerful swing motion, enhancing your machine’s productivity and longevity.

At SPARKLING MACHINERY, we prioritize customer satisfaction by offering not only top-tier excavator parts but also expert technical support and tailored solutions. The JCB JS70 swing gearbox is compatible with genuine JCB specifications, ensuring seamless integration and peak performance. Our commitment to innovation and altruism guarantees that you receive a product that adds true value to your equipment.

With competitive pricing and a global distribution network, SPARKLING MACHINERY empowers you to maintain your excavator efficiently, minimizing downtime and maximizing operational efficiency. Choose the SPARKLING JCB JS70 swing gearbox for a dependable, high-precision swing system component you can trust.

Picture Show

FAQ

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

If you have any other questions, please write email to us or call us , we will reply you ASAP.

JCB Swing Gearbox Assembly for JS70, PC60-7 & PC70-7 Excavators – LNM0639

The JCB Swing Gearbox Assembly (suitable for JS70, PC60‑7, and PC70‑7/PC60‑7 excavators) is a precision-engineered swing reducer designed to deliver smooth and reliable rotational performance. Built to OEM standards (e.g., part no. LNM0639 / 201-26‑00130), this gearbox features hardened steel gears and robust bearings—ensuring durable operation under heavy load. It’s designed for easy drop-in replacement and reduces maintenance downtime. Ideal for construction, demolition, and excavation applications.

HIGH-QUALITY 282-8561 PISTON STD for Caterpillar Engine Equipment 303C CR, 304C CR Excavators

The HIGH-QUALITY 282-8561 PISTON STD is a premium engine core component meticulously engineered for Caterpillar Engine Equipment, specifically tailored to meet the precision combustion and durability demands of 303C CR and 304C CR Excavators. As a critical part of the engine’s combustion chamber, this standard-size (STD) piston converts fuel energy into mechanical power through linear motion, working in seamless coordination with the cylinder, connecting rod, and crankshaft. It ensures efficient combustion, optimal compression, and stable engine performance even during prolonged heavy-duty construction tasks.

Designed to perfectly align with Caterpillar’s engine architecture, it enhances machinery power output, fuel efficiency, and overall engine service life.

Key Features

· Custom-engineered for perfect compatibility with Caterpillar 303C CR, 304C CR Excavators

· Standard-size (STD) design to maintain original engine compression ratios and performance parameters

· Optimized crown profile for efficient combustion, reduced emissions, and maximum power output

· Enhanced thermal resistance to withstand high temperatures in the combustion chamber

· Strict adherence to Caterpillar OEM specifications for seamless integration and consistent engine functionality

Compatible Models

· Caterpillar Engine Equipment Excavators: 303C CR, 304C CR

Hydraulic Pump 31QC-10010 31QA-10021 K3V180DTP for Hyundai Excavator R420LC-9S R430LC-9SH

The 31QC-10010 and 31QA-10021 hydraulic main pump assembly is designed for Hyundai excavators R420LC-9S and R430LC-9SH. This pump is the core component of the excavator hydraulic system, responsible for supplying pressurized hydraulic oil to power the boom, arm, bucket, and other working functions. It is commonly used as a replacement for Kawasaki K3V180DTP axial piston pumps and is suitable for heavy-duty construction applications.

Technical Specifications

Part Type: Main Hydraulic Pump.

Model Identification: Specifically identified as a Kawasaki K3V180DTP-170R-9N62 or K3V180DTP series pump.

Purpose: Delivers hydraulic power for essential excavator functions, including digging, lifting, and rotating.

Compatible Equipment

This pump is a critical component for several heavy-duty Hyundai excavator models:

R430LC-9SH R420LC-9S R430LC-9

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EW140D EW160D EW160E EW180C 14567837 SENSOR SPARKLING MACHINERY

Part number 14567837 (also known as VOE14567837) is a speed sensor (often referred to as a speed transmitter or transmission sensor) designed for Volvo construction equipment.

Key Details

Function: It acts as a "data eye" for the machine's electrical system, monitoring transmission or machine speed to ensure precise operational control.

Alternative Part Numbers: VOE14509485.

Weight: Approximately 0.05 kg.

Compatible Volvo Models

This sensor is primarily used in wheeled excavators and some wheel loaders:

Wheeled Excavators: EW140D, EW160D, EW160E, EW180C, EW180D, EW180E, EW210C, EW210D, EW230C, and EWR150E.

Wheel Loaders: L45F, L45G, L50F, and L50G.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879