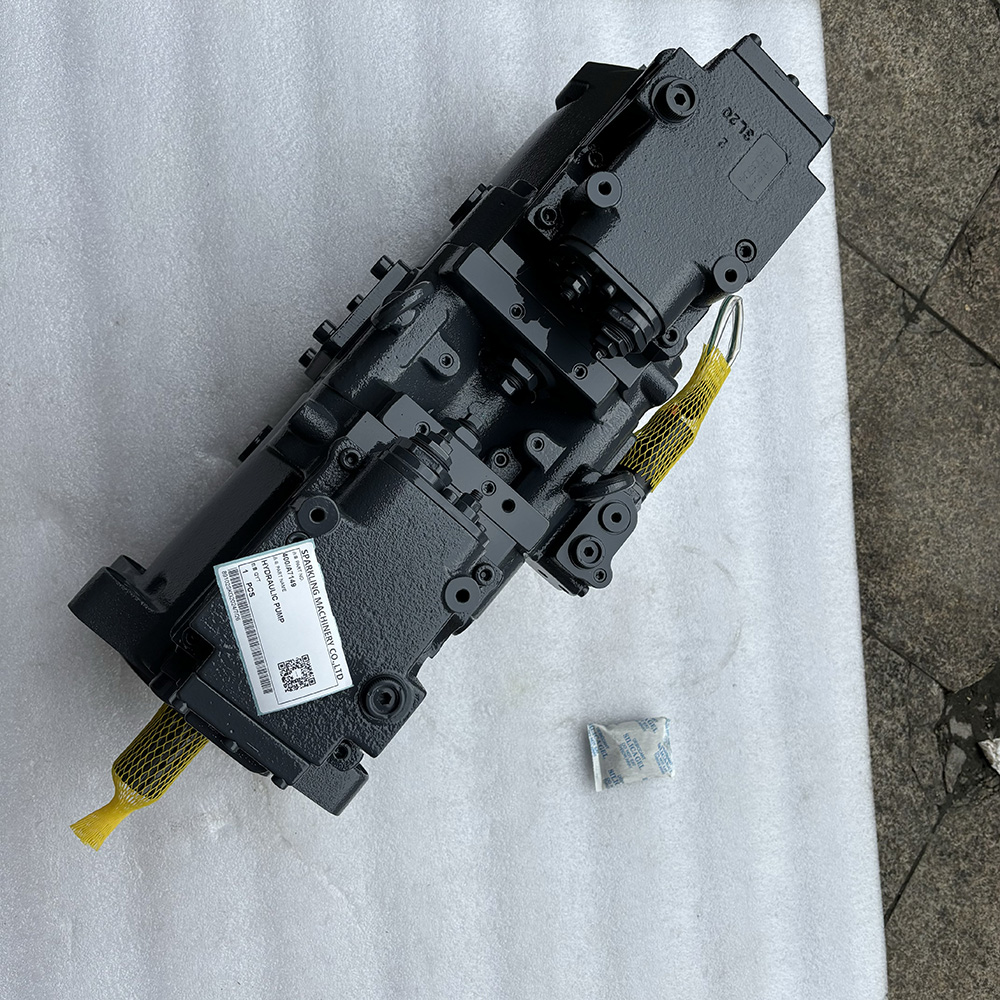

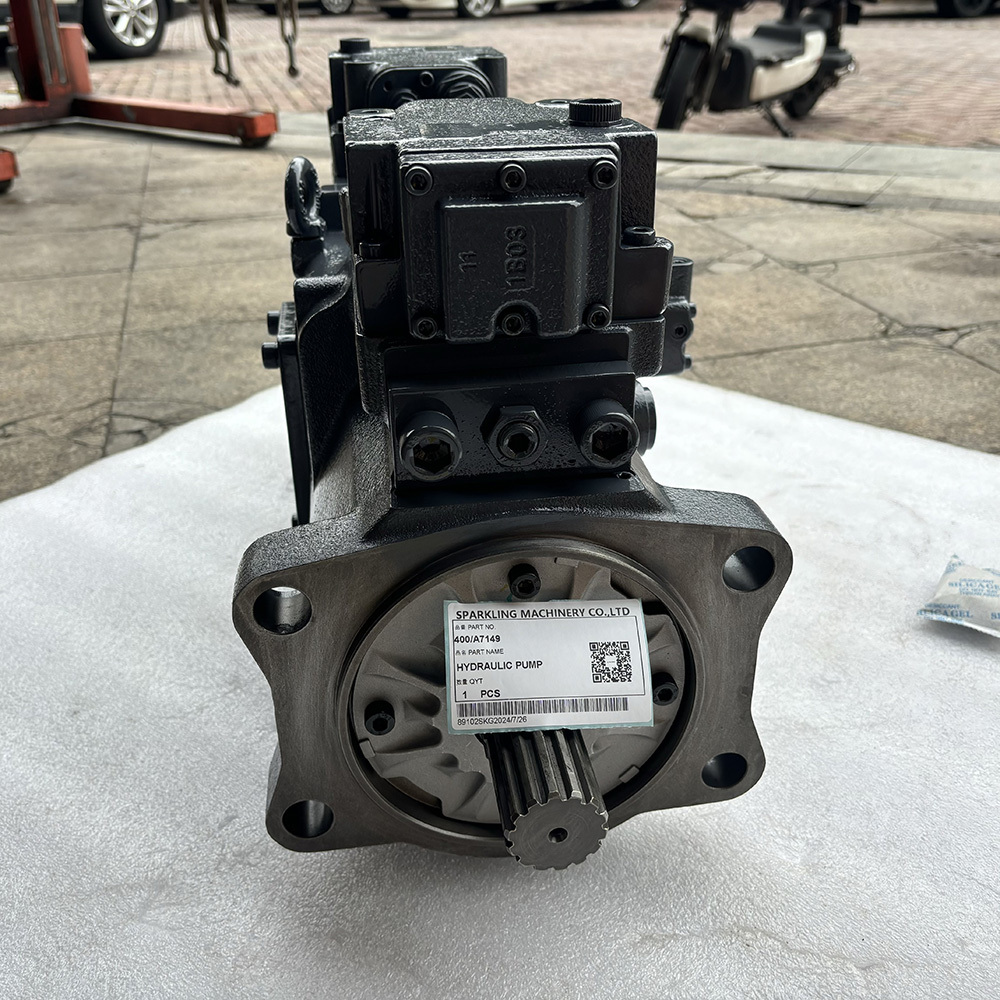

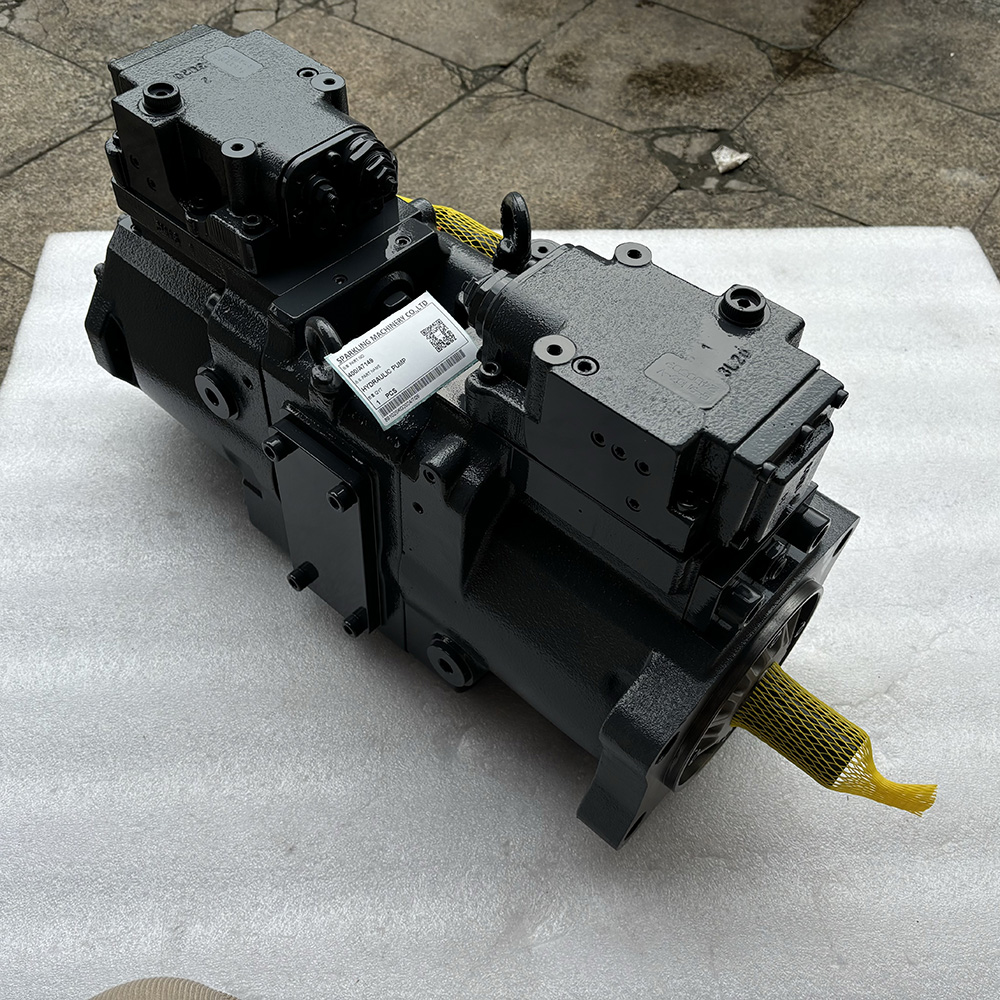

SPARKLING JCB Replacement Pump – Better Quality & Reliability

The 400/A7149 Hydraulic Main Pump Assembly is a high-efficiency, China-manufactured replacement pump designed to match or exceed original JCB standards. Engineered with precision and built using upgraded internal components, this pump ensures strong flow delivery, stable pressure, and reliable performance in heavy-duty construction and excavation applications.

It is a direct-fit solution for JCB models using this pump reference, providing excellent value without compromising on quality. Each unit is 100% factory-tested to guarantee durability and smooth operation under tough working conditions.

SPARKLING JCB Replacement Pump – Better Quality for Reliable Performance

SPARKLING MACHINERY, established in 2013, is a trusted name in high-quality excavator parts dedicated to stability, precision, and durability. Our JCB replacement pump brings you better quality matched with superior performance, engineered to meet the demanding needs of your excavator’s hydraulic system.

Designed with advanced manufacturing techniques and subject to strict quality control, the SPARKLING JCB replacement pump ensures long-lasting, reliable operation even under harsh working conditions. Whether you are on a construction site or tackling heavy-duty tasks, this pump delivers consistent hydraulic pressure and flow, maximizing your machine’s efficiency and minimizing downtime.

At SPARKLING MACHINERY, customer satisfaction is at the heart of our service. We provide tailored solutions and technical support to ensure seamless integration with your existing equipment. Compatible with a wide range of JCB excavator models, our replacement pump offers an excellent balance of quality and affordability, helping you reduce costs without compromising performance.

Choose the SPARKLING JCB replacement pump for better quality, unparalleled reliability, and peace of mind. Backed by our commitment to innovation, altruism, and continuous service, we support your operation every step of the way. Trust in a product designed with precision and crafted for excellence—because your machinery deserves the best.

Product Image

FAQ

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

JCB 400/A7149 HYDRAULIC MAIN PUMP ASSY CHINA MADE BETTER QUALITY

The 400/A7149 Hydraulic Main Pump Assembly is a high-efficiency, China-manufactured replacement pump designed to match or exceed original JCB standards. Engineered with precision and built using upgraded internal components, this pump ensures strong flow delivery, stable pressure, and reliable performance in heavy-duty construction and excavation applications.

It is a direct-fit solution for JCB models using this pump reference, providing excellent value without compromising on quality. Each unit is 100% factory-tested to guarantee durability and smooth operation under tough working conditions.

JOHN DEERE MADE IN CHINA SPARKLING MACHINERY NEW 350GLC 803M 853M RE555033 EGR VALVE

SPARKLING MACHINERY NEW 350GLC 803M 853M RE555033 EGR Valve is a dedicated emission control component exclusively designed for 350GLC excavators and 803M, 853M loaders. As a core part of the machinery’s Exhaust Gas Recirculation (EGR) system, it precisely adjusts the flow of exhaust gas back into the engine’s intake manifold—lowering combustion temperatures to reduce nitrogen oxides (NOx) emissions. This function is critical for meeting global emission standards (such as Tier 4 Final and Euro V) while preserving the engine’s power output and fuel efficiency during heavy-duty tasks like construction digging, material loading, and site grading.

- Engineered to match original equipment performance standards, it maintains stable valve operation even under harsh working conditions, including high exhaust temperatures, continuous machinery vibration, and exposure to exhaust contaminants. It prevents valve sticking or gas leakage, avoiding emission non-compliance and engine performance issues like power loss or increased fuel consumption. Backed by strict performance verification, it guarantees long-term reliability to support both environmental compliance and uninterrupted operation of 350GLC/803M/853M machinery.

Hydraulic Suction Manifold for Hitachi Excavator ZX120-3 ZX200-3 ZX330-3 ZX470-3 1033052 1026258

Our premium Hydraulic Pump Suction Manifold (Tee Tube) is engineered specifically for Hitachi ZAXIS-3 series excavators. This critical component (Part No. 1033052 / 1026258) ensures a seamless connection between the hydraulic oil tank and the main pump, guaranteeing stable fluid flow and optimal system pressure.

Key Features:

Exact Fit: Designed as a direct replacement for Hitachi part numbers 1033052 and 1026258, ensuring hassle-free installation.

Durable Construction: Manufactured from high-grade aluminum/alloy materials to withstand high pressure and resist corrosion in harsh working environments.

Enhanced Efficiency: Optimizes hydraulic suction to prevent cavitation and extend the service life of your main pump.

Wide Compatibility: Perfectly compatible with Hitachi ZX120-3, ZX200-3, ZX330-3, ZX350-3, and ZX470-3 models.

Specifications:

Part Name: Hydraulic Manifold / Suction Pipe Connector / Tee Tube

Part Numbers: 1033052, 1026258

Application: Hitachi ZAXIS Excavator Hydraulic System

Hyundai MADE IN CHINA SPARKLING MACHINERY NEW R220-9 21Q6-33402 MONITOR

SPARKLING MACHINERY NEW R220-9 21Q6-33402 Monitor is a premium China-made intelligent control component specifically designed as the core monitoring unit for R220-9 excavators. Serving as the "information hub" of the machinery, it provides real-time display of critical operational data such as engine speed, hydraulic pressure, fuel consumption, and system alerts, enabling operators to monitor equipment status comprehensively and ensure safe, efficient operation.

Engineered to original standards, it delivers clear visual feedback and responsive data updates even in harsh working environments, from dusty construction sites to high-vibration conditions. With intuitive interface design and reliable performance, it facilitates quick troubleshooting and operational adjustments, minimizing operational errors and optimizing equipment productivity. Backed by strict quality verification, it ensures consistent performance to support uninterrupted machinery operation.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879